Hydrogen production

Cutting-edge solutions

for green hydrogen production

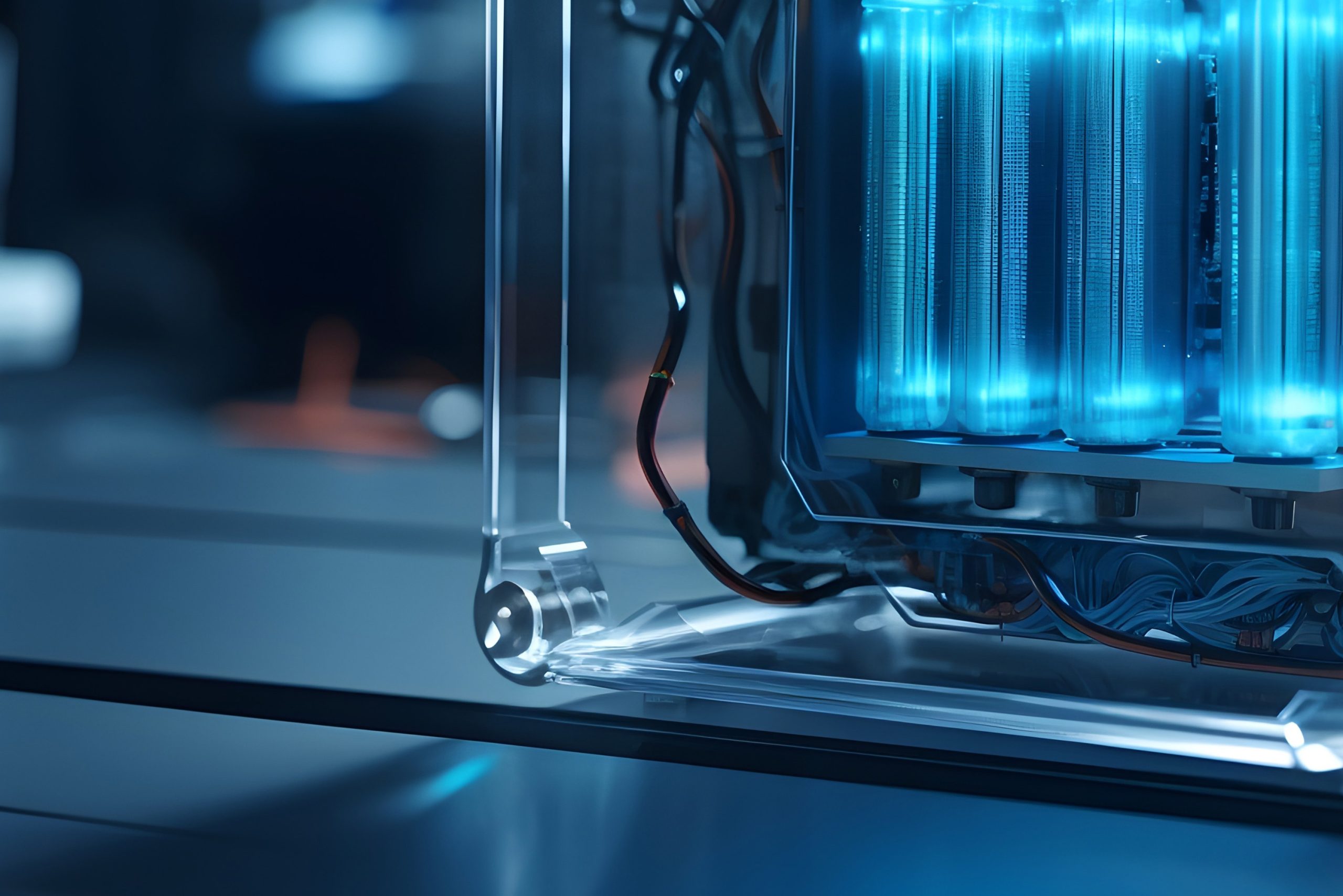

In order to produce hydrogen, electrolyzers apply an electrical current to water, causing it to separate into its basic elements, hydrogen and oxygen. This technology is fundamental in creating a sustainable source of hydrogen fuel, which is pivotal for clean energy initiatives and reducing reliance on fossil fuels.

Requirements

Our specialized sealing solutions, tailored to accommodate various electrolyzer technologies, are designed to meet the demanding requirements of your hydrogen production applications. With exceptional chemical resistance and a low hydrogen permeation rate, our elastomer components actively contribute to an efficient and reliable hydrogen production.

- Withstand pressures up to 50 bars

- Deal with temperatures 60-80°C (LT-PEM)

- High purity (cleanliness)

- Chemical resistance against hydrogen, oxygen, sulfuric acid and water

- Low hydrogen permeation rate

Product offering

Advanced seals for optimal electrolyzer performance

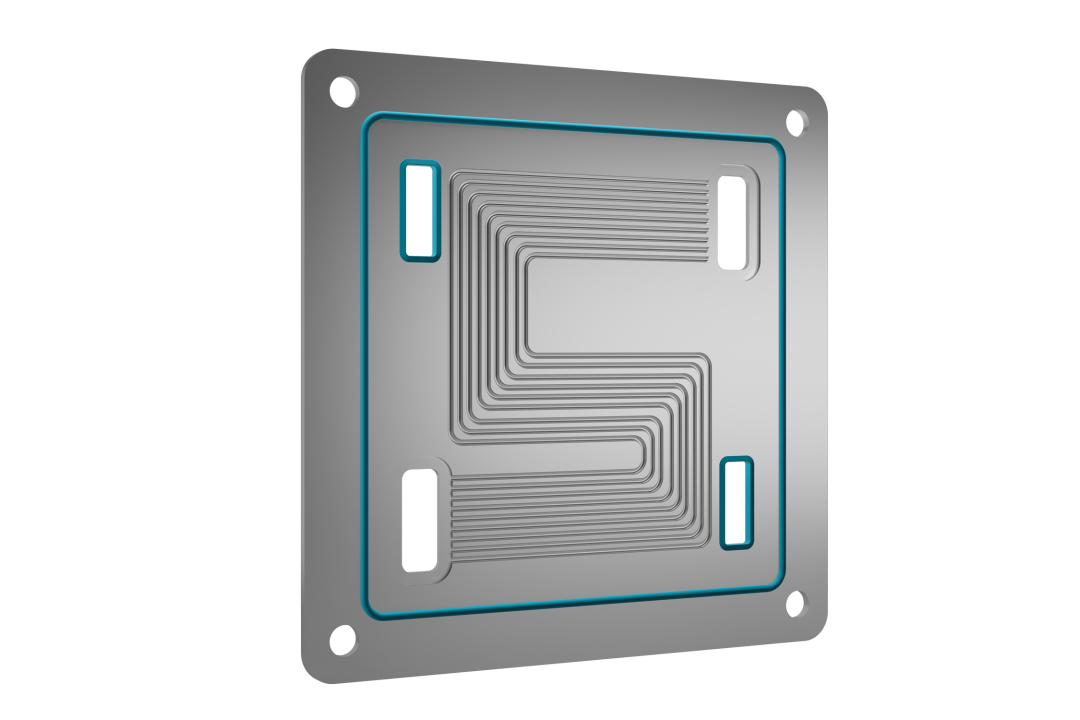

Achieve superior performance with custom designed seals for electrolyzer stacks and Balance of Plant (BoP), ensuring optimal efficiency and reliability.

-

Edge bonded gaskets

(elastomer to metal)

-

Overmolded seals

(elastomer to metal or composite plates)

-

O-rings

Recommended sealing material:

FKM

Electrolyzer plate with overmolded and edge-bonded seals

O-ring