Solution Design

Co-engineering Service

At Datwyler, our ideal customer project is one that’s built on collaboration. The

combination of ideas, inspiration, and knowledge from our experts and yours

provides a solution that fulfills all your requirements using the latest materials,

simulation technologies, and production processes. Our 360-degree support takes

you through all stages of development, from first designs to full-scale production

and beyond.

Applications

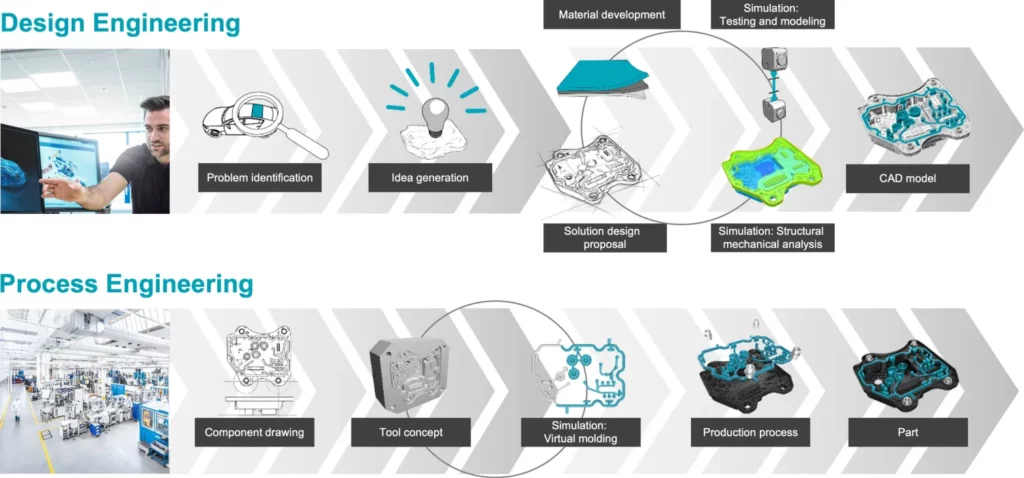

From initial assessment, idea generation, and early prototypes to simulation, testing, and molding, we offer the complete package of support for the most complex components, using our world-class state-of-the-art equipment and materials expertise to turn your designs into reality.

What differentiates Datwyler is the quality of our components and the way we can find solutions where others cannot. We align with our customers at every stage so that we can create a product that we are both happy with.

Product and Category Manager General Industries

Datwyler Advantages

Expertise and technology

Our co-engineering service gives you access to the latest simulation technology and the world’s leading experts in elastomer materials and multi-component parts for automotive systems in the mobility sector.

The highest standards

Whatever the project, we hold ourselves to the highest standards, from the quality of raw materials and knowledge of our experts, to the reliability of the final product and after-sales service.

Local-for-local solutions

Datwyler’s global network of facilities and experts ensures that you are never far away from one of our teams, ready and waiting to offer you their full support in product development.

End-to-end support

We have decades of experience in working with customers in automotive engineering projects, closely collaborating to take in all requirements and iterations to produce the ideal solution for optimum performance.

Contact

To find out more about our co-engineering service and how we can develop your ideal automotive solution, please get in touch with us.