High quality sealing solutions for e-powertrains

Article | January 25, 2024

Find out more about Datwyler’s range of sealings for electric vehicles with three important solutions for e-powertrains.

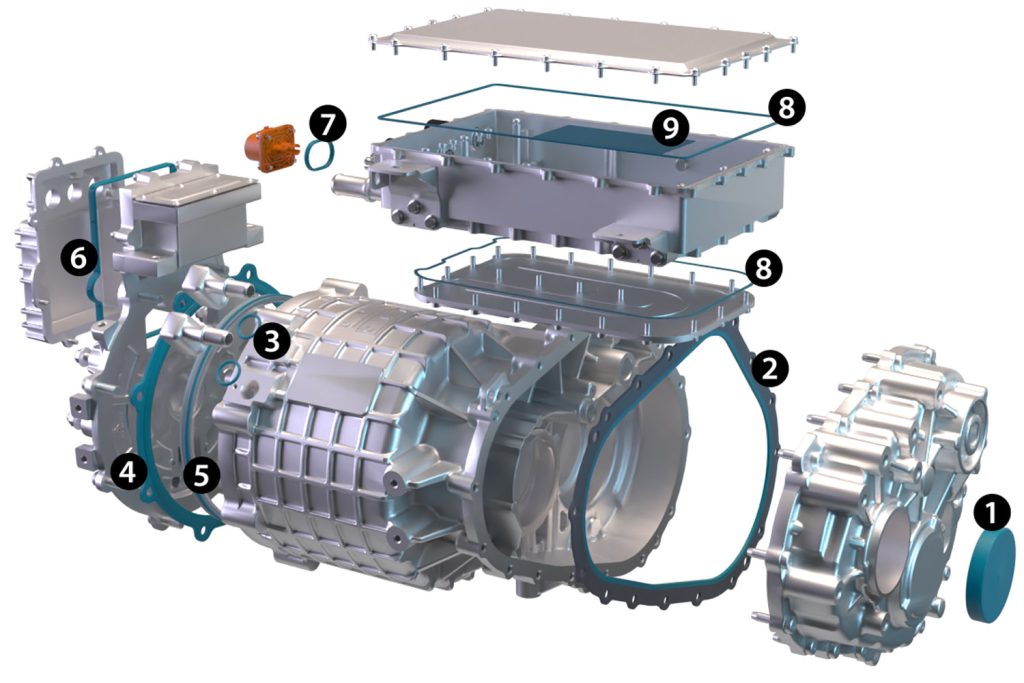

With an increasing global demand for electric vehicles (EV) and more investment in the technology involved in electrification, there is an increasing focus on the e-powertrain – the driving force of all EVs. An e-powertrain still requires a wide range of high quality system-critical sealing solutions for a broad variety of applications, each solution designed and tested to ensure it provides long-term reliability and performance.

Datwyler offers a large portfolio of products for the e-powertrain, from O-rings and connector seals to two component (2K) gaskets. These products are available in a range of geometries and materials including pure rubber and liquid silicone rubber (LSR), as well as options such as edge-bonded.

Our solution portfolio covers our customers’ complete range of requirements for the e-powertrain, providing the ideal solution for the individual application.

- Plug Seal

- Edge-bonded Gasket

- O-Ring

- Housing Gasket

- Oil Baffle

- Press-in-Place Gasket

- Connector Seal

- Inverter Housing Seal

- TIM (Thermal Interface Material)

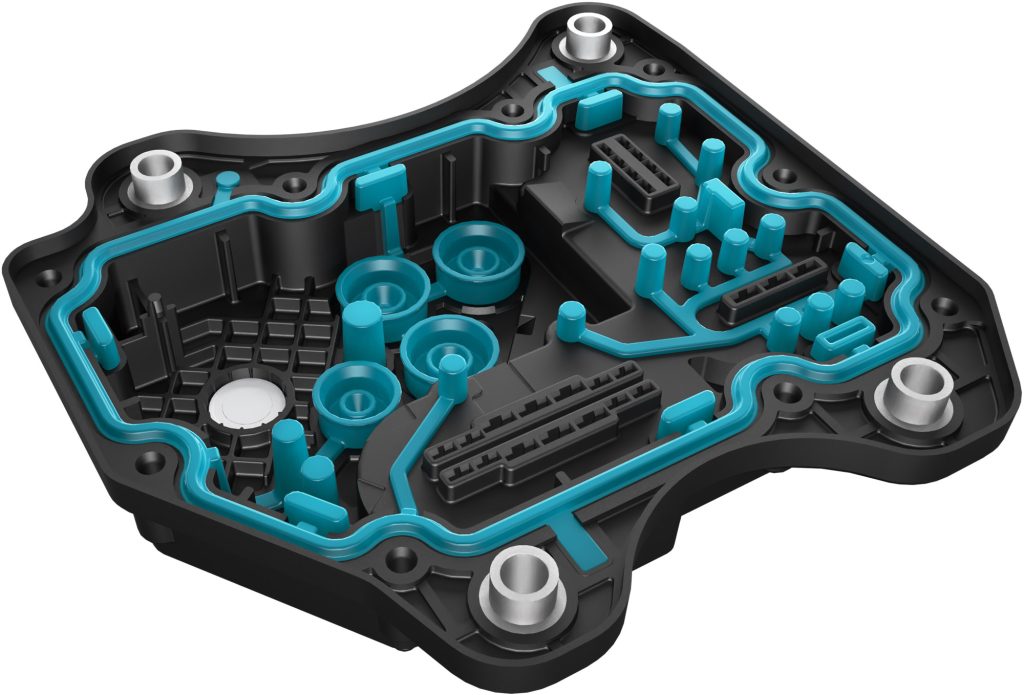

Among the many sealing solutions Datwyler offers for the e-powertrain, we will focus in this article on three specific products: the housing gasket, oil baffle and LSR 2K gasket.

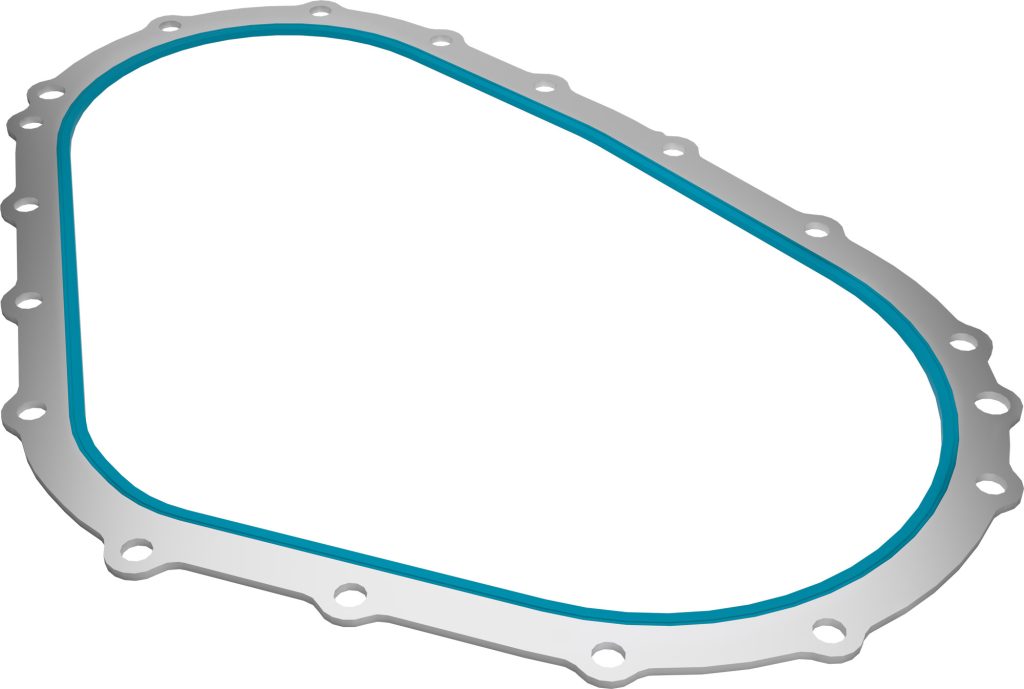

Housing gasket

The gasket is one of the most common sealing solutions in the e-powertrain, and the housing gasket is one of the most important. It has a range of purposes, from sealing the transmission to prevent the release of oil to separating sections of the upper and lower housing of the invertor to prevent contamination from external particles or liquids. Housing gaskets ensure the components continue to deliver the optimum amount of cooling and power to the vehicle.

Produced to a customer’s exact specifications, Datwyler’s range of housing gaskets include customized full-rubber gaskets, LSR 2K gaskets, and edge-bonded gaskets.

Edge-bonding involves bonding an elastomer seal to an aluminium or steel carrier, forming a robust and resilient part that offers a longer lifetime than traditional rubber gaskets.

Edge-bonded gaskets also offer an ideal solution for a compact sealing interface, where a recess for a press-in-place gasket is not possible.

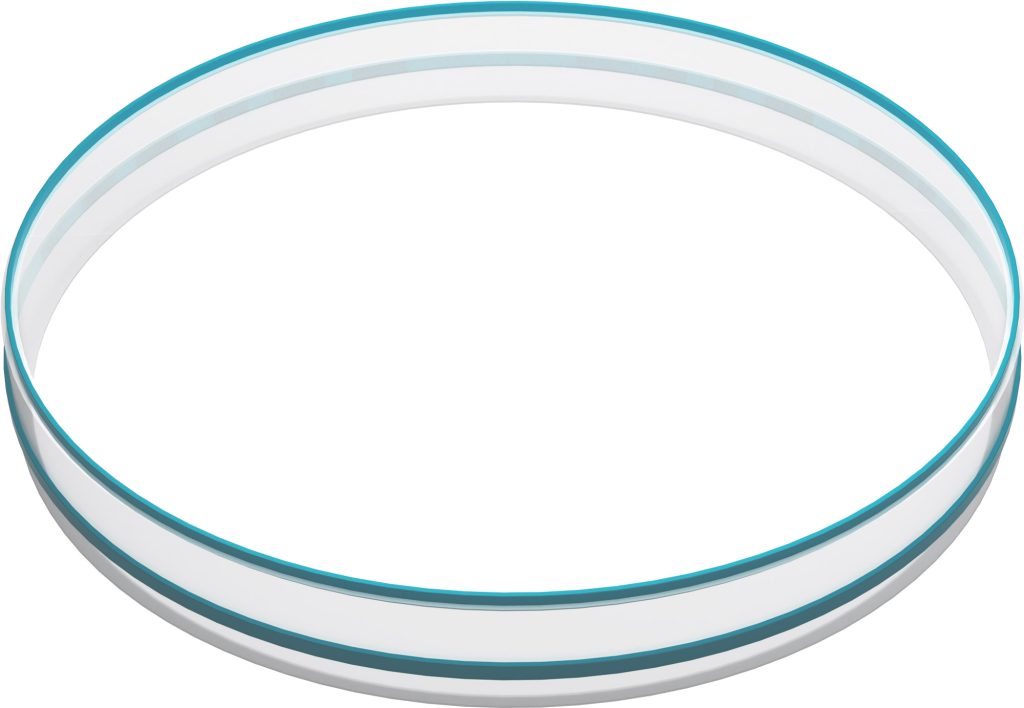

Oil baffle

The oil baffle is a key component in an e-motor, controlling the flow of oil within the powertrain.

Working together with the housing and rotor, it distributes oil through small holes in its plastic ring to increase lubrication, decrease noise, and reduce the temperature of the e-motor, optimizing the performance of the powertrain.

Inside each oil baffle there are two rubber sealing rings that enable the oil within the chamber to achieve the required pressure. These sealing rings need to be highly resistant to temperature as well as oil to provide long-term reliability.

LSR 2K

2K parts are a relatively new sealing technology that eliminates the requirement for the rubber and plastic components to be assembled. This reduces the time needed for manufacture of the e-powertrain as well as the costs and number of suppliers in the supply chain.

2K parts are a combination of plastic and rubber, which are molded together as a tightly bonded, high-precision composite.

As well as providing a cost-effective sealing solution, LSR 2K parts also have a lighter weight and are highly rigid, making assembly quicker and more accurate in automated systems to reduce the amount of potential errors.

As more time and investment is made into the development of the e-powertrain, the need for more effective and efficient sealing solutions will increase. Without the flawless performance of these system-critical sealing solutions, the e-drive is not ensured, which would lead to high costs of failure and major risks for drivers and passengers.

As a proven partner of the automotive industry and with deep knowledge and experience in elastomer technology, Datwyler will continue to innovate in this future-oriented application.

author

High-performance Components