Cutting-edge solutions for green hydrogen production

Hydrogen Production

Article | August 21, 2024

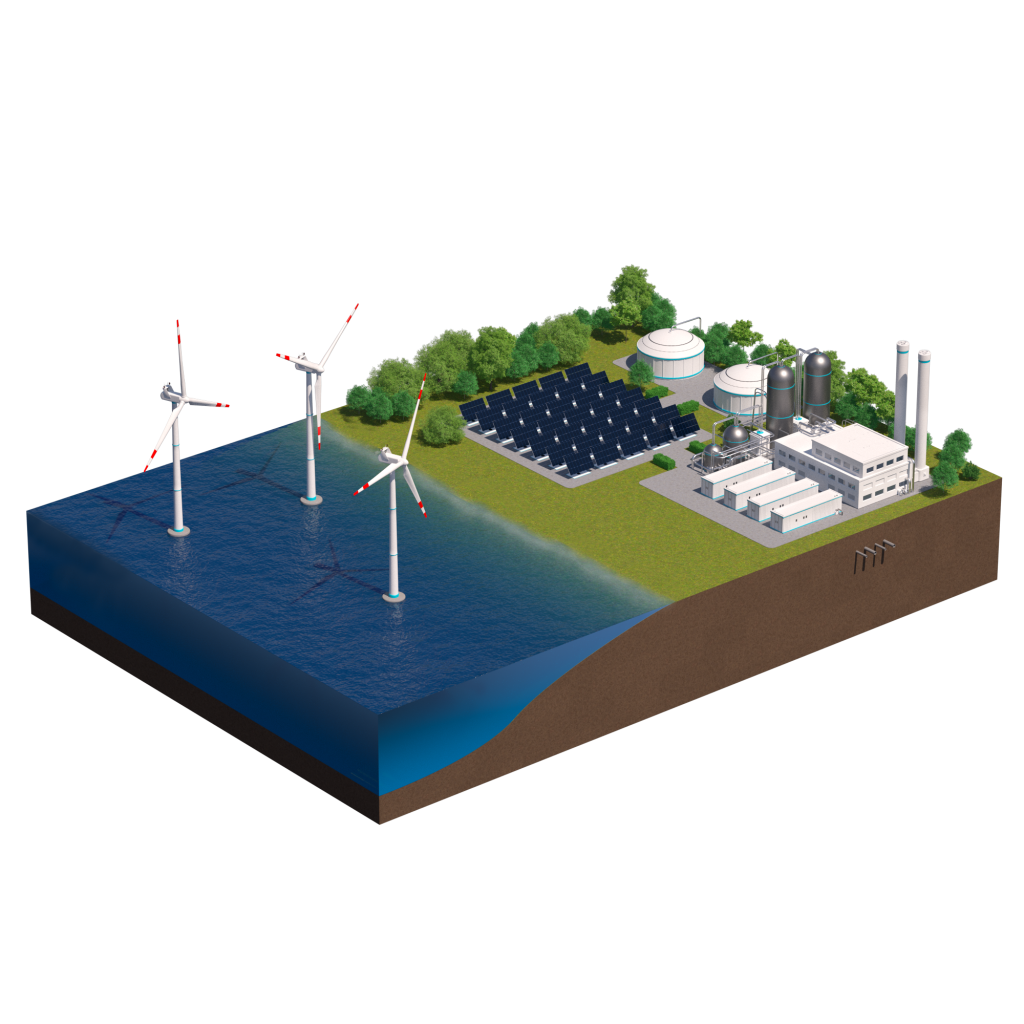

As the world pivots towards sustainable energy systems, green hydrogen is rapidly becoming a cornerstone of future energy strategies. Its potential spans the entire value chain, from hydrogen production, storage and transportation to end-use applications, presenting a multitude of opportunities for reducing carbon footprints and enhancing energy security.

Electrolysis

H₂ purification

Compression

Pumps

Storage tanks

Flow control

Pipelines

Transporation

Heavy duty machines

Power generation

Domestic heat

However, the transition to a hydrogen-based economy is not without its challenges. One of the critical hurdles is the need for reliable and efficient sealing solutions for electrolyzers, fuel cells and other hydrogen systems. These components must withstand harsh operating conditions, including high pressures, temperatures, and chemical reactions. As the industry shifts from manual production to high-volume, semi-automated, or fully automated manufacturing, the demand for advanced sealing solutions becomes even more pressing.

Sealing solutions are paramount in hydrogen systems due to hydrogen’s unique properties. As the smallest and lightest molecule, hydrogen can easily permeate through materials, posing significant challenges in containment and transport.

At the same time, their performance can be compromised by exposure to high-pressure hydrogen, leading to issues such as swelling, leaking or rapid gas decompression.

Leveraging decades of expertise in material science, solution design and operational excellence, Datwyler provides a range of high-performance sealing solutions tailored to meet the specific and demanding requirements of hydrogen systems.

Our product portfolio for hydrogen applications includes overmolded seals designed specifically for bi-polar plates, ensuring a precise fit and reliable sealing performance. Additionally, Datwyler provides a wide range of seals engineered for auxiliary systems, guaranteeing leak-free operation and optimal system efficiency.

With a commitment to innovation and quality, Datwyler is a trusted partner for customers seeking reliable sealing solutions for their hydrogen applications along the entire value chain.

Sven Gisler

Head of Innovation and Business Development

Datwyler Business Unit