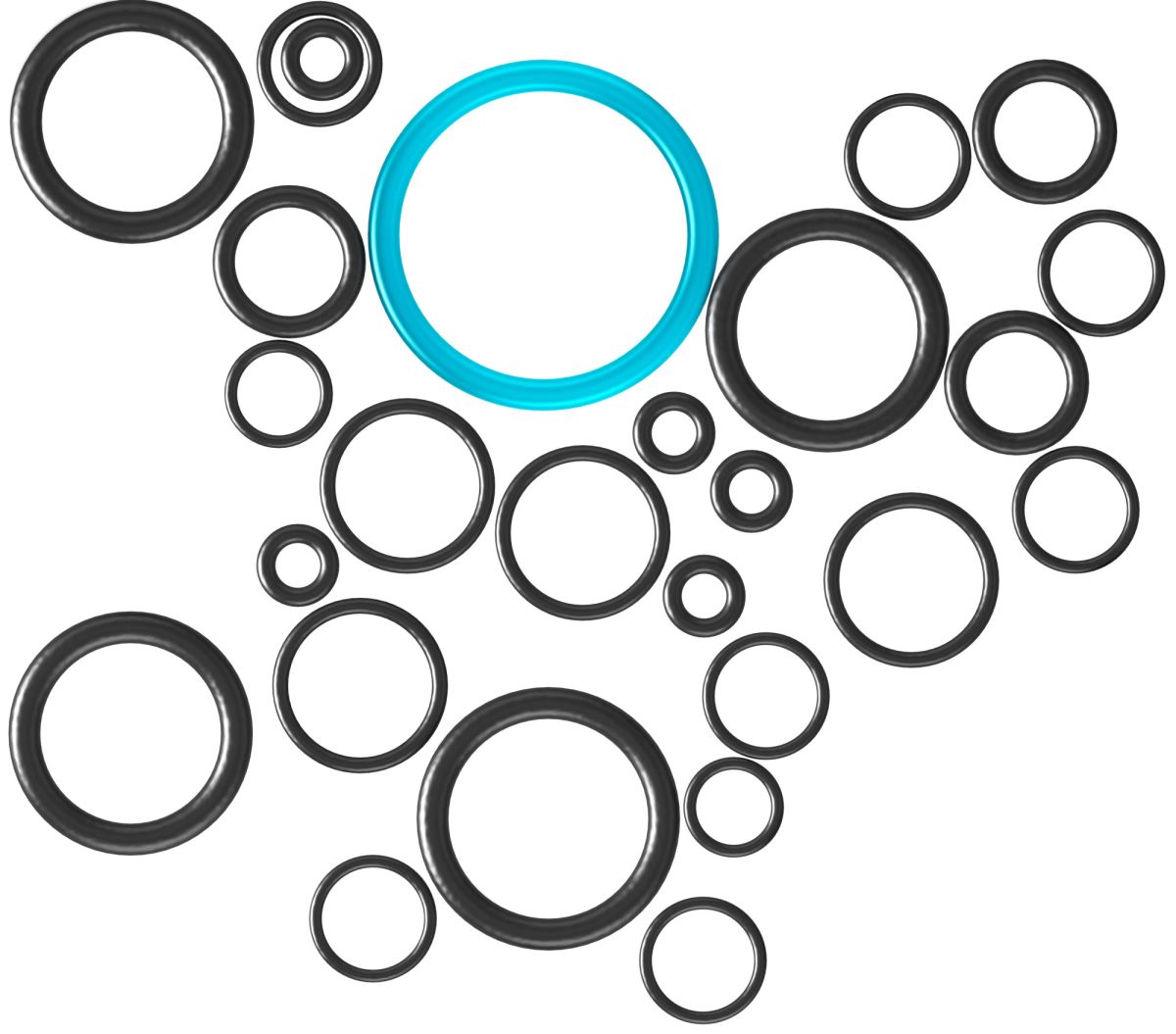

How to deliver the ideal O-ring solution

Find out how Datwyler ensures the highest quality of O-rings by using the latest production equipment, Datwyler’s production system and co-engineering capabilities.

