Battery Systems

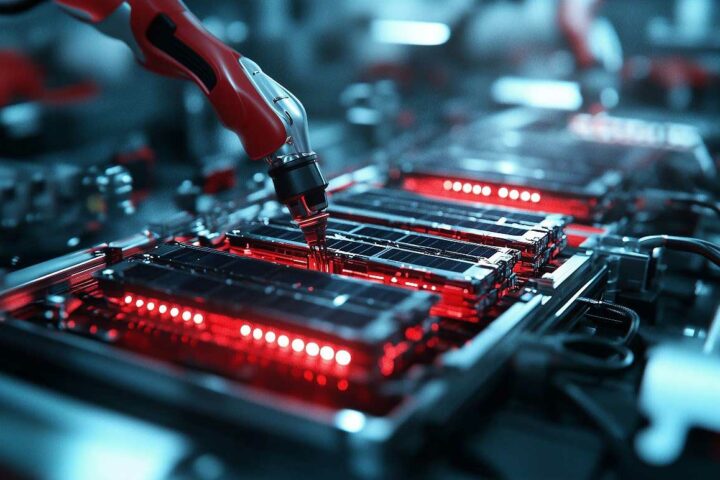

Safe and effective protection

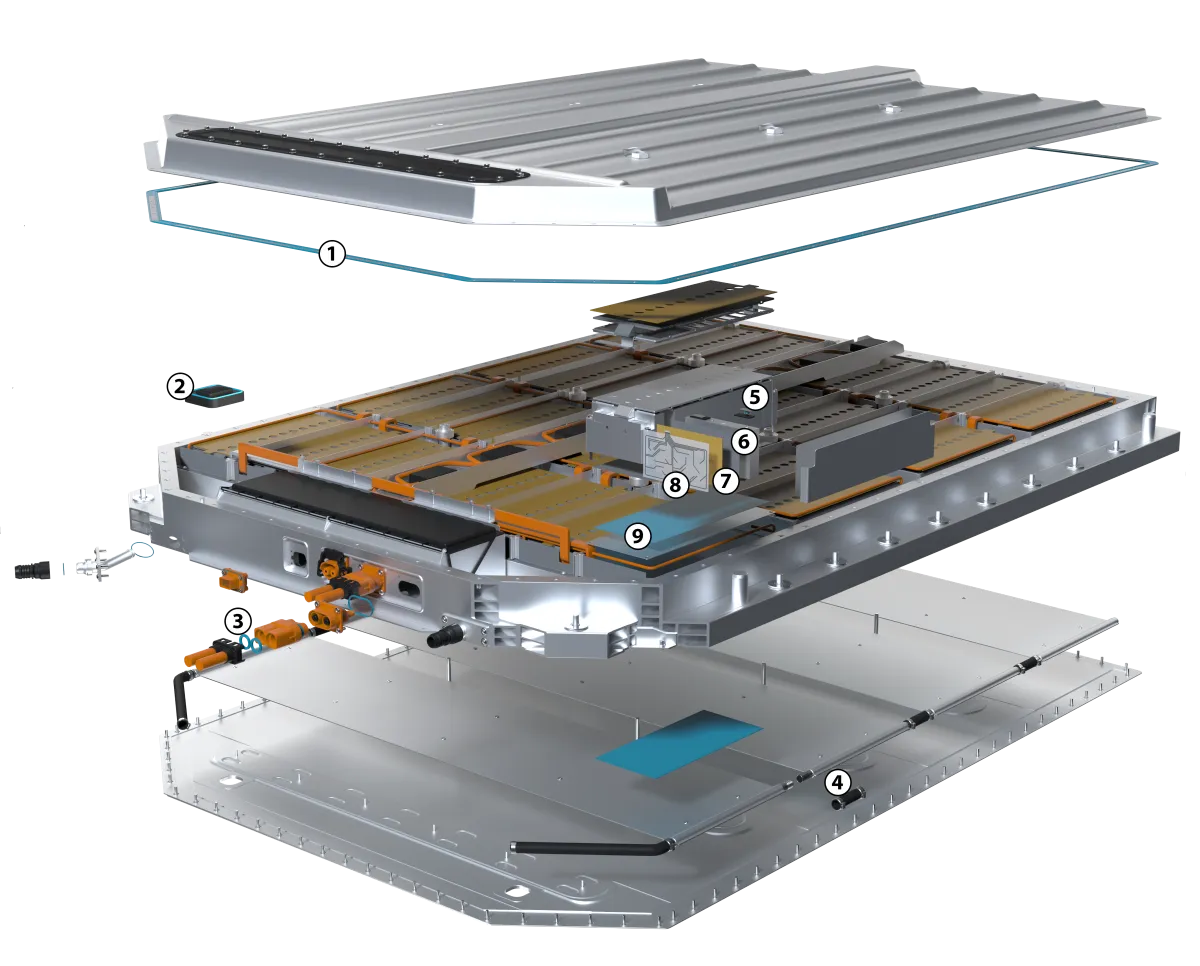

Whether it’s for lithium-ion, sodium-ion, or hydrogen fuel cells, Datwyler produces a range of elastomer-based seals and thermal conductive components that boost performance and safety in the mobility sector. From critical seals for battery packs, modules, and cells to thermal conductive components for battery thermal management, we design, develop, and produce high quality products customized to our customers’ specific requirements.

Battery Explosion

Applications

As the electrification trend continues in the mobility area, the capacity of batteries with a high safety level for electric vehicles will increase. While this will bring vital benefits such as improved range and reliability, the large thermal load placed on the battery will intensify the requirement for safety.

Through effective protection and thermal management, our range of battery seals, foldable gaskets, and thermal conductive components guard against thermal runaway without compromising function or performance.

