High quality sealing solutions for e-powertrains

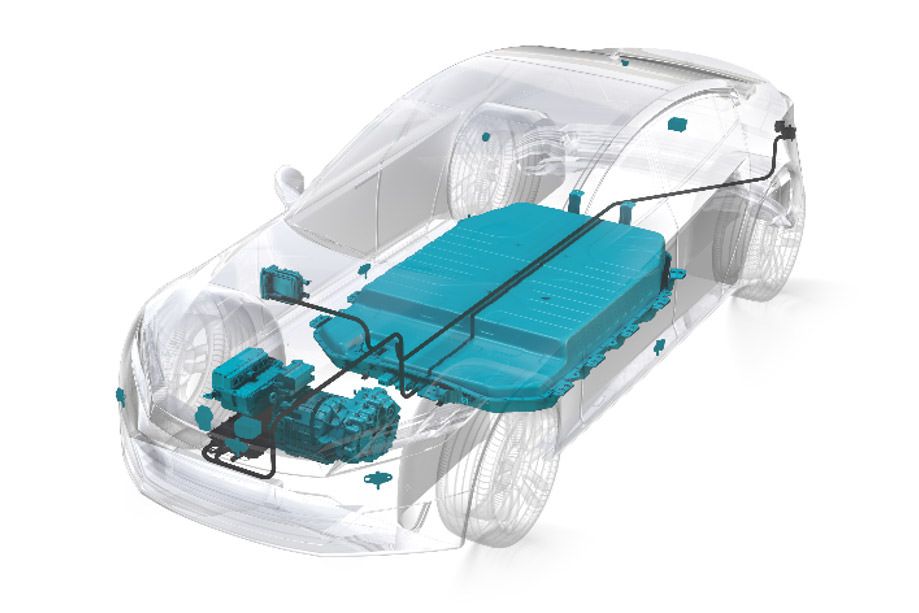

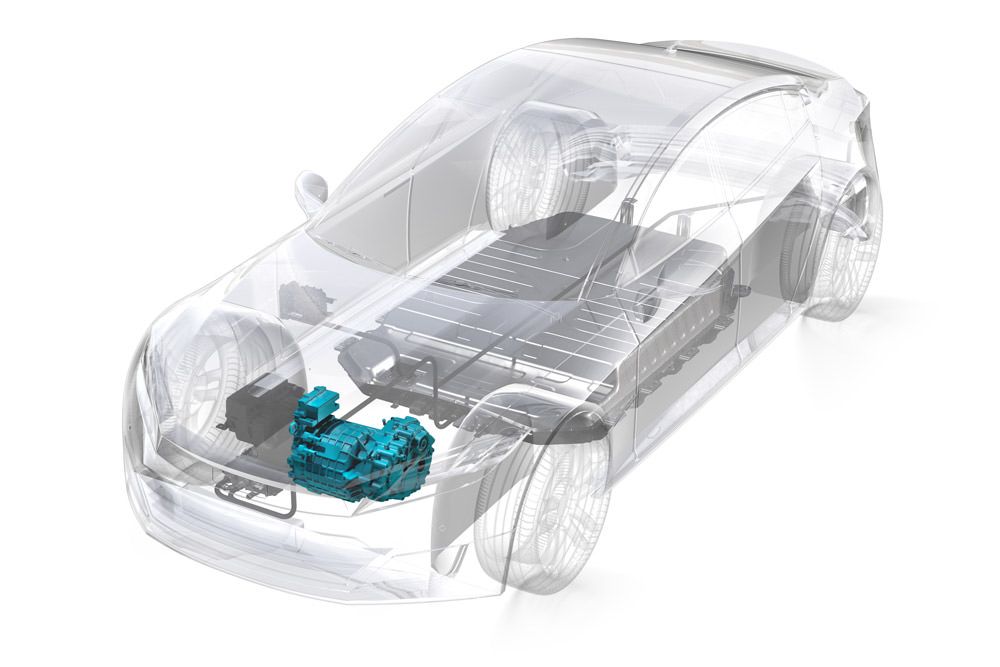

Datwyler’s range of sealings for electric vehicles with three important solutions for e-powertrains.

