Currently, conventional actuator systems have a complex mechanics that generate noise and vibrations, which can cause premature wear or disrupt other mechanical elements of the system. This complex and heavy construction also results in a large size which limits its integration in restricted environments. Furthermore, in the case of actuation and displacement measurement on the same side, additional sensor components are also required. The quality and thus the realistic simulation of feedback in combination with limited space available are difficult challenges for a switch. Finally, today’s conventional actuators have a high energy consumption and require maintenance, which results in high operating costs.

The last decade saw a rising interest towards alternative low-energy consumption actuation technologies and “smart materials”.

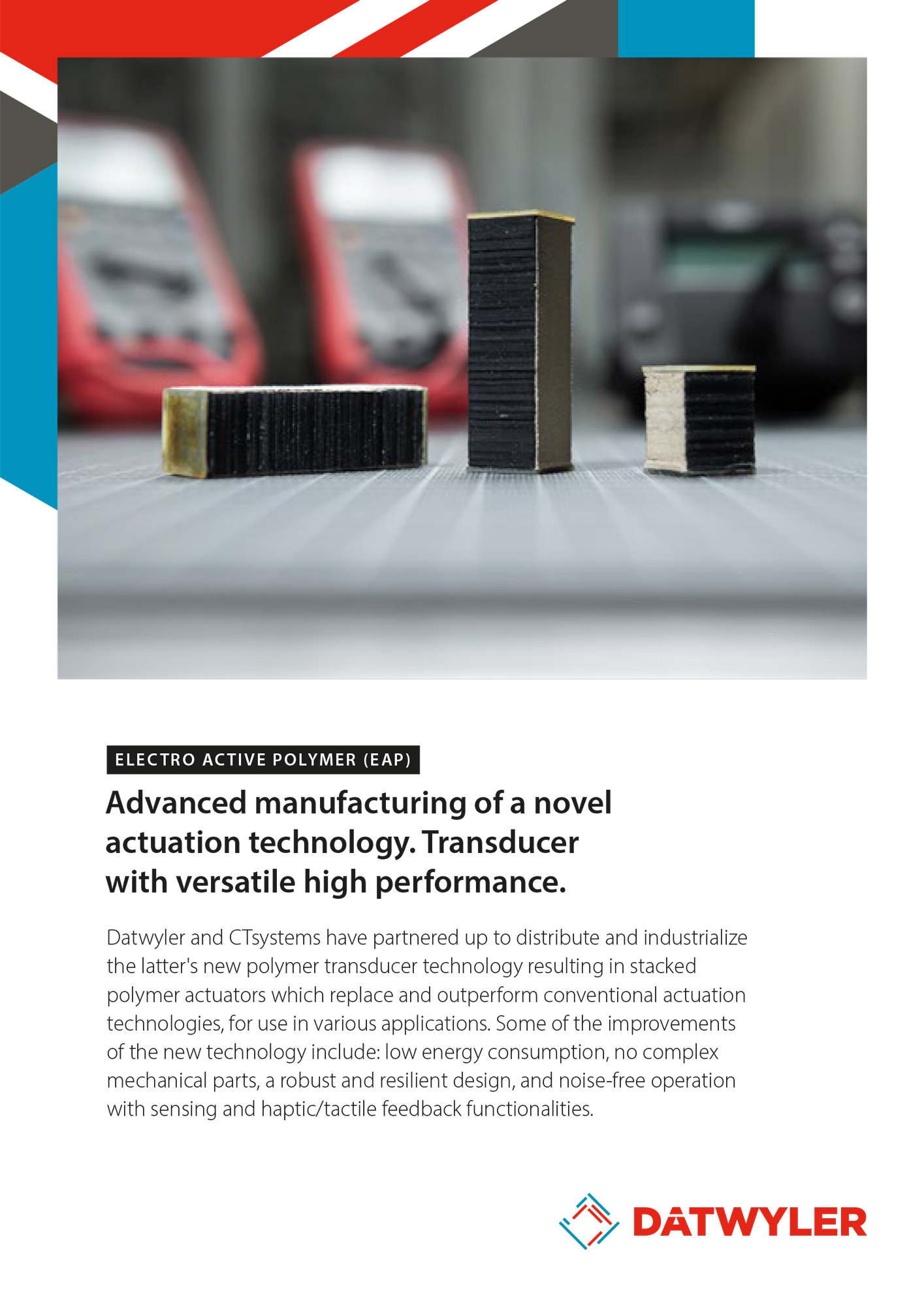

Datwyler is on the path to industrialize a new polymer transducer technology (“Electroactive Polymers” or EAPs) based on stacked polymer actuators, which was originally developed by CTsystems, a spin-off from EMPA, Switzerland. EAPs can replace and outperform conventional actuator technologies and can be used in various applications. Advantages of EAPs include low energy consumption, no additional complex mechanical parts, a robust and resilient design, noise-free operation with the possibility for energy harvesting, sensing, and haptic/tactile feedback functionalities.

