Sealing the future of mobility

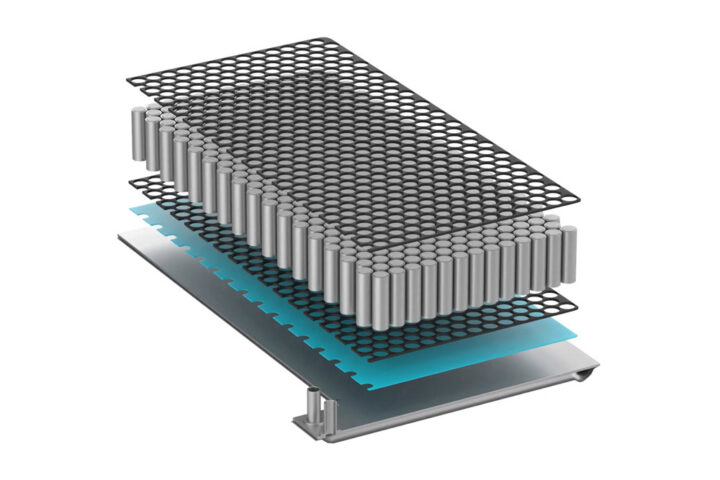

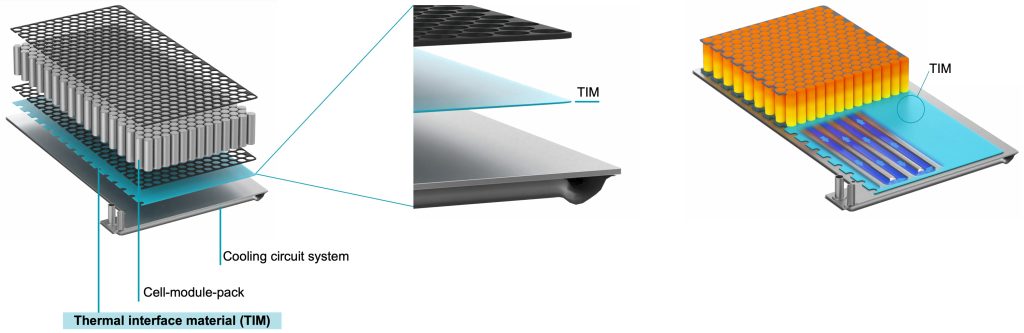

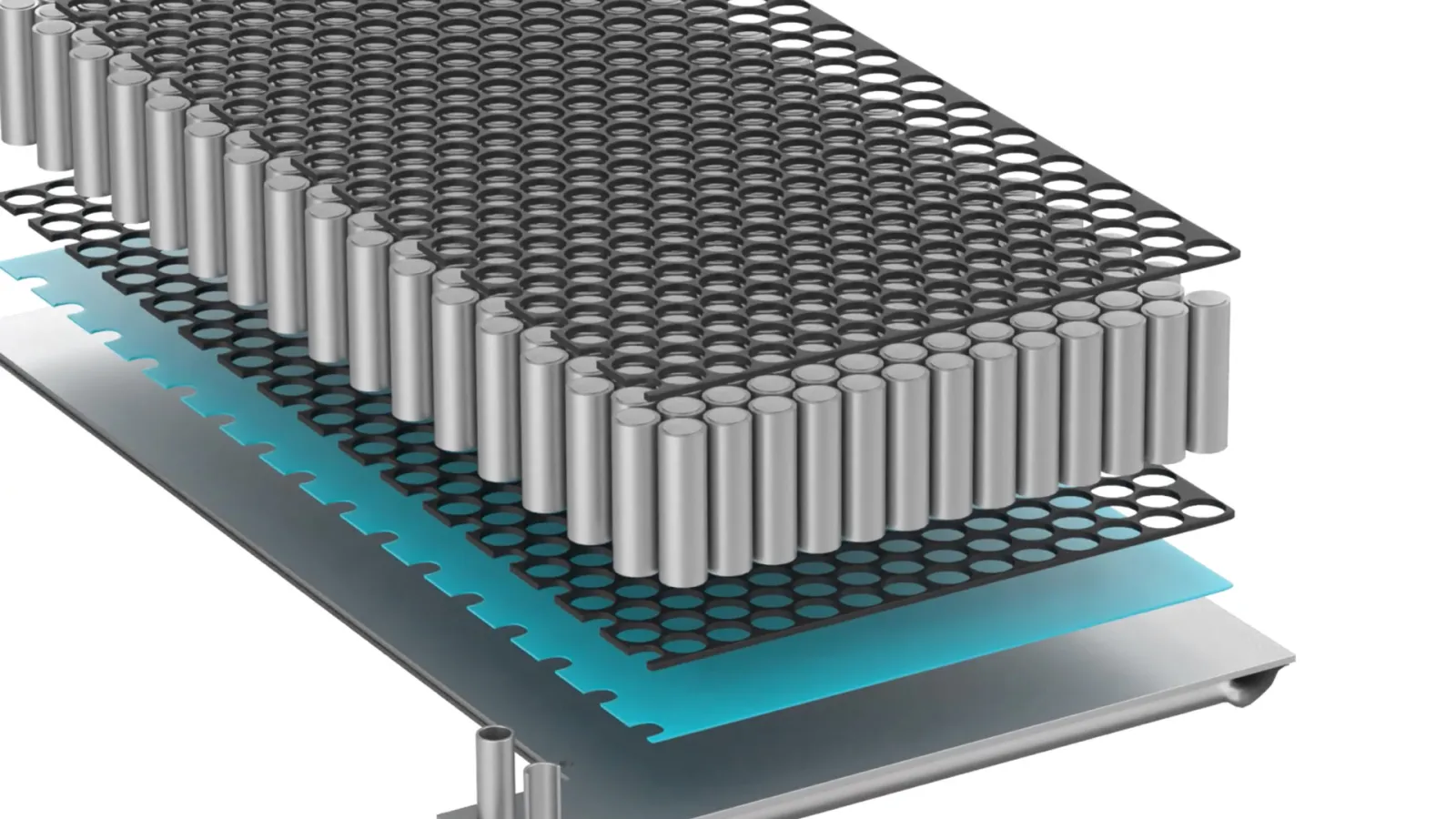

The electrification of vehicles has made everyone involved in the business of mobility completely reassess their product portfolios. Throughout this revolution, Datwyler has been one step ahead with its ETEMI™ project, developing a range of elastomer, LSR and thermoplastic materials able to conduct heat and electricity, and shield electromagnetic radiation, while retaining high levels of sealing performance. These exciting new materials are ideal for a range of applications, including sealing gaskets and thermal interface materials (TIMs) for battery packs, EMI shielding seals for sensors, and anti-static seals used to discharge vehicle components.

Properties

- Thin layer and low materials density supporting the lightweight aspect

- High thermal conductivity

- Electrical insulation

- Damping properties to absorb vibrations and protect the battery cell-module-pack

Function

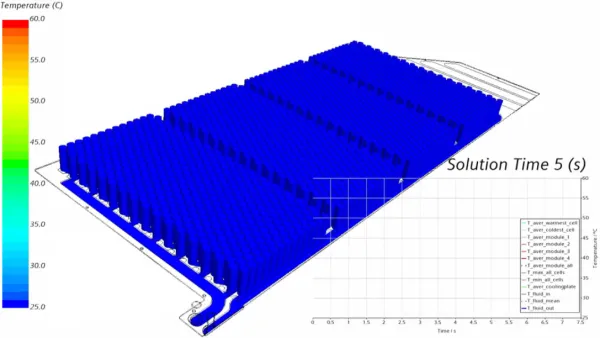

Supports the heat transfer from battery cells to the cooling systems to:

Keep the optimal operating temperature for long-lifetime of the battery

Prevent thermal runaway event

Thermal Interface Material (TIM) Technology for Battery Thermal Management

As the trend towards electrification continues, the ability to conduct electricity and heat, and shield components from electromagnetic signals, is increasingly important. Project ETEMI™ aims to create an entirely new category of materials designed to fulfil the highest requirements in sealing technology, delivering new capabilities in a safe and efficient manner.

Manager Material Development

Advantages

In-house expertise

The success of the ETEMI™ project comes from Datwyler’s deep knowledge of materials science and technology, combining specialist expertise and decades of experience in the mobility industry.

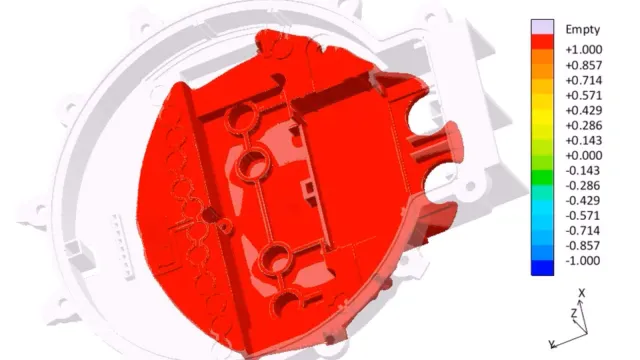

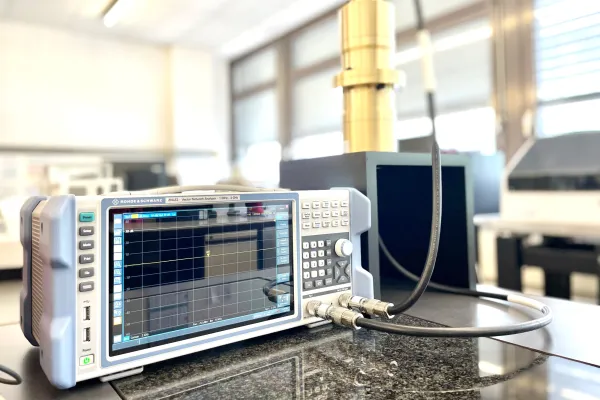

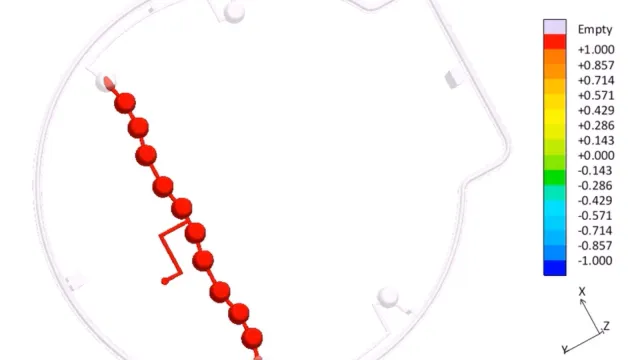

Advanced analysis and simulation

We understand that comprehensive analysis, simulation, and testing is key to the success of any new material, and our in-house analytical equipment and simulation technology offers exceptional accuracy for optimum performance.

Highest quality and testing standards

Datwyler’s strong portfolio of ETEMI™ materials conforms to all relevant quality and testing standards, including ISO 1853 and ASTM D911 for electrical conductivity, ASTM D4935-18 for EMI shielding, and DIN EN 993-15 for thermal conductivity.

Scale-up strength

Our global presence and collaborative attitude mean we can develop a wide range of new materials and take them from the laboratory to the production plant quickly and efficiently.

Contact

For more information about ETEMI and how these revolutionary materials can transform your mobility products, please get in touch with us.

Dr. Hediyeh Zahabi

Manager Material Development

Innovation & Design