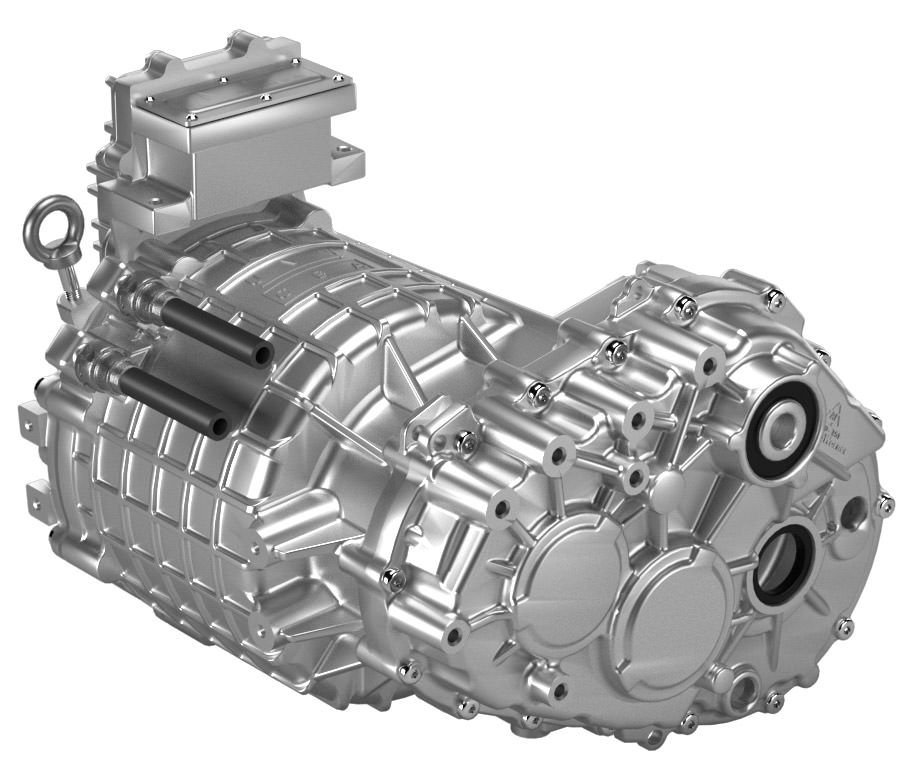

One of the biggest changes to vehicles during electrification is the simplification of the powertrain. But while the basic process of converting energy to movement may be simplified, the demands placed on individual components have increased, with high temperatures and electrical power requiring a whole new level of performance and safety.

The electrification of the powertrain requires a series of materials that offer a range of physical properties such as thermal and electrical insulation and conduction, alongside strength, durability, and long-term reliability. Datwyler has a complete portfolio of customized sealing solutions along the complete powertrain, from housings and cover gaskets to the electronic and thermal management systems, including connectors and O-rings. Using precise single and multi-component combinations of elastomers, thermoplastics, and liquid silicone rubber (LSR), our solutions provide maximum sealing efficiency, as well as high levels of protection and safety, resulting in exceptional powertrain performance.

In-house tooling

With decades of experience and our own in-house tooling center, we are experts in creating advanced high-precision tooling solutions for elastomers, thermoplastics, and liquid silicone rubber components that scale easily from prototype to full production.

Exceptional product quality

Our best-in-class molding technology, along with extensive automated testing and quality check processes, ensure all our components achieve a consistently high level of quality.

Advanced technology

We offer the full range of the latest equipment across our global network of facilities for every stage of the production process, from simulation and testing to analysis and manufacture.

Co-engineering experts

Datwyler excels in customer partnerships, working with you to develop the ideal solution to your challenge. From idea generation and simulation to testing and production, we will support you every step of the way.

Tooling is an essential part of our business. To produce complex LSR and thermoplastic parts, you need very precise molding tools, and our advanced in-house equipment makes it much easier to give our full support to customers.

Jan Ott

Head of Center of Engineering LSR and Thermoplastic

To find out more about our electrified powertrain co-engineering and manufacturing services, and how we can help develop your next sealing solution, please get in touch with us.