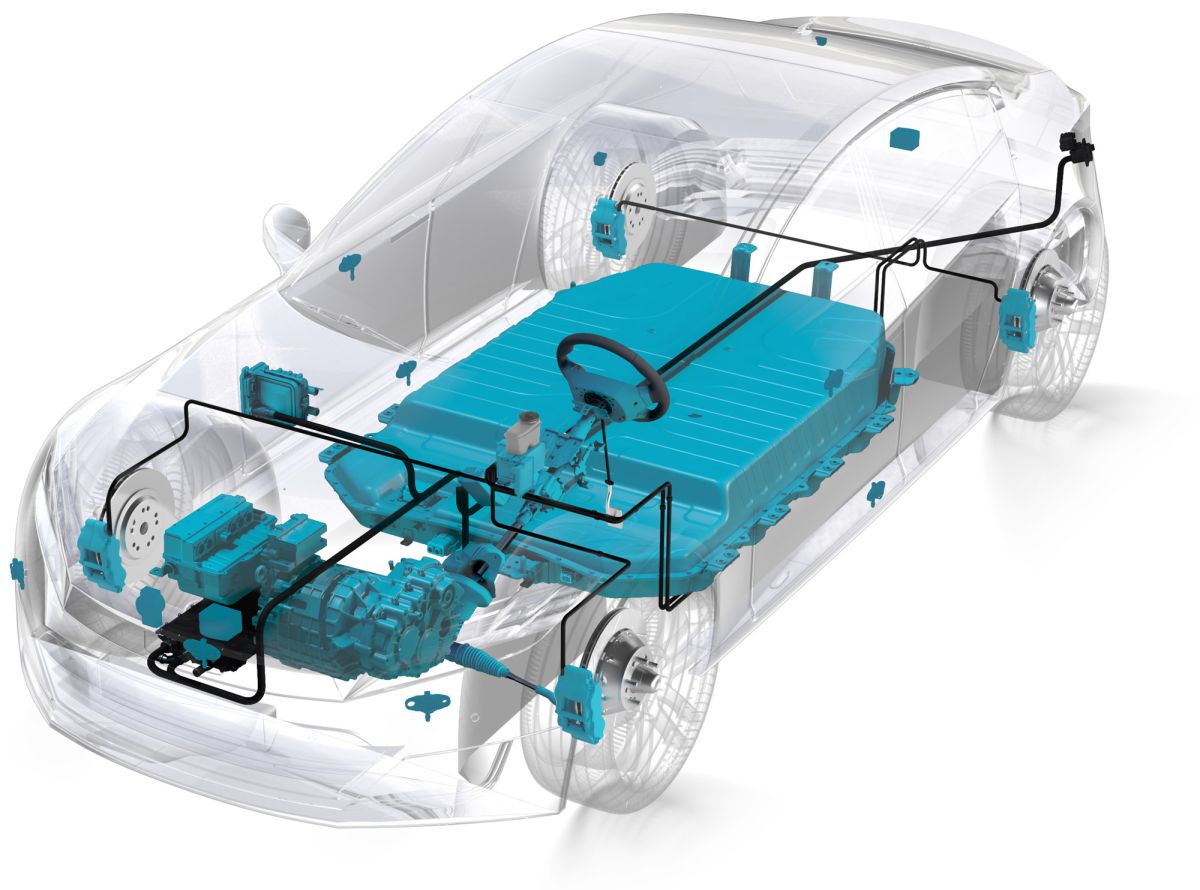

In the mobility industry, O-rings may be small in size but their importance is huge. Present in almost every area of conventional, hybrid, and electric vehicles, their precision, durability, and highly customizable properties make them core elements of a wide range of systems, from conventional applications such as braking, fuel management, transmission, and steering to new applications such as battery cooling and fuel cell technology.

As the trend for electrification gathers pace, the number of applications that require elastomer O-rings is increasing exponentially. Alongside crucial roles in gear and clutch systems, anti-lock braking systems, power steering, shock absorbers, fuel pumps, solenoid valves, and battery and cooling systems, you can now add Advanced Driver Assistance Systems (ADAS), fuel cells, sensors, and electrified braking, connection and powertrain systems. Datwyler not only offers materials and components with abrasion-optimized compounds and high- and low-temperature resistance, but also a range of surface treatments to improve your production and assembly processes, as well as the efficiency of your application.

| Applications | EPDM | NBR | FKM | VMQ | AEM | LSR | HNBR |

|---|---|---|---|---|---|---|---|

| Electrification | ○ | ○ | ○ | ○ | ○ | ○ | |

| Emission control | ○ | ○ | |||||

| Brake systems | ○ | ○ | |||||

| Steering/Suspension | ○ | ○ | ○ | ○ | |||

| Transmission | ○ | ○ | ○ | ○ | ○ | ||

| Battery systems | ○ | ○ | ○ | ○ | |||

| Thermal management | ○ | ○ | ○ | ○ | ○ | ||

| HV connection | ○ | ○ | ○ | ||||

| Energy storage/Fuel management | ○ | ○ | ○ |

Full-service co-engineering partner

From first designs to final production, we offer a number of co-engineering services that involve close cooperation with our customers, using our global network of experts to develop the ideal solution.

In-house simulation

Datwyler has the full range of in-house simulation technology and expertise, providing you with highly accurate data and analysis of material performance, component mechanical behavior, and mold optimization before production. This not only reduces the time to market but delivers a solution that’s been extensively tested and proven. Find out more about our simulation services here.

Surface treatments

We offer a wide range of surface treatments, whether it’s to increase stability within the application environment, improve the efficiency of a production line process, or simply add a different color.

Abrasion testing

Our abrasion testing service can replicate a real-world application using specialized equipment under laboratory conditions, enabling the behavior of parts to be observed.

High cleanliness

As a global group with many divisions, Datwyler can call upon the expertise of other areas of our business to produce the best results according to precise customer specifications. This is especially relevant for cleanliness, which our Pharma division has particular experience in. We are also pioneers in the automotive sealing sector with our Lean and Clean manufacturing facility in Schattdorf, Switzerland.

Automated inspection

We operate a number of automated inspection processes using the latest monitoring technology, which results in the highest level of quality and the lowest number of defects.

In the area of O-rings, we can offer whatever our customer needs. We really have no limits. Our customers all receive a large amount of knowledge and capacity in terms of experts, developers, instrumentation testing, and device process trials.

Richard Katona

Head of Sales Americas

For more information about Datwyler O-rings and how we can work with you to develop the ideal solution, please get in touch.