Leading provider of high-quality, system-critical elastomer components

With recognized core competencies in solution design, material know-how and product industrialization, we are a strategic engineering partner for innovative systems in Healthcare, Transportation & Electronics, General Industry and Food & Beverage. Read more about us.

Softpulse

Boosting your wearable application to the next level with SoftPulse®

Soft dry electrodes can be used for easy, comfortable, and long-term monitoring of bio-signals like EEG, ECG, EMG and EOG for consumer as well as medical applications.

Prefilled Syringes

NeoFlex™ Plungers: Superior Drug Delivery Solutions

Datwyler’s NeoFlex™ Plungers: The Reliable Choice for Prefilled Syringes and Cartridges. Our premium plungers offer superior performance and compliance for self-administration devices, meeting the highest industry standards.

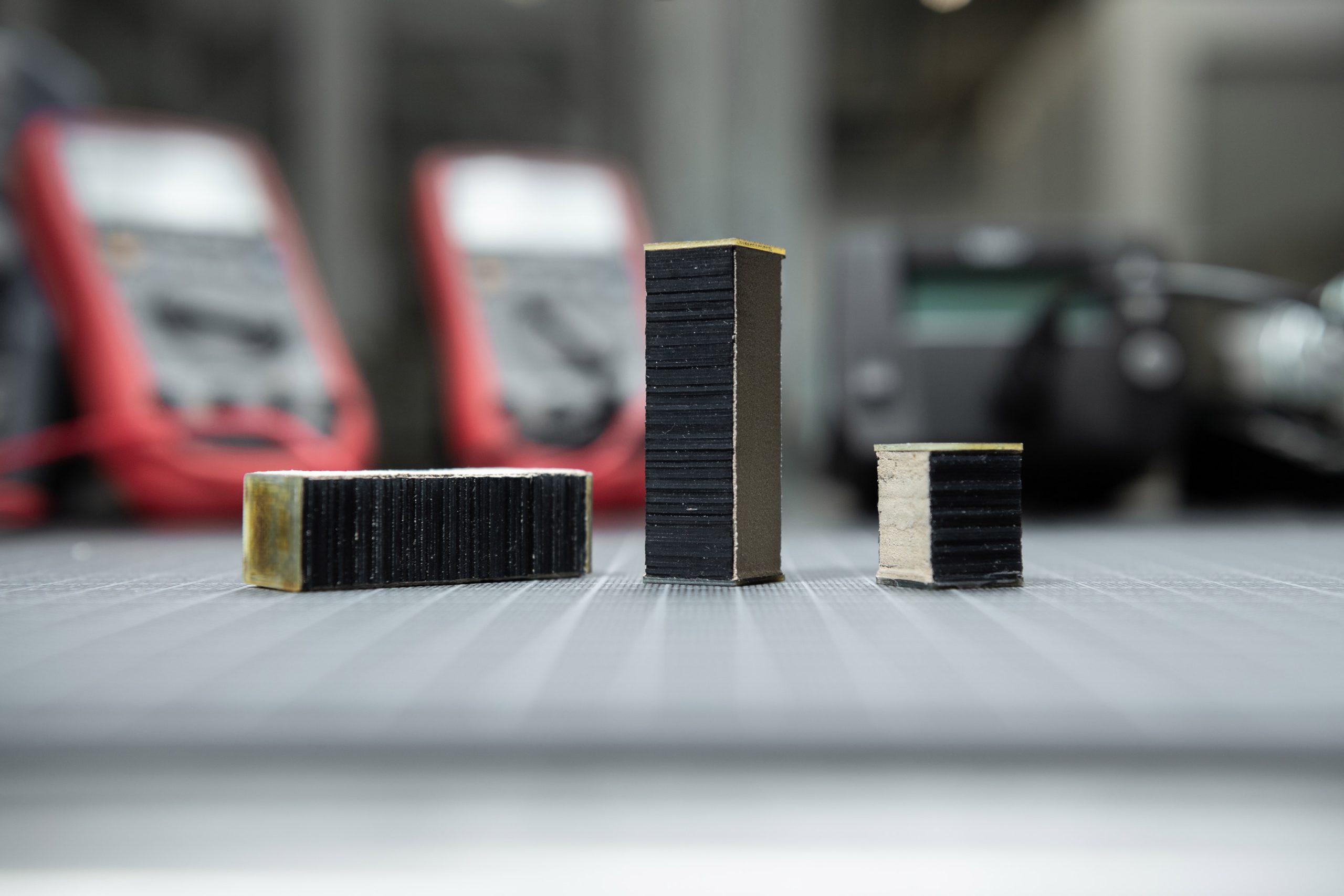

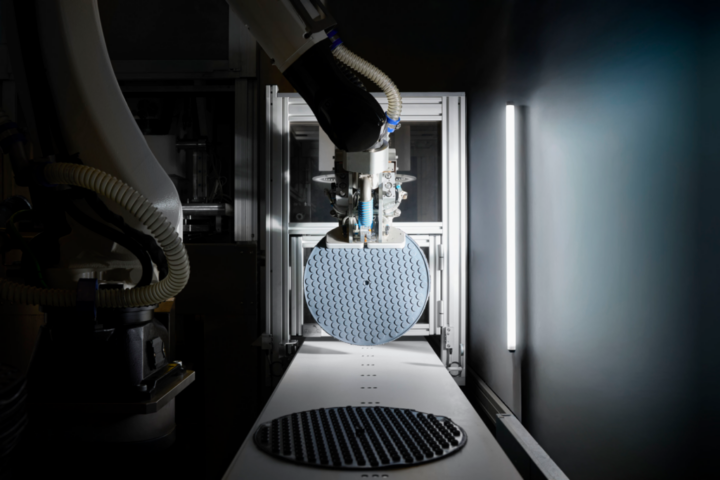

Electro Active Polymers (EAP)

Advanced manufacturing of a novel actuation technology

Actuators are mechanical components that allow the transformation of electrical energy into mechanical energy and enable a multipurpose and efficient operation.

Latest news

Datwyler has successfully completed the acquisition of a majority stake in Capsul’in as announced in December 2025.

In the 2025 financial year, Datwyler generated revenue of CHF 1’100.5 million. Adjusted for negative currency effects of -3.7%, the company achieved organic growth of 3.1%. Due to these currency effects, reported revenue was overall 0.6% below the prior-year level.

Datwyler has received validation of its short-term, Group-wide greenhouse gas reduction targets by the Science Based Targets initiative (SBTi).

