Datwyler Production System (DPS) Model

The Datwyler Production System has been developed and is based on Datwyler’s existing company values and lean principles. Operational excellence is our ultimate goal and consists of six dimensions: Safety, Quality, Delivery, Costs, Environment, and People.

Six dimensions foster excellence

The ultimate goal of the Datwyler Production System is to achieve and maintain operational excellence and foster a lean culture. By fully taking advantage of our potential, we advance our leading global position and strengthen our competitive advantage. We strive for operational excellence in everything we do and have defined six dimensions that cover all aspects of our business.

Safety – We ensure a safe workplace

We ensure a safe workplace in all our offices and production sites worldwide.

Quality – We have no quality issues

We only deliver the highest quality and offer proven solutions. If any of our products should not meet our costumers’ expectations, we will immediately investigate the cause of this irregularity.

Delivery – We deliver as promised

We strive to avoid any surprises or unexpected difficulties. We deliver products and services as promised – all ordered products, right on time.

Costs – We have no waste in our processes

By optimizing our business and manufacturing processes as well as our operations processes, we are able to offer the best value at low costs.

Environment – We protect our environment

We are fully aware of the finite nature of our resources and our fragile ecosystem. Therefore, reducing our environmental footprint is one of our top priorities.

People – We have satisfied and empowered people

Every successful company is founded on its employees. It is our responsibility to empower them and give them what they need to excel in everything they do.

Our five fundamental elements

The Datwyler Production System consists of five fundamental elements that build a framework for our ultimate goal – to achieve and maintain operational excellence and foster a lean culture. These elements serve as orientation to all employees worldwide and give guidance when strategic decisions have to be made.

Leadership and poeple empowerment

is to give direction, inspiration, and power to everyone to achieve operational excellence. At Datwyler, we facilitate the continued learning of our employees and are continuously transforming ourselves. Our roles and responsibilities are clearly defined, and our targets and actions are aligned with a long-term planning perspective. We create transparency, and we lead by example.

Process stability

is to produce consistent results with predictable performance and quality over time. Therefore, we create standard tasks and processes, keep our workplaces safe and efficient, and secure required resources. We pass on only good quality.

Flow

is to streamline our business and manufacturing processes. This way, we keep things simple, synchronize production, create a continuous flow of items, products and information within a process, and shorten the required production time.

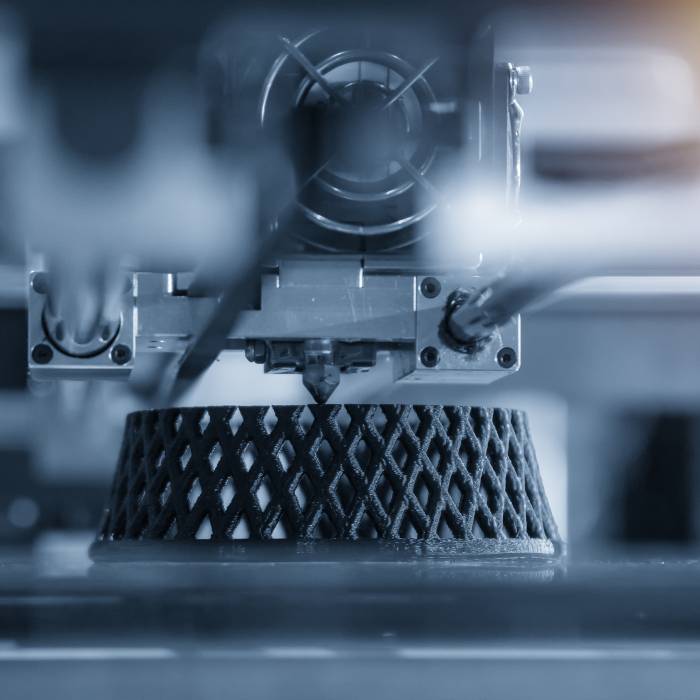

Design for future

is to ensure that everything we invest in improves our current condition and allows us to outperform our competitors. This means that we create efficient factory designs and layouts, provide reliable and future-proof technology and manufacturing processes, while fostering cooperation with employees from different functions and across different sites – all working towards a common goal.

Continious improvement

is the driving force behind our success. Our standard improvement method allows us to learn from each other to enhance our products, services, and processes. This will build a culture of ongoing improvement, where everyone, everywhere changes for the better every single day.

State-of-the-art facilities.

All facilities are geared towards optimal manufacturing processes for each respective product group. In this respect, the FirstLine® facility in Belgium is specially designed to manufacture pharmaceutical rubber components in a fully integrated GMP environment using innovative automated processes, and conforming to the highest industry standards. Its use of innovative energy saving techniques means that this facility is also designed according to the latest environmental sustainability standards.

Equally advanced is our fully automated facility in Schattdorf, where we manufacture consumer goods. This facility is built on proprietary technology, with the entirely automated production process aimed at achieving perfectly manufactured parts at the rate of tens of millions per day.

A zero-defect philosophy.

We begin with the approach of quality by design, whereby the processes and products are designed according to a zero defect philosophy, and employing automated processes as far as possible. If you require, we can combine this process with proprietary inspection technology that guarantees 100% inspection of each individual part in your application.

As early as 1995 we were breaking ground with our first fully automated camera inspection system for rubber products for the Japanese medical market. Since then, we have continuously built on this experience, and are currently using our fourth generation of camera systems in a class 100 clean room.

It is thanks to this combination of exceptionally consistent and robust automated processes with detailed inspection tools that we can supply our customers with billions of parts per year, with each and every one of them meeting the requirements of a high quality product that you have come to expect.

Large-scale production.

Thanks to our extensive experience of a whole variety of production technologies, Datwyler has developed in-house processes to ensure that we can manufacture billions of products both economically and with zero defect capability. This has been made possible by building an extensive portfolio of technological expertise both in-house and in close cooperation with highly competent technological partners over many decades. Certain high quality products are manufactured at a rate that exceeds 25 million parts per day, with each individual part meeting the strict quality standards you expect.

Datwyler Sealing Solutions can offer you this unique proposition of top-quality components in the fields of pharmaceuticals, foodstuffs, automotive, civil engineering and other industries worldwide, with contingency and risk mitigation integral to our agenda. For many customers we are the unique supplier of such solutions.