New Mobility: electrification requires simulation

Article | March 22, 2022

When developing components and parts for new mobility applications, manufacturers often face similar difficulties. The problem of searching for correct and applicable material models in order to obtain optimal calculation results is a topic that equally concerns all those working in the field of simulations.

Especially in the case of rubber materials, we often observe that companies use over-simplified models to save time and effort. Sometimes it is the case that temperature effects on part design and layout are neglected or underestimated, that creep tendency of the components of the surrounding installation space are not properly checked, or that tolerance situations or the problems that can arise during assembly are overlooked.

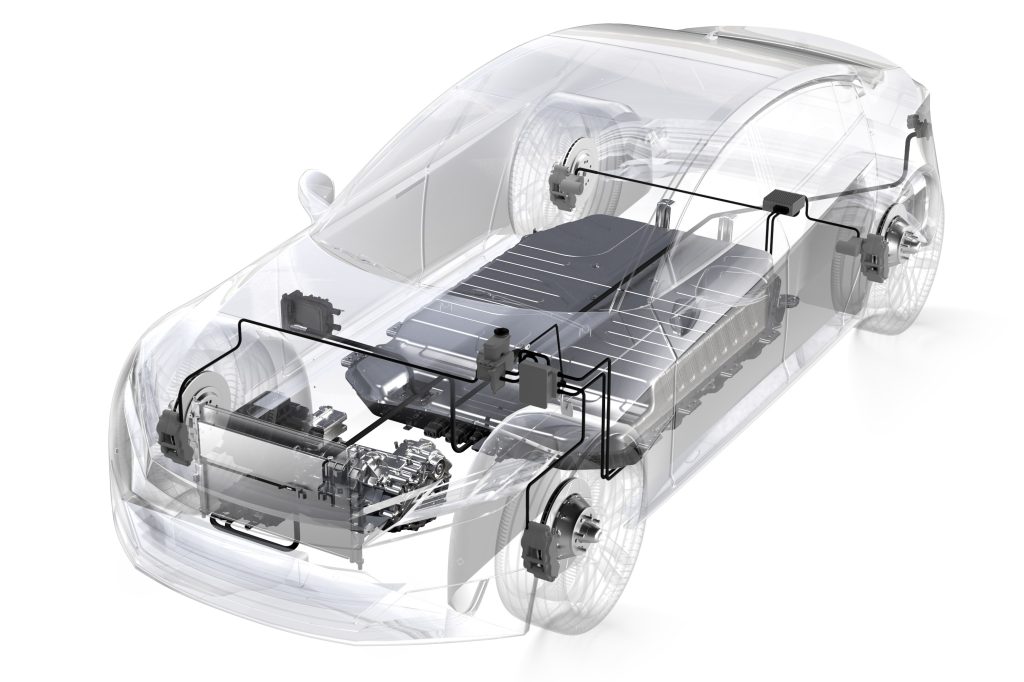

It is not surprising, perhaps, that these occurrences are commonplace. The race to electrification is gathering rapid momentum, representing as it does the automotive industry’s greatest hope for the future. Reduced dependence on fossil fuels, lower greenhouse gas emissions, and overall greener and more economical travel are all benefits, however, the electrification of transportation is a very complex process, and the development of an electric vehicle is very different from the development of a conventional vehicle.

Electrification poses many challenges

Whereas engineers developing the internal combustion engine had about a century to perfect the technology, engineers working on electrification are now being asked not only to match the performance of conventional vehicles within a decade, but to exceed it. Electric vehicle engineers must integrate both the battery together with the electric drive into the vehicle, and for us as a supplier this has implications in terms of our product development and therefore on our simulation process as an integrated part of product development.

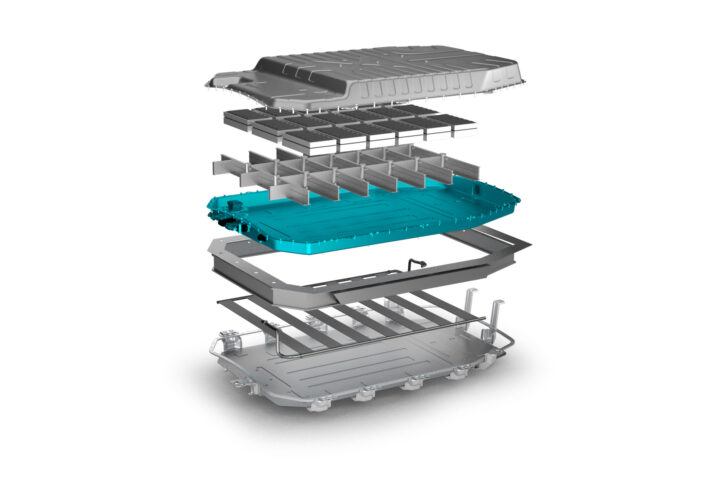

Electrification and the increased use of electronic components present many new challenges. Issues such as heat transfer and thermal conductivity, fluid-structure interaction, multi-component parts, integration of different functionalities within the same design, application of fire-retardant materials, electrical conductivity, electromagnetic shielding, integrated sensors, novel actuator systems – the list goes on and on. Then we have many new topics directly related to energy storage and generation, such as sealing, thermal stability and issues around safety and protection of battery systems, as well as sealing, separation and insulation components for fuel cell systems.

Materials for new mobility applications

Datwyler is taking a proactive approach on all fronts. For example, a recent expansion of in-house capabilities focuses on Electrically and Thermally Conductive and Electromagnetic Interference (EMI) Shielding Materials (ETEMI). Project ETEMI was launched in 2020 with a material development scope covering conventional elastomers, liquid silicon rubber (LSR) and thermoplastics.

The aim is to ensure that customers diversifying towards hybrid and battery electric vehicles are able to realize the full potential of system critical sealing components with enhanced functionality – such as sensing seal integrity or keeping electrical charge locally in a battery gasket.

Sustainability is of increasing importance

Sustainability requirements are also playing an increasingly important role – such as in the use of new bio-based materials and weight reduction issues. Sealing elements are typically small, so the impact is typically not that high, but we still need to solve problems that arise when metals are replaced by thermoplastics, for example.

Simulation makes an invaluable contribution to solving all of the aforementioned challenges and a great many more, helping to optimize the requisite components to achieve the best possible performance of the overall system. The key is to partner with a specialist simulation partner such as Datwyler at an early stage in the development process, as then it is possible to optimize from the outset and to potentially save a great deal of time and investment – bringing product to market faster and to the highest possible levels of both quality and compliance.

SIMULATION EXPERTISE

Datwyler holds simulation expertise in three core areas:

Product Development

We undertake static and dynamic non-linear structural mechanics simulations, static and transient thermal simulations, electrical simulations and multi physics simulations that combine these different disciplines within one model to ensure the simulation is as close as possible to the reality.

Process Development

Besides product functionality, we use simulations of our injection molding processes (rubber, liquid silicon rubber, thermoplastics, and multi-component) to design our molding tools and optimize our molding processes in order to produce parts with the highest quality. We are currently exploring the simulation of compression molding processes, stamping processes of rubber parts, extrusion processes, and deep drawing processes.

Testing & Modeling

An important topic in simulation is materials testing and modeling. Since we manufacture all elastomer materials ourselves, including electrically and thermally conductive and electromagnetic interference shielding materials, we have put a lot of effort into characterizing all the properties we need for simulation as accurately as possible and describing them with mathematical models. The combination with simulations allows us to create the most suitable material models for the loads that occur in each case. In the field of material testing and modeling, we are leaders in our industry segment. This material knowledge also benefits our customers – many perform simulations themselves and therefore rely on material models that we can provide them with.

Example of a Datwyler simulation project on optimizing the design of a housing seal for an electrification application.

Reduced mounting force

Introduction of groovesReduced creep tendency of the thermoplastic housing

Introduction of groovesIncreased seal integrity and long-term peformance

Introduction of groovesImproved compensation of design tolerances

Increased seal heightIncreased seal integrity

Increased seal height

At Datwyler, simulation is not the responsibility of the engineering departments of the individual business areas and business units, but of the global Technology & Innovation function.

As a result, we are in close contact and exchange with our research colleagues in Materials and Surface Technologies, our colleagues in Advanced Technologies who deal with innovations, and our colleagues from Automation, Digitalization, and Industrialization. This collaborative approach enables customers to benefit from the company’s deep knowledge and expertise as the industry continues its path towards electrification as standard, and the implementation of simulation as a global function is a clear statement of the exceptional importance Datwyler puts on digital product and process development.

author

Dr. Rudolf Randler

Head of Engineering

Innovation & Design