The Swiss Datwyler site in Schattdorf, Switzerland, took 1st place in the Swiss Arbeitgeber Award 2026 in the category for large companies (250–999 employees).

Datwyler has signed an agreement to acquire 51% of Capsul’Invest SA und Brain Corp SA (together operating as Capsul’in), a leading provider of aluminum coffee capsule solutions headquartered in Luxembourg with annual revenues of approximately EUR 90 million.

Employee Spotlight

Dynamic organization

I appreciate working in a dynamic, fast-paced organization that supports ownership. It’s rewarding to play a role in producing components that contribute to every person’s health.

Frank Schoubben

Head of Technology US

Sustainability

Proactive chemical compliance management

Datwyler goes beyond legal requirements worldwide. Increase of occupational safety of our employees. Reduction of environmental impact of our products. Natural rubber accounts for less than 1% of rubber raw materials. Customers benefit from particularly safe elastomer compounds.

Sustainability

Corporate Social Responsibility activities in India

Inauguration of renovated Kindergarten in Kesurdi area, India

Employee Spotlight

A multidisciplinary and friendly organisation

I am very pleased to be part of a very engaging global organisation that motivates and supports innovation. An organisation that has strong core values that result in continues improvement towards both its employees and customers.

Hediyeh Zahabi

Manager Material Development

Sustainability

Closed water circuit in Indian health care plant

The washing of the high quality health care components requires considerable amounts of water. With the closed water circuit in its Indian plant Datwyler saves significant amounts of water in an area where water is scarce.

Closed water circuit at Datwyler plant in Kesurdi, India

Upcoming Events