Transportation & Electronics

2025 in Review: Engineering Reliability at Scale and What’s Next for 2026

Article | December 23, 2025

A year of rapid electrification, rising quality demands and industrial scale-up. Discover the key trends shaping mobility, battery systems and how Datwyler is driving reliability into 2026.

From Acceleration to Industrialization

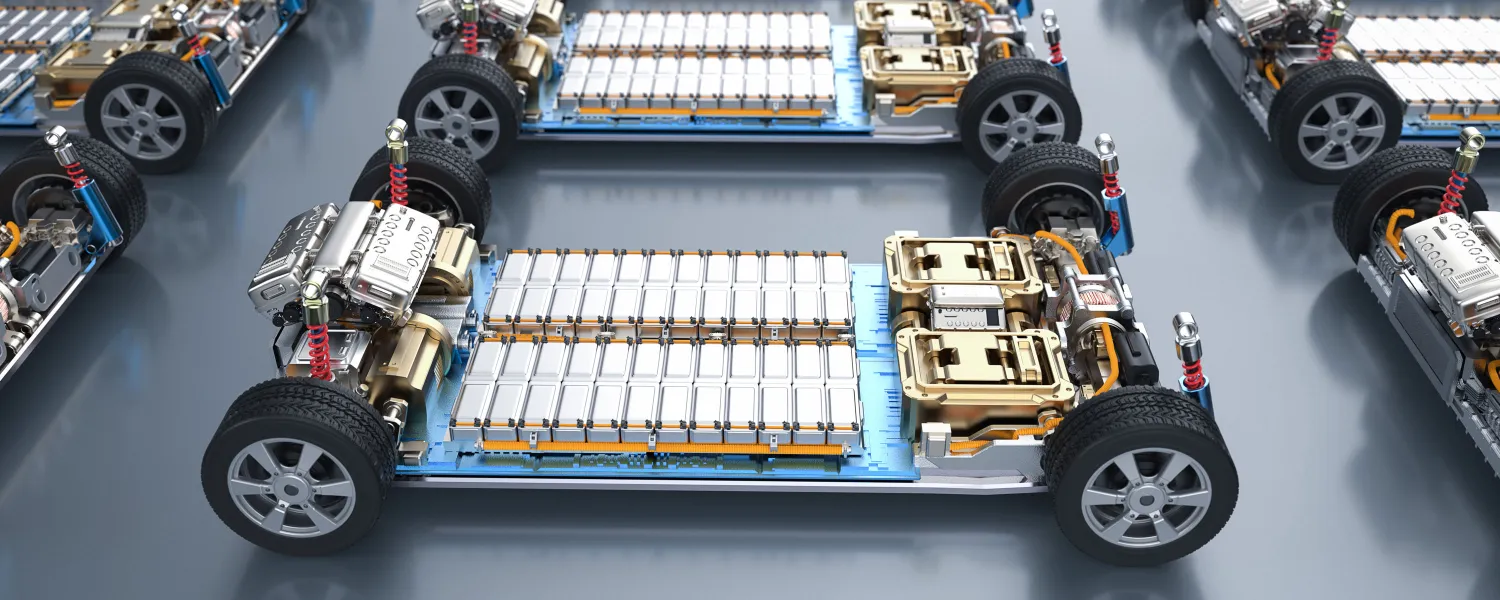

As 2025 draws to a close, the e-mobility sector has crossed a decisive threshold: mass industrialization. Global EV sales surpassed 22 million units this year, marking a 25 percent increase over 2024. Electrification has evolved from demonstration programs into a fully embedded part of global automotive production.

The past year was not only about growth but about engineering refinement, regulatory enforcement, and supply-chain maturity. Battery and e-powertrain systems were designed and validated under higher voltages, denser packaging, and tighter tolerance windows than ever before. As OEMs and Tier-1 suppliers scaled up, the hidden enablers of reliability – advanced sealing and material solutions – proved fundamental in maintaining performance, safety, and manufacturability.

2025’s Defining Technical Shifts

Three key transitions shaped 2025’s engineering landscape. First, architecture consolidation accelerated. Structural and cell-to-pack battery designs became the new normal, improving energy density and cost efficiency while introducing more demanding sealing geometries and smaller compression zones. This elevated the importance of Datwyler’s priority battery portfolio, including battery cell seal, BMS grommet, ring seals, single wire and cable seals, busbar seals, etc. All central to achieving consistent pack integrity and electrical isolation.

