Mobility

Local-for-local on a global scale

Article | March 29, 2022

In the current climate it is little wonder that one of the highest priorities for the mobility industry is protecting its supply chains. Lockdowns, travel restrictions and political decisions have all had an impact in recent years. As a result, the ability to deliver a local-for-local service at a global level has become highly desirable. Of course this requires a great deal of planning and investment on the part of the supplier. However, those that are prepared to do so in order to deliver for their customers will only strengthen the relationships they have in the regions they serve.

Datwyler’s local-for-local approach

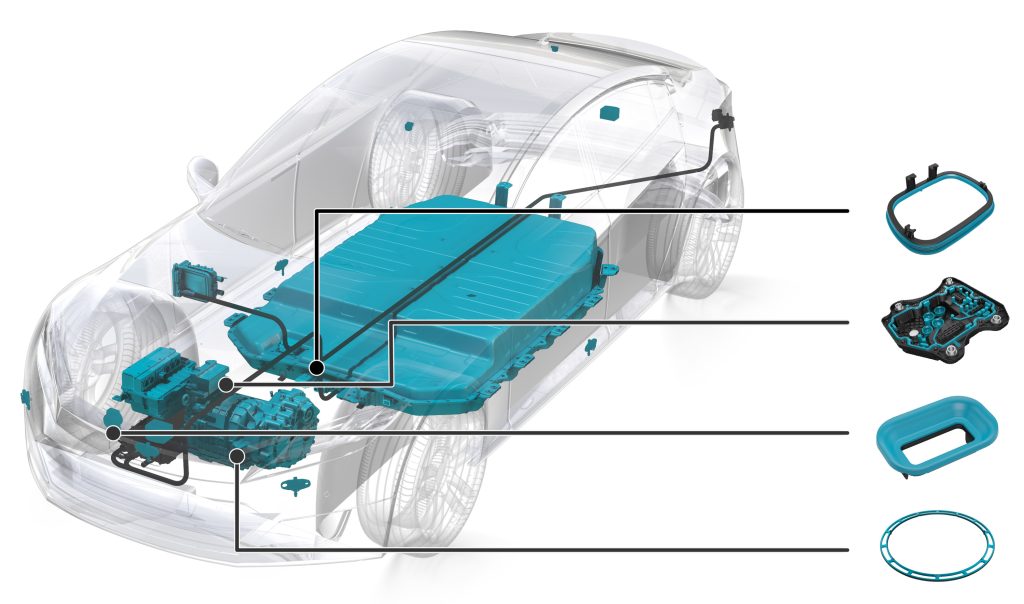

At Datwyler, Liquid Silicone Rubber (LSR) and Thermoplastic (TPL) components are driving this local-for-local approach, as demand continues to surge as a result of the electrification of vehicles. Mobility manufacturers globally are forging ahead with research, design and development and their willingness to wait for components to make long journeys from other regions is limited. The requirement is to deliver fast to the highest levels of quality and that is why our strategy continues to be local with a global reach.

LSR technology capabilities in China starting 2022

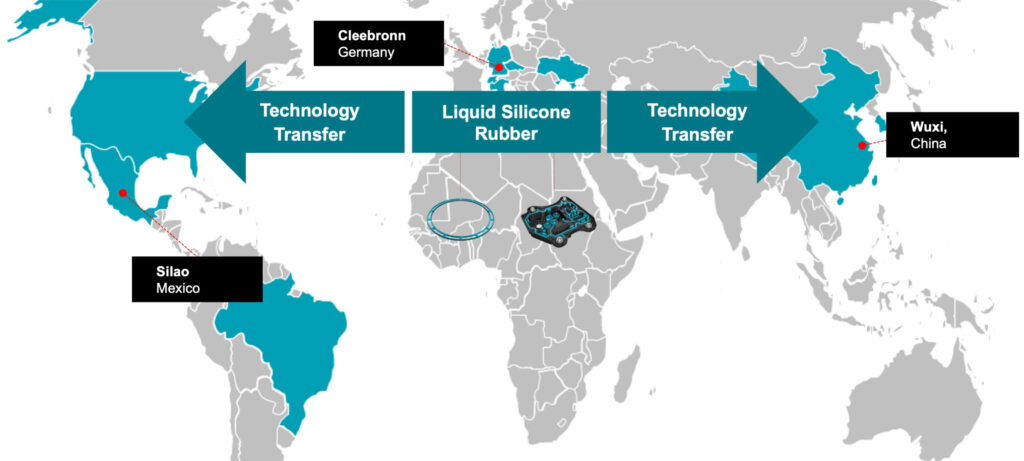

If we take the Asia Pacific region as an example, in 2020 we commenced the transfer of LSR technology capabilities to Wuxi in Jiangsu province. China in particular is a region of key strategic importance to all of our customers. As a driving force in the move towards new mobility applications the decision to enhance our capabilities there has been straightforward. Our LSR technology will come online in Wuxi in early 2022 and will be a key addition to our portfolio in the region. This will reduce transport and logistics costs for our customers and also enable components to reach customers faster and in a way that has less impact environmentally.

Same in-house services in all our global facilities

It is not just the Asia Pacific region this applies to. With its facilities in Silao, Mexico and Cleebronn, Germany, Datwyler is able to deliver that same local-for-local service in the NAFTA and European region. Core to this is the fact that everything we produce is controlled in-house. From simulation and mold flow analysis to manufacturing and validating tooling, we have the expertise and we own the processes, enabling us to deliver enhanced flexibility in a manner that is agile and versatile.

For example, our inhouse toolshop in our competence center in Germany is the hub of our LSR portfolio. Designs from around the world are analyzed and optimized here and precision tooling produced and validated on equipment that mirrors that of our global facilities.

Essentially, this means we are able to use our broad knowledge and synergies to deliver a global service from a single location in regards to tooling, which is then executed in terms of production by the facilities and support networks we have established locally.

Supply chain security and the ability to deliver consistency of parts consistently has never been more important.

With a firm focus on what is best for our customers, we at Datwyler will continue to enhance our offering and our portfolio in a manner that is as sustainable as it is reliable.