One step ahead of an evolving industry

Brake Systems

Article | September 7, 2021

The way we control and stop a vehicle has been evolving for over two centuries, and as braking systems have gone from a simple wooden block and handle to the advanced systems in operation today, it was perhaps difficult to see how much further the innovation envelope could be pushed. That was, at least, until brake-by-wire technology emerged. The concept, which has already been proven to operate effectively in high performance applications such as Formula 1 vehicles, removes the physical connect between the brake pedal and the elements that apply the stopping force – replacing it with electrical signals transmitted ‘by-wire’.

The way we control and stop a vehicle has been evolving for over two centuries, and as braking systems have gone from a simple wooden block and handle to the advanced systems in operation today, it was perhaps difficult to see how much further the innovation envelope could be pushed. That was, at least, until brake-by-wire technology emerged. The concept, which has already been proven to operate effectively in high performance applications such as Formula 1 vehicles, removes the physical connect between the brake pedal and the elements that apply the stopping force – replacing it with electrical signals transmitted ‘by-wire’.

Firstly, the brake-by-wire system is designed to resemble, feel and operate exactly as a conventional vacuum booster or electrohydraulic system would to a driver today. The driver applies pressure to a brake pedal that is linked to a simulator, which in turn provides the feedback it would deliver in a standard system – i.e. the driver will feel that they have applied the brake through the pedal. As it is linked to a Human Machine Interface (HMI), it also has the ability to be designed, adapted and adjusted in many different ways, for example to suit a variety of driving styles, such as comfort, sport, or economy, depending on the customers’ unique specifications.

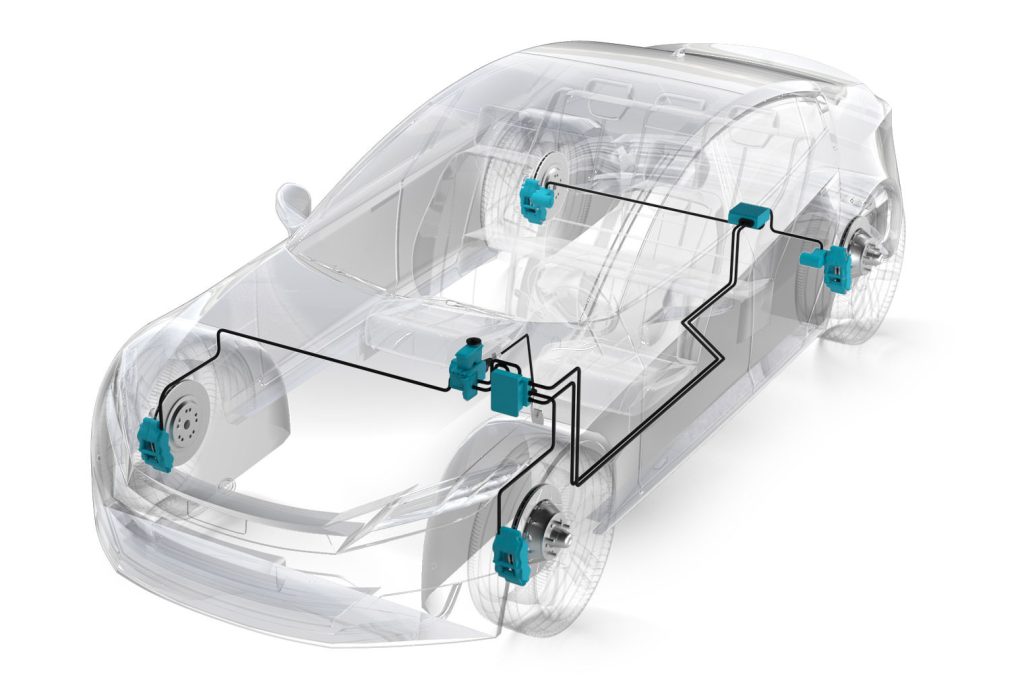

This pedal / simulator combination has a dedicated sensor that, once the pedal is depressed, is able to gauge the position of the pedal and then feed that information back to the vehicle’s brake control unit (BCU). Once received, the BCU then processes the information and determines the correct level of torque required by each braking corner, which in turn is relayed to dedicated electrohydraulic actuators.

Up to this stage, all systems on the market work the same. The ultimate goal for all is the real dry brake, where no hydraulic fluid is necessary. This means that all four calipers are electrically controlled and actuated by electric actuators. Since the market, the OEM and particularly the end customer still lack confidence in such a completely decoupled system, “hybrid systems” are being promoted in parallel today, where a certain intervention or redundancy is still provided by a partial hydraulic circuit, for example on the front axle, in the event of failure of an electric module. The actuation in such “dry-wet” systems is identical. However, here the electronic signal is passed on to the electrohydraulic actuators and thus the brake calipers are operated hydraulically. These actuators then convert electrical energy sourced