Second, the full implementation of the European Battery Regulation (EU 2023/1542) set new benchmarks for thermal propagation safety, venting behaviour, and sustainability. Validation protocols now require documented stability and recyclability at the material level. Datwyler’s in-house compounding and analytical capabilities allowed OEM partners to meet these requirements through fully characterised material datasets and regulatory-compliant traceability. Fire-retardant materials for battery systems, currently in development, further strengthen readiness for upcoming safety expectations.

Finally, chemical diversity expanded. The year saw the first industrial deployment of sodium-ion and early-stage solid-state concepts. These chemistries introduced new electrolytes and immersion fluids, requiring updated compatibility across sealing materials. Datwyler addressed this through customised formulations optimised for long-term mechanical elasticity, media resistance, and thermal endurance.

The Unseen Work Behind System Safety

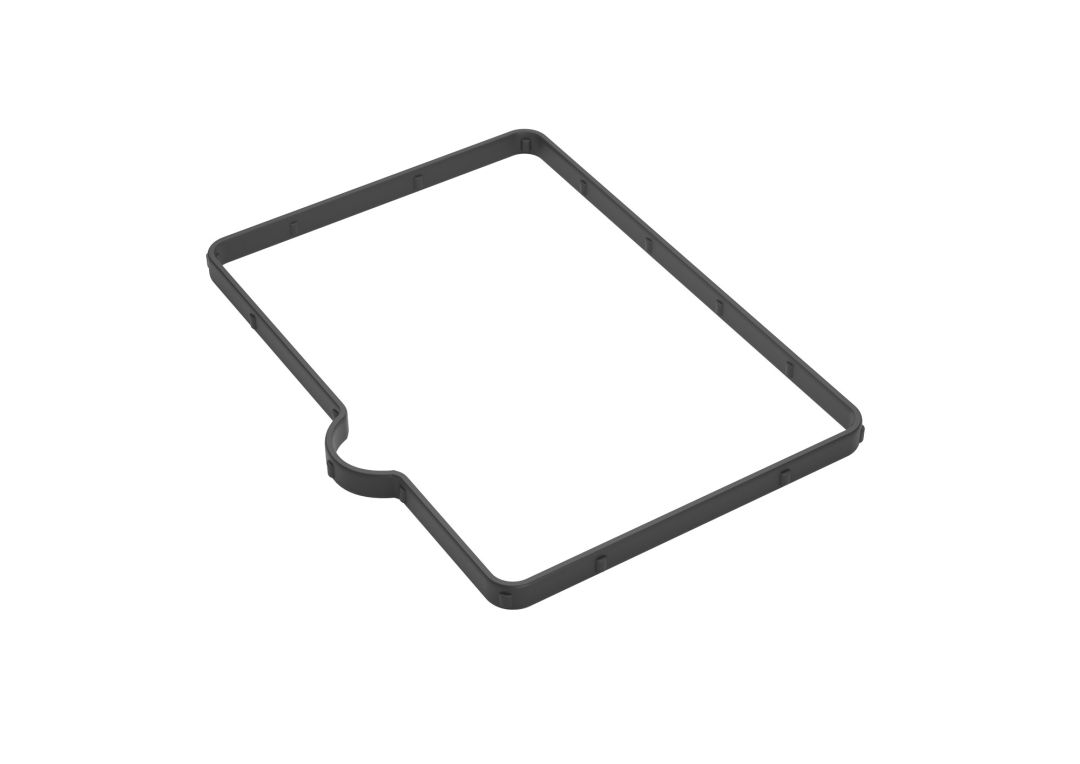

Beneath every major EV launch of 2025, sealing technology played a silent but indispensable role. In battery systems, Datwyler’s multifunctional gaskets delivered IP6K9K protection while integrating venting and pressure management functions. Busbar seals, BMS grommets and cable seals ensured reliable electrical interconnections even within densely packaged architectures.

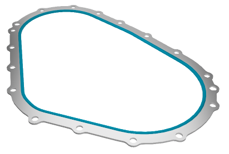

Within e-powertrains, Datwyler’s updated mobility-focused portfolio provided solutions aligned to emerging requirements. Inverter housing gaskets, press-in-place gaskets for e-powertrain housings and covers, overmolded plug seals, connector seals, EMI gaskets, and oil baffles – all highlighted in the mobility product focus – ensured reliable operation under fluctuating temperatures, differential pressures, and high vibration.

Hydrogen and fuel-cell systems also advanced, particularly in heavy-duty mobility. Datwyler’s hydrogen-ready components, including sealing discs, bipolar plates and high-purity O-rings, delivered stability across hydrogen permeation, temperature cycling, and chemical exposure.