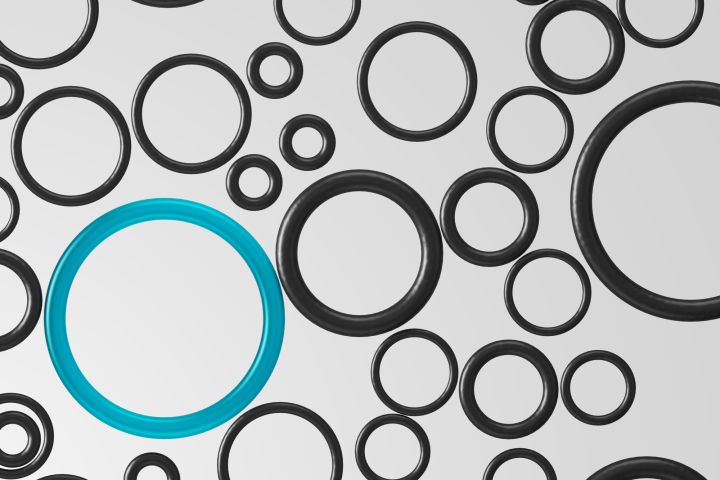

High quality sealing solutions for e-powertrains

Datwyler’s range of sealings for electric vehicles with three important solutions for e-powertrains.

Datwyler’s range of sealings for electric vehicles with three important solutions for e-powertrains.

Find out how Datwyler ensures the highest quality of O-rings by using the latest production equipment, Datwyler’s production system and co-engineering capabilities.

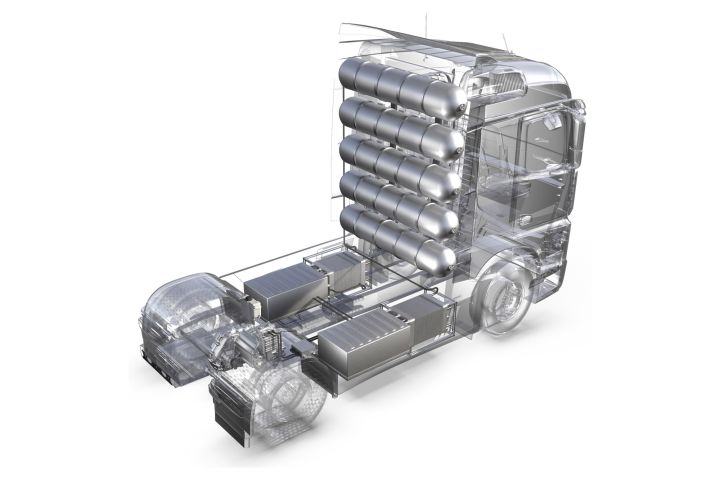

Datwyler has expanded its capabilities to support customers transitioning to hydrogen fuel cell technology.

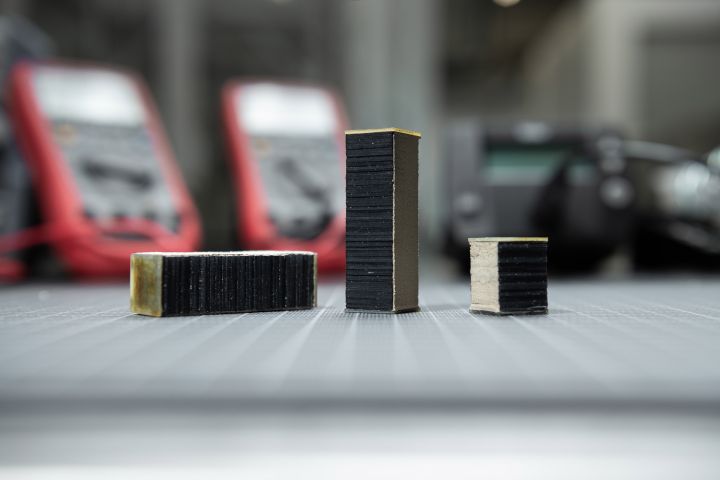

Different testing methods of system-critical elastomer components with fire-resistant material to prevent thermal runaway in battery systems of electric vehicles.

One of Datwyler’s key ESG focus topics is Ecodesign, a unique sustainability concept that ensures the environment is at the heart of every aspect of product development.

Datwyler is expanding its O-rings production capabilities with new molding machines installed at its sites in China and Mexico.

Discover how Datwyler’s materials and components are transforming the performance of batteries to make electric vehicles fit for the future.

For e-powertrain applications a wide variety of sealing solutions are required, as there are multiple surfaces that must be sealed effectively. We have developed a number of solutions for these sealing challenges.

Datwyler has a leading role in producing materials and components in the most sustainable way possible, while advancing the mobility sector to become even more efficient and eco-friendly.

Datwyler is further enhancing its global capabilities in O-ring development and production with the transfer of its state-of-the-art cold runner injection molding technology to Asia and North America.

Datwyler, together with the development partner Empa, has developed and patented an industrial process for surface modification of microfibrillated cellulose (MFC).

At the 31st Aachen Colloquium for Sustainable Mobility, Datwyler, FEV Europe GmbH and the Fraunhofer UMSICHT presented a detailed paper on the development of the BiFoilStack – a novel cell and stack design with compound-foil-based bipolar plates for heavy-duty fuel cell systems.

Visitors will be able to interact directly with Datwyler’s latest innovations in areas such as Electroactive Polymers (EAP) for interiors applications, Thermal Interface Materials (TIMs) for battery systems and Liquid Silicone Rubber (LSR) for e-powertrain solutions.

Ecodesign as initiative for a more sustainable product development process.

Datwyler is strengthening its position with the innovative future technology of electroactive polymers and has secured this with corresponding patents.

The engineering process is a core point of focus as the mobility industry transitions from ICE to electrification. The level of expertise required to ask the right questions at the right time is very high.

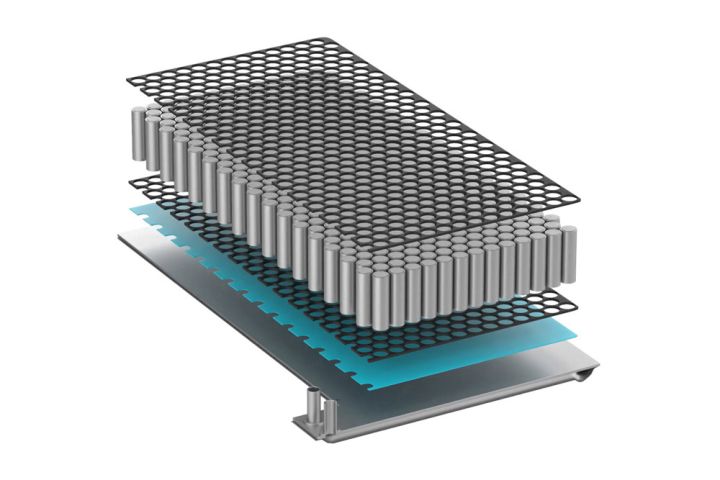

Datwyler has developed thermal interface materials focusing on stand-alone gasket solutions for battery systems.

Datwyler has launched new, dedicated Technology & Innovation Labs in Schattdorf, Switzerland, comprising a series of specialist laboratories, to further support customers globally.