A flexible solution for numerous applications.

Latest news

Solution

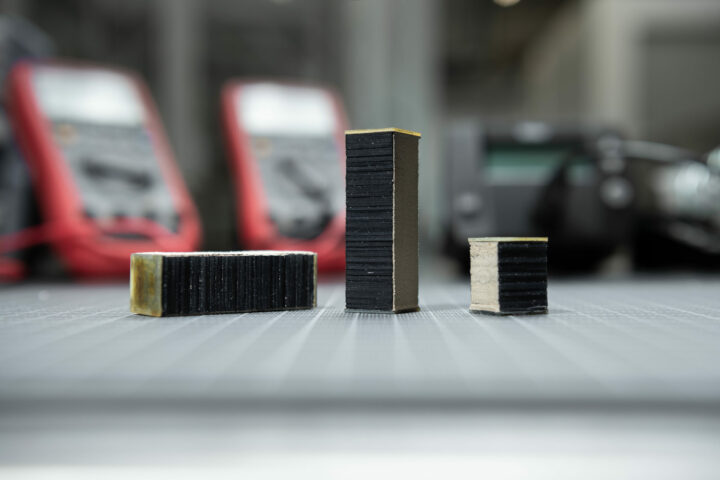

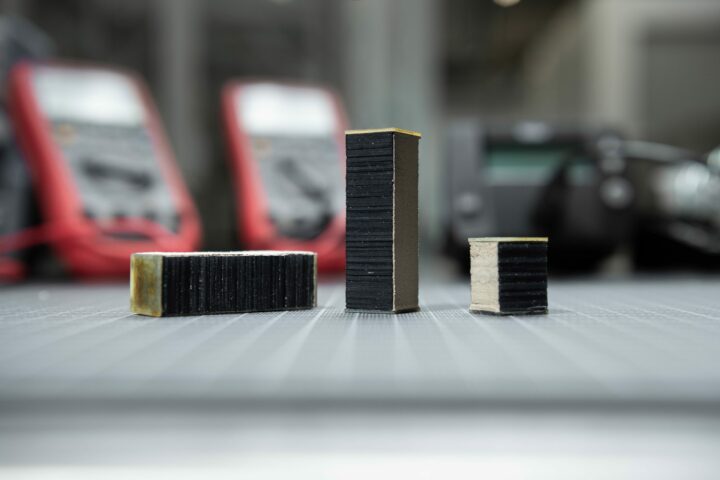

The stacked design of the new multi-layer actuator allows high contraction movement and tension force capabilities.

The particular design of the dielectric elastomer used in the actuator, is based on a series of flexible capacitors electrically connected in parallel to alternating polarities of each layer. This new arrangement makes EAP technology suitable for a wider range of potential applications.

These elastomers have the particularity of being silent and generating no vibration. In addition, this new technology directly integrates sensing functionalities (no additional sensor components) which makes the actuator more compact. These two parameters make the integration of this new solution optimal in restricted and mechanically precise systems.

The same sensing functionalities are enhanced by offering short response time, adaptable amplitude shapes and a wide frequency range. This makes its use much more interesting for haptic/tactile human machine interfaces.

Finally, the energy consumption of the new actuator is significantly lower than those of conventional actuators, which therefore reduces the operating costs of the mechanical system that integrates them.

How it works

Electro-mechanical transducer made of soft and elastic polymer.

Electrical power turns into mechanical motion by elastic deformation.

Our unique thin layer dielectric elastomer stacks allow tactile and sensitive actuation and sensing.

Reliable electrostatic working principle for multipurpose and efficient operation.

Key benefits

Position holding

Green, efficient and mobile application

with very low energy consumption (close to nothing).

Stepless proportional positioning

Light weight, solid and compact size

by voltage governed stroke.

Actuation and sensing

Cost-saving monoblock and integration with simultaneous actuation and sensing capability

allowing high versatility of operation.

Macro scale stroke

Resilient, enduring design

through low material stiffness, high insulation.

Noise free actuation

Maintenance and noise free

thanks to stroke by pure material deformation.

Low-cost device

given by processing technology driven costs.

Compact and lightweight

constituted by high energy density.

APPLICATION

EAP Pump demonstrator with adaptive fluid control

General properties

20N

Max. actuation force (dependent on stack dimensions)

10 %

Max. contraction

unter 2 ms

Actuation time (dependent on stack dimensions)

50 Hz

Actuation frequency (dependent on stack dimensions)

-40°C bis +130°C

Temperature resistance