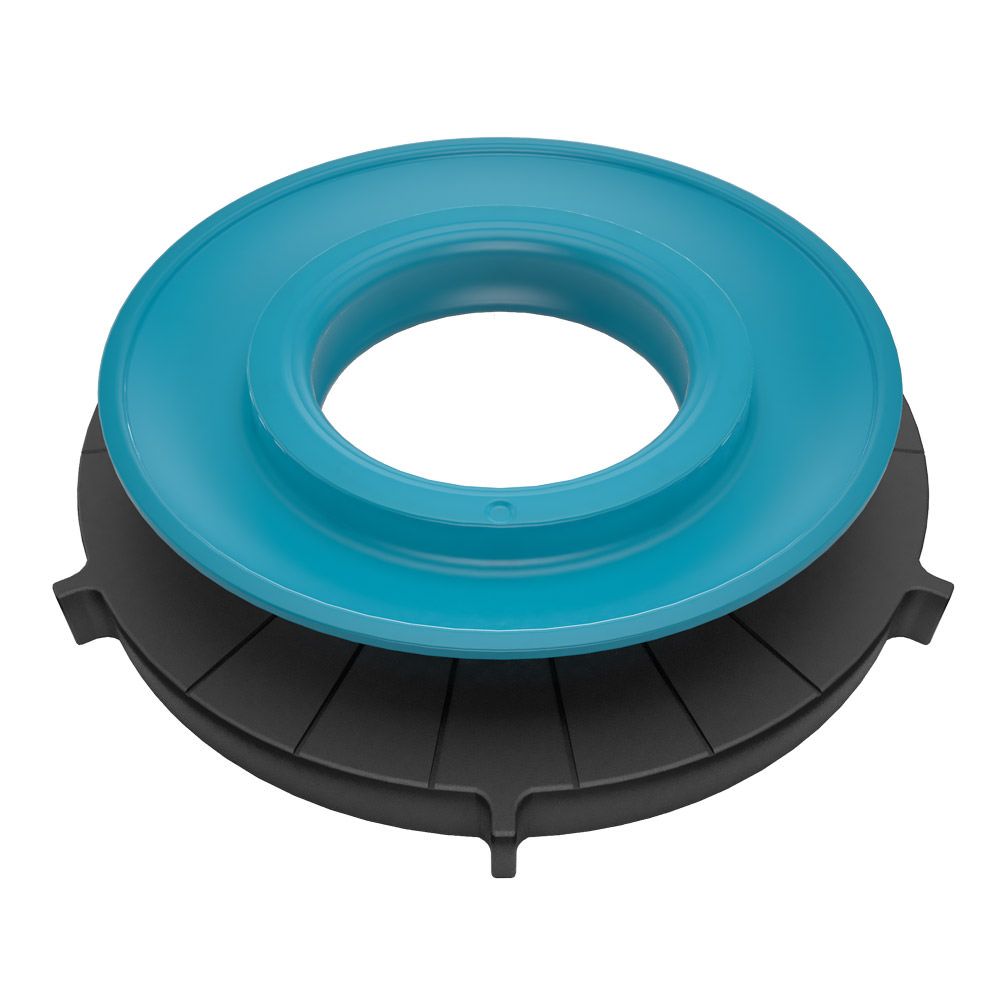

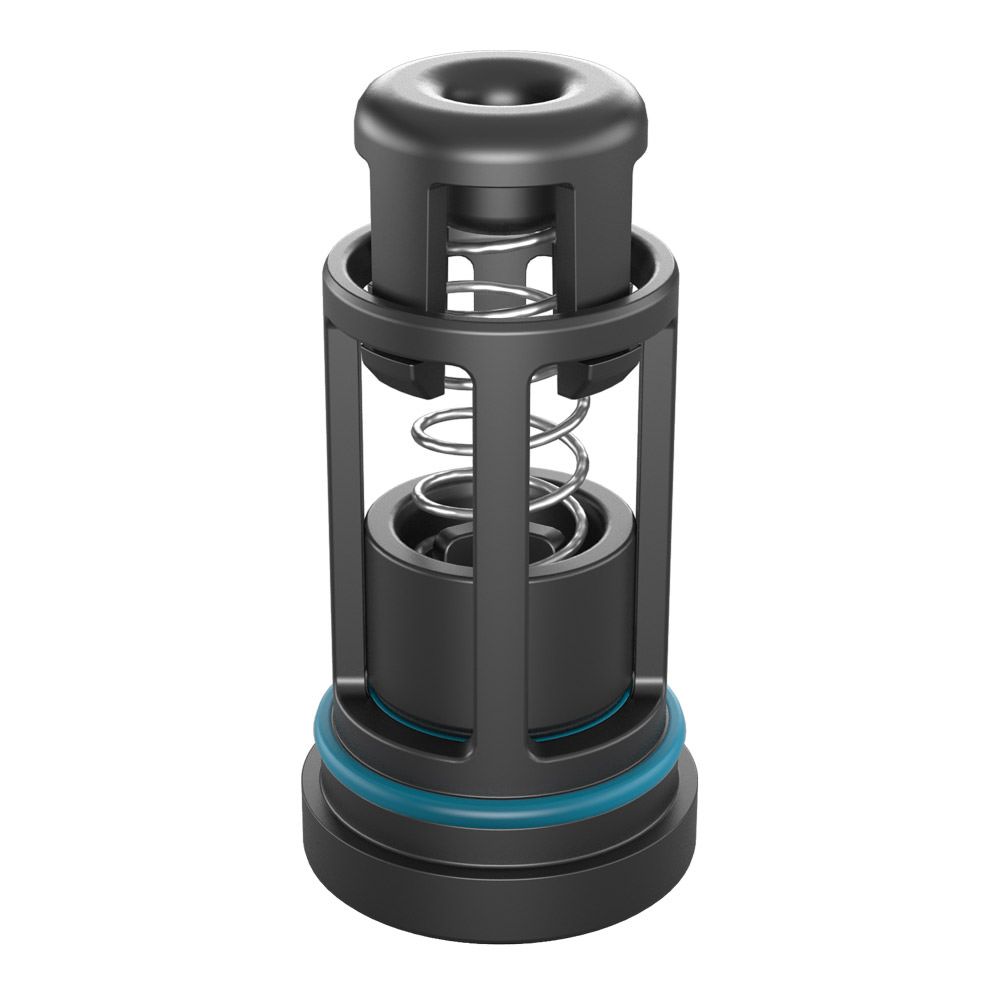

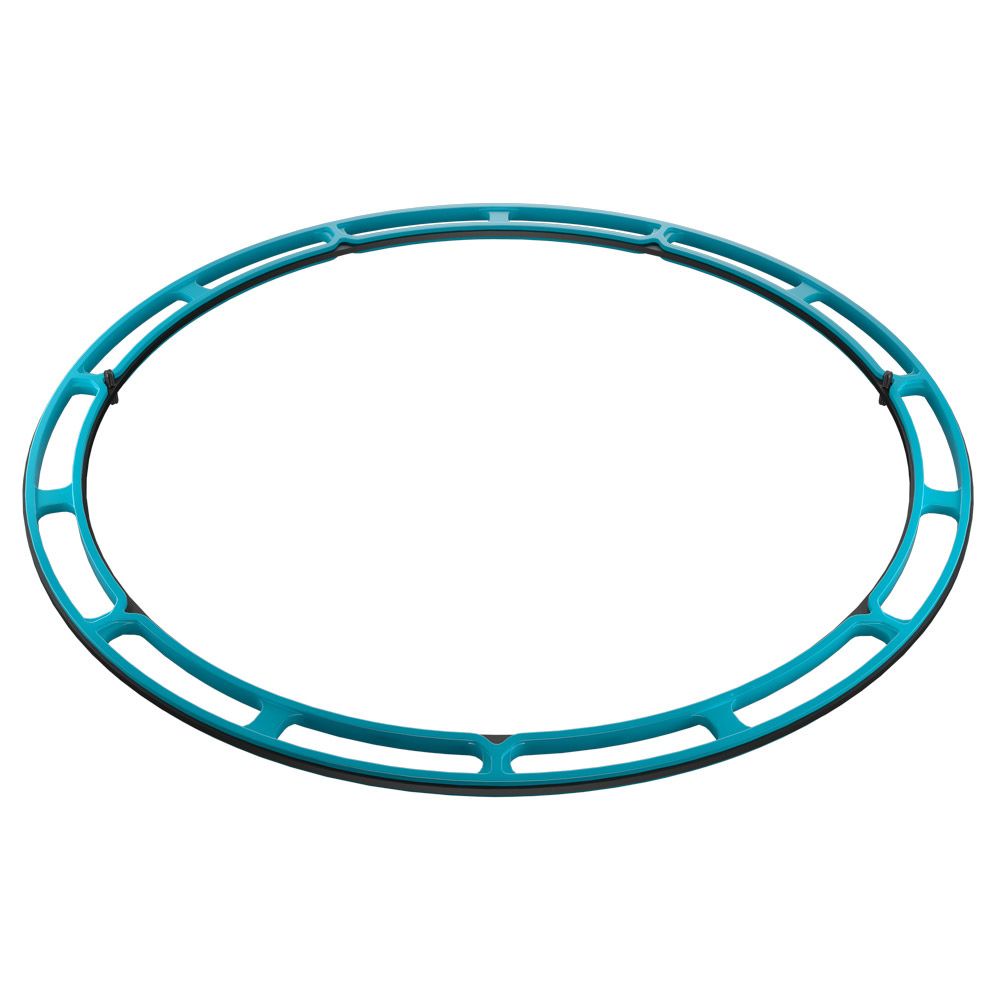

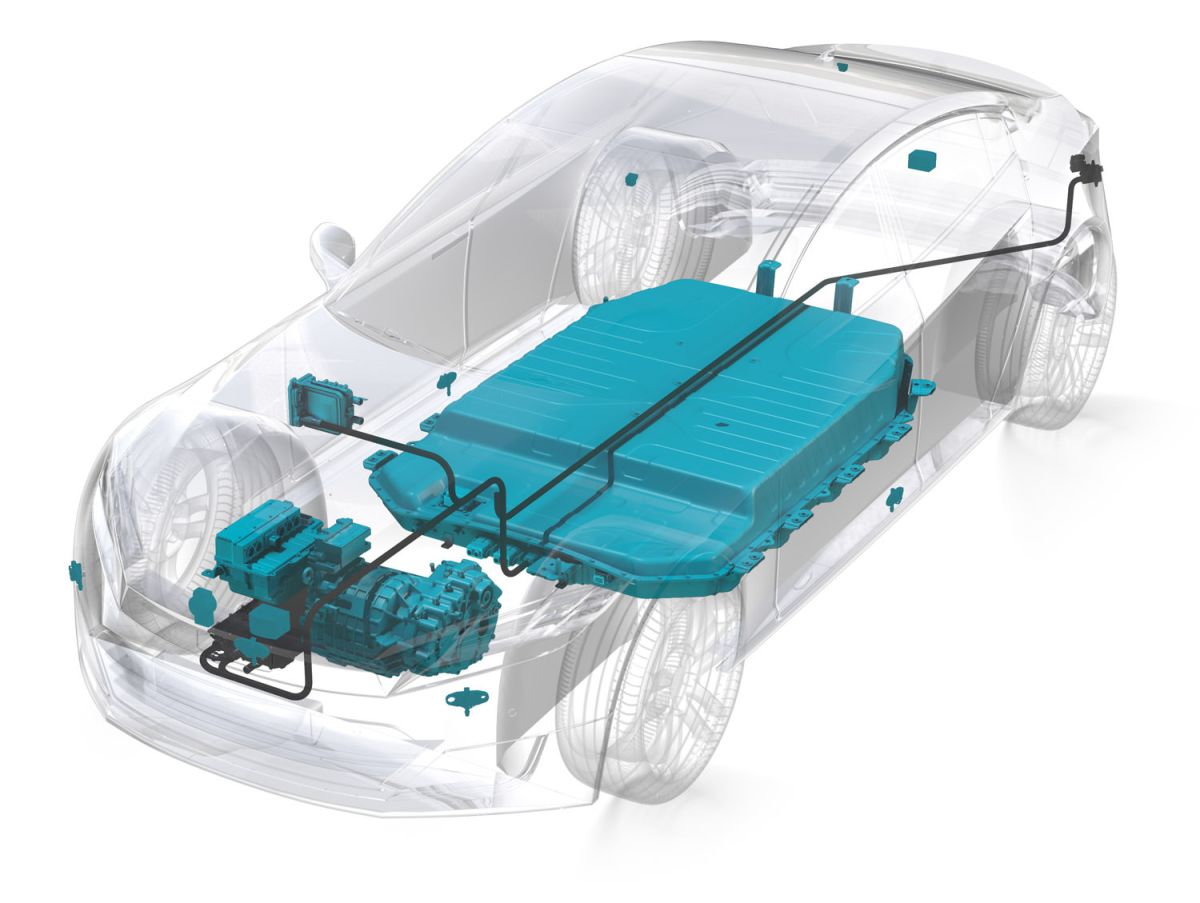

Datwyler is increasing its LSR and thermoplastic portfolio, producing customized multi component sealing solutions for a wide range of mobility systems, including batteries, sensors, electric drive motors, power distribution units, high voltage connectors, and drivetrains. With the development of ADAS (Advanced Driver Assistance Systems), Datwyler’s proprietary materials and tooling will play a key role in advancing this technology further, as we work directly with customers to design, test, and produce complex parts precisely tailored for their application.

Datwyler advantages

In-house tooling

Datwyler is one of the few global companies with a specialist in-house tooling center. This gives us full control over the production of LSR and thermoplastic components, resulting in shorter lead times and greater flexibility for our customers.Simulation expertise

We pride ourselves on our years of experience in product and mold flow simulation, using the latest structural mechanical analysis and virtual molding technology. This results in multi-component parts produced in optimum processing conditions that fulfil all customer and application requirements.Global support

From prototyping to full production, Datwyler has a worldwide network of facilities and experts. Whether it’s our competence center in Germany or our production plants in China and Mexico, we offer full support at every stage of your LSR journey.Zero waste process

High-precision tooling and an in-house cold runner system for the injection molding process results in zero waste, improving production efficiency and product sustainability.

We have over 30 years of experience in thermoplastics and LSR technology, with specialist expertise in simulation, tool manufacture, and part production. This gives us a strong competitive advantage in supporting our customers.

Alwin Hess

Sales Engineer

Contact

For more information about the applications of liquid silicone rubber and how Datwyler can help you achieve optimum performance, please get in touch.