Healthcare

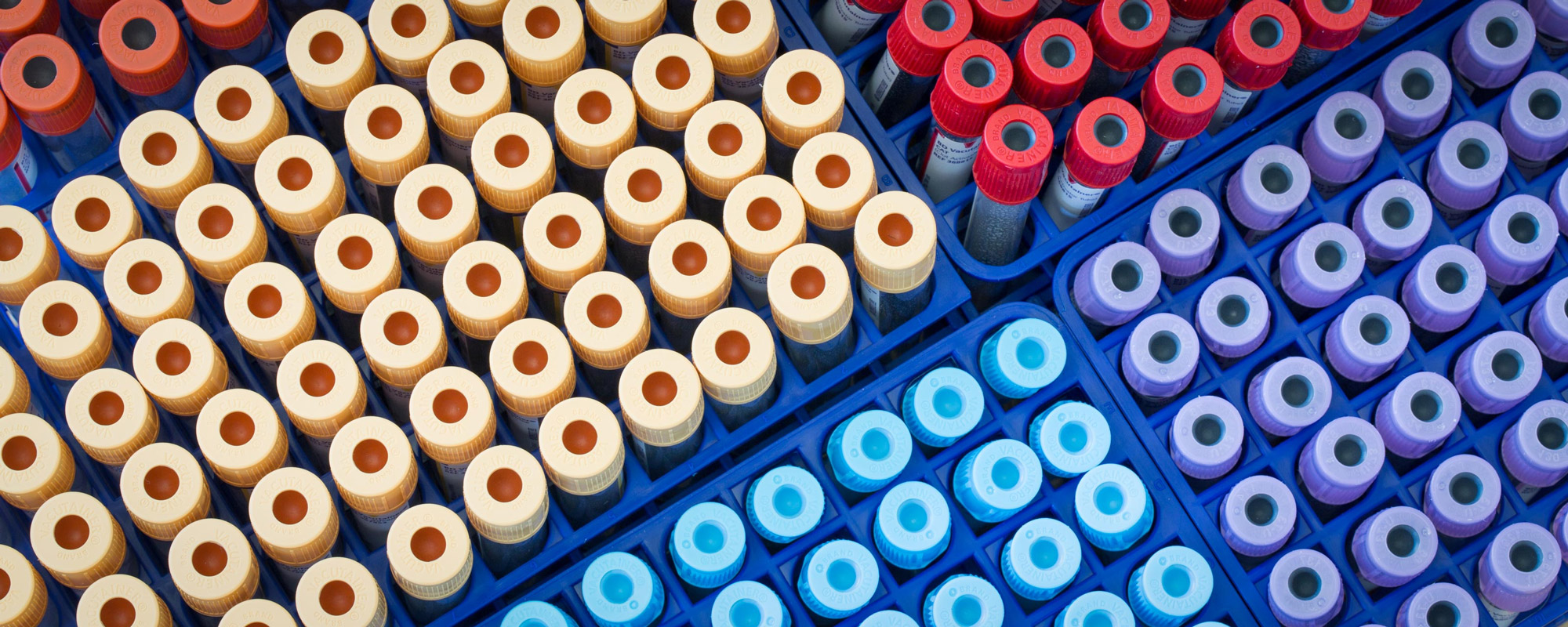

Committed to quality and safety. Our Healthcare offering for the pharmaceutical and biotech markets

The pharmaceutical and biotech markets require high-end quality without compromise. As a Swiss-based, leading supplier and key player in the global healthcare industry, Datwyler is a global thought leader with more than 100 years of experience and a good intuition for future trends.

We take great responsibility to help improve patients’ lives and see ourselves as a vital link between our customers and their patients – together, we create a safe and innovative healthcare environment of tomorrow. Our state-of-the-art solutions for parenteral drug packaging are supplied to leading pharmaceutical and biotech companies worldwide.

At Datwyler, we are dedicated to meeting customer expectations by guaranteeing the highest level of quality and safety and continuing to make investments aimed at meeting the ever-changing regulatory requirements of the industry. Thanks to our sophisticated product know-how, high-quality manufacturing processes provided on a global scale, and our strong partnerships, we offer best-in-class solutions and enable our customers around the globe to realize their full healthcare potential.

More about

Latest news

FirstLine® – Datwyler’s best-in-class manufacturing standard

Datwyler Healthcare CEO, Dirk Borghs, discusses Datwyleru2019s FirstLineu00ae manufacturing standard, recent investments and expansions of the companyu2019s global footprint, and its highest quality coated elastomers for sensitive drugs.

upcoming events

Resources

Datwyler in the media

Join Us

Visit our Datwyler Healthcare social media channels and join us on our journey.