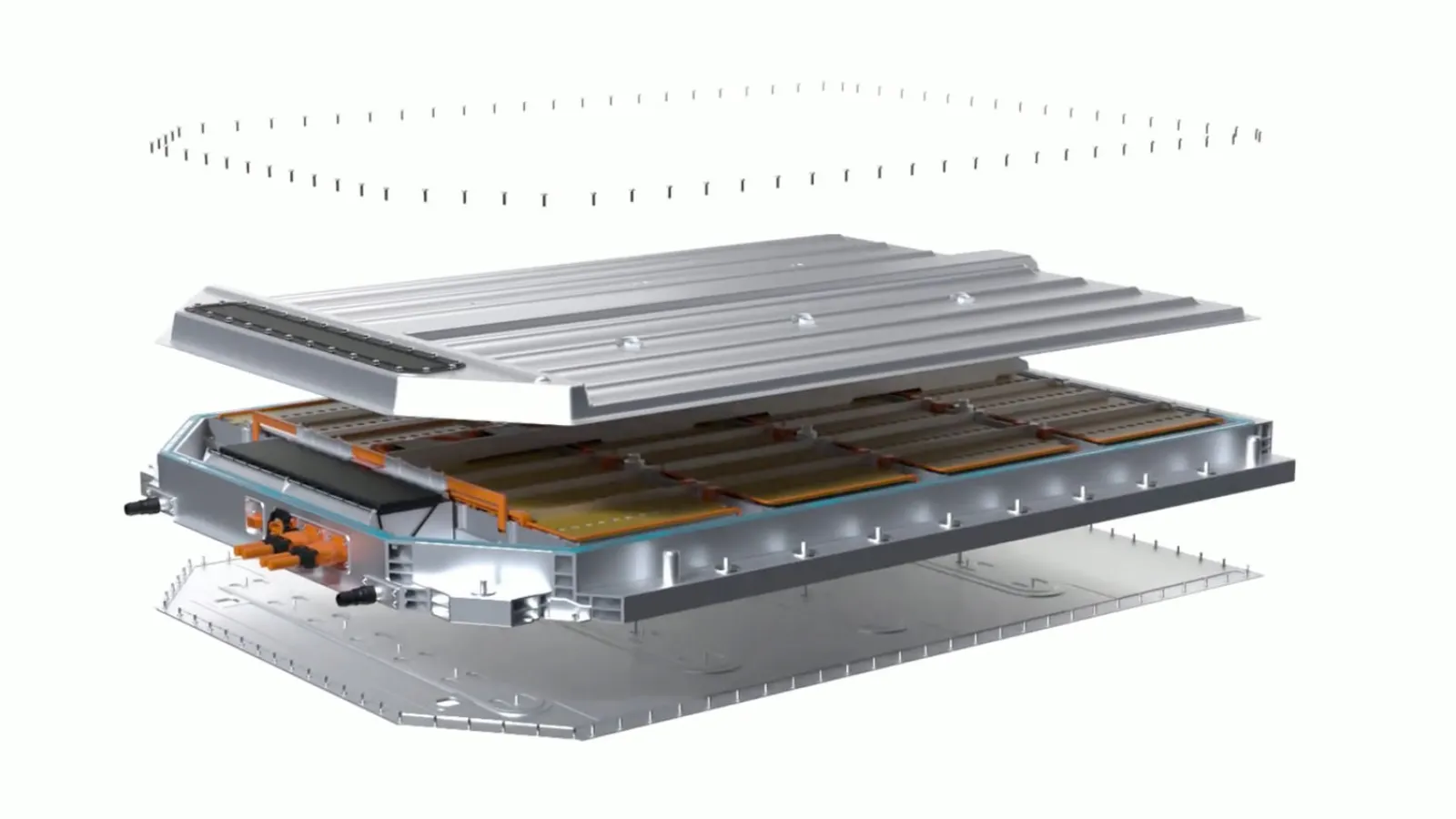

- Battery pack seal (foldable and full elastomer gasket)

- Safety valve seal

- Electrical connector seals

- Cooling plate connector seals

- Battery cell seals

- Compression pad

- Thermal propagation protection sheets

- Cell monitoring sensor

- Thermal interface material

Datwyler advantages

- Broad portfolio

At Datwyler, we pride ourselves on our wide product range, producing millions of elastomer and polymer seals, as well as multi-components and elastomer-based thermal parts for vehicle batteries of all shapes and sizes. - In-house simulation and co-engineering

Datwyler’s products for batteries go through a rigorous testing process using advanced simulation and in-house testing equipment to achieve optimum performance. Assessing how our components behave using our own data gives us a deep understanding of performance and lifetime, while customer co-engineering projects provide a customized solution. - Safe, qualified and high standard

Our number one priority is offering a series of seals and thermal components that contribute to battery safety. Our components comply with all relevant quality and performance standards. - Future-ready materials

Datwyler makes a significant investment in research and development, and is constantly working on advanced materials and solutions to accelerate our partners’ transition to carbon-neutral mobility. We have an extensive portfolio of compounds for direct immersion cooling, fire retarding, and EMI shielding.

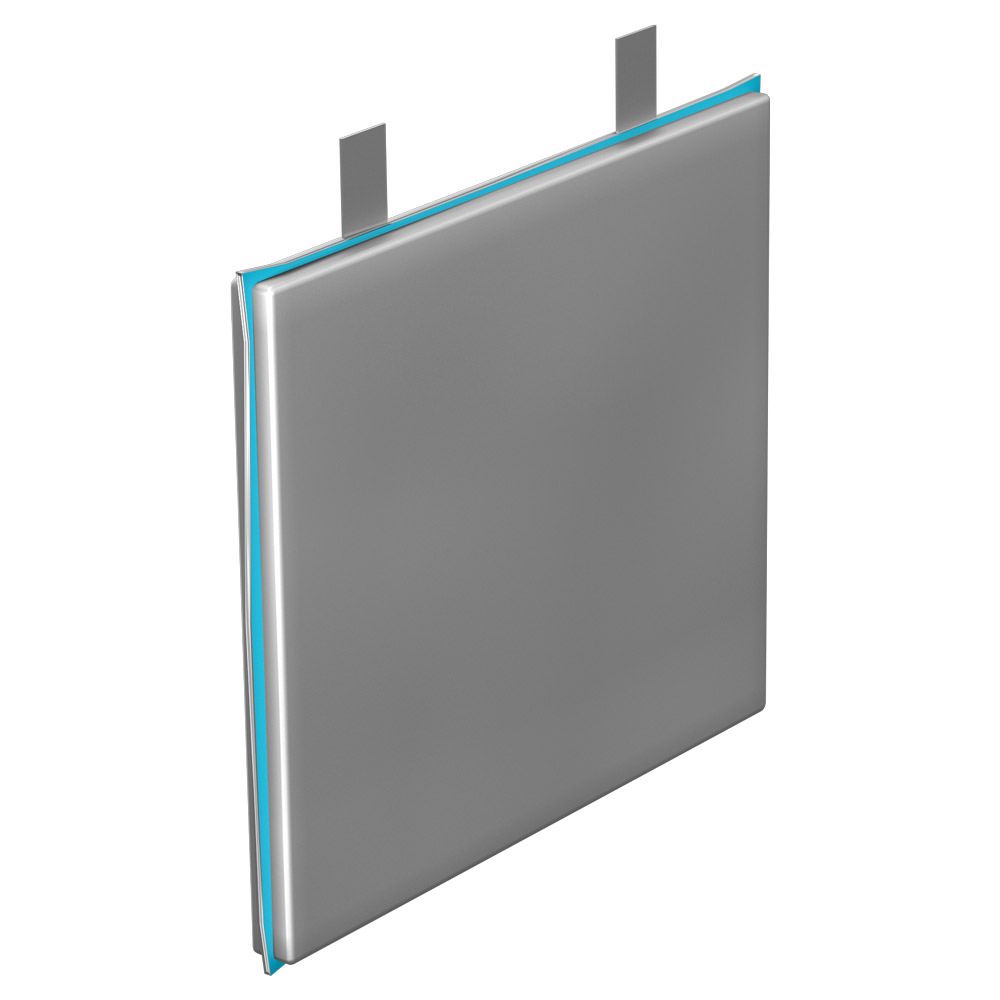

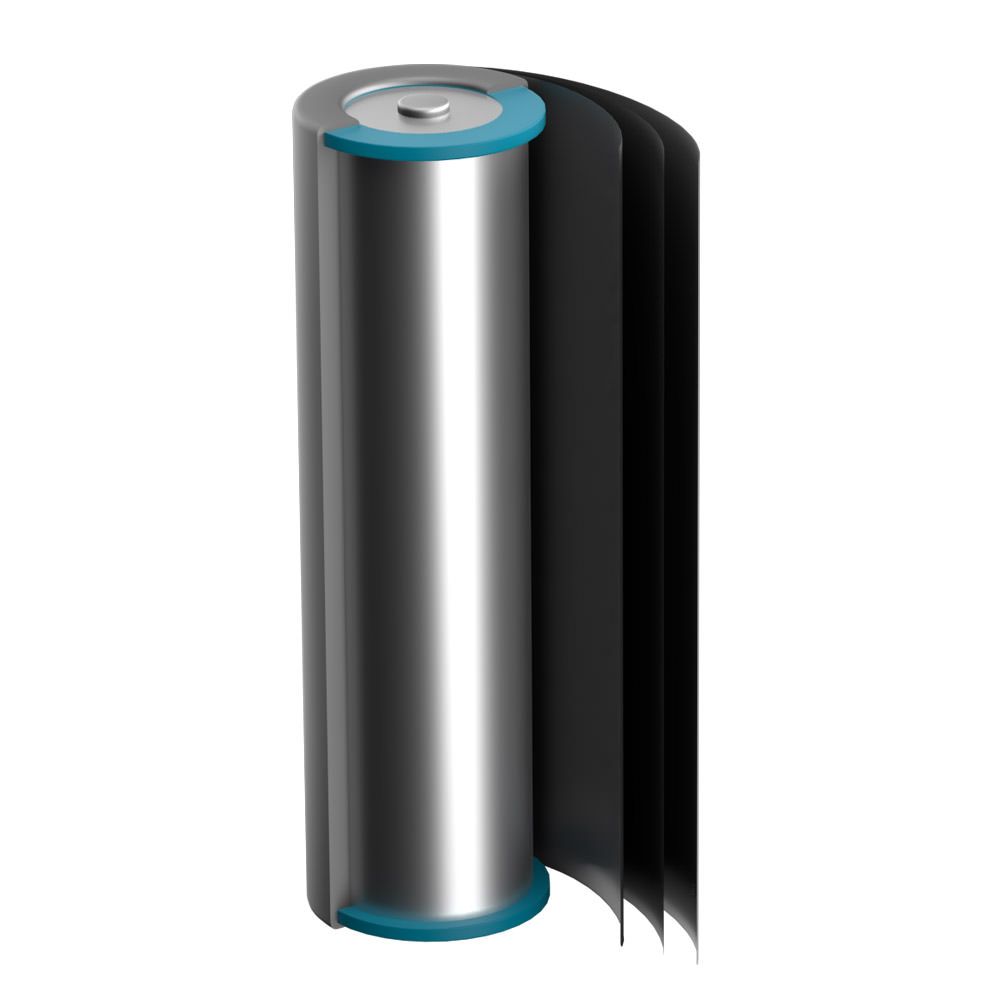

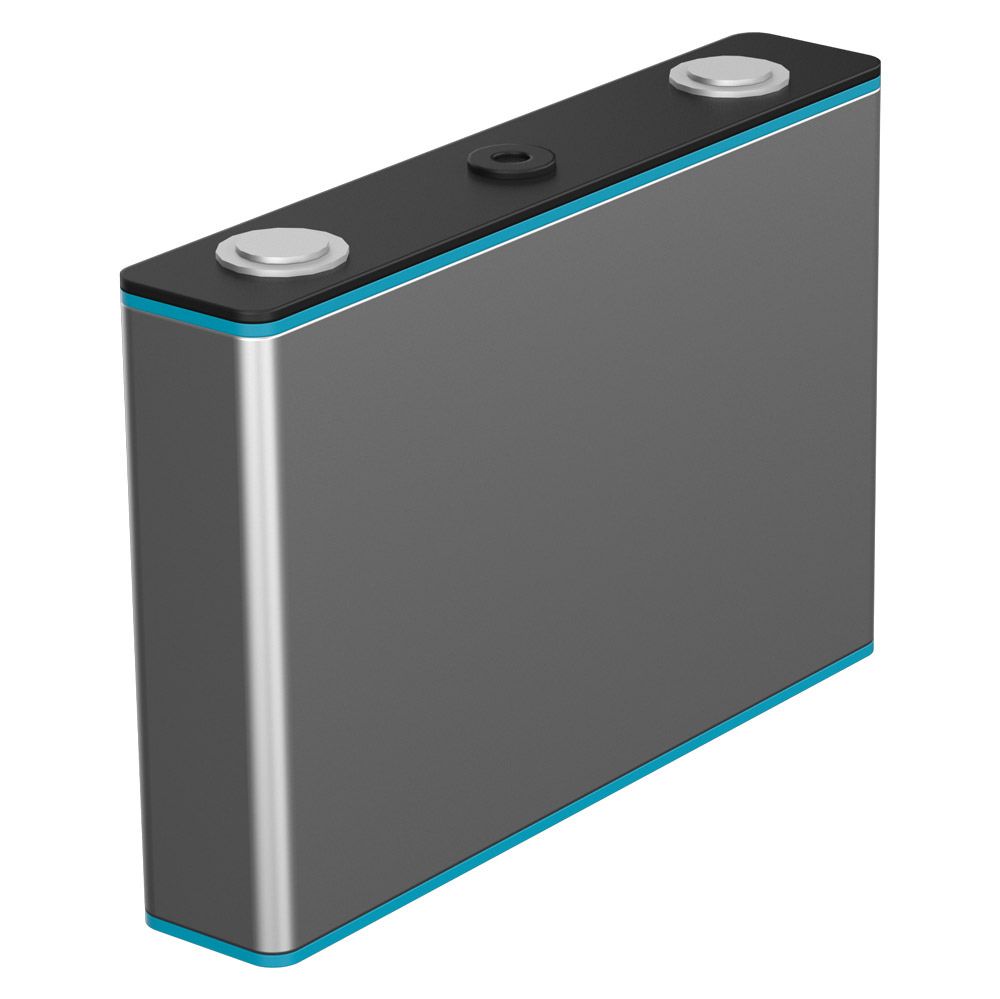

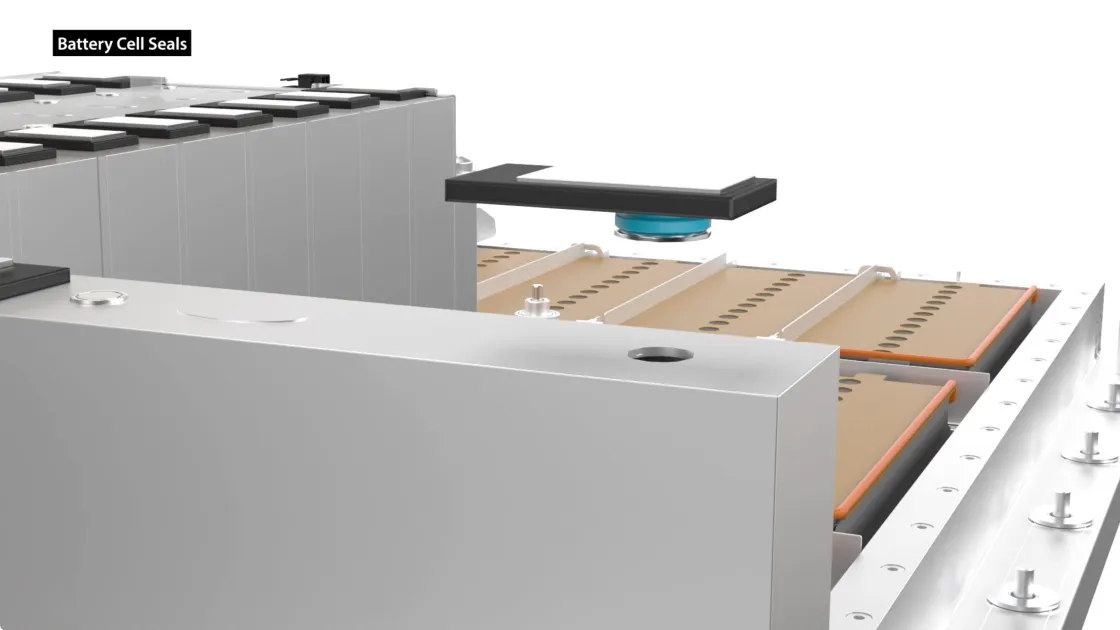

Battery Cell Seals

Datwyler is known as the watchmakers of the industry, since we can provide elastomer components for the most challenging applications while meeting the highest technical and safety standards. A century of experience in materials, design, and the processing of elastomer and multicomponent parts has placed us in the leading position of the marketplace.

Global Head of Engineering

Contact

For more information about Datwyler’s portfolio of

battery seals, their range of electrical, thermal, and

chemical properties, and how we can help improve

your battery safety and performance, please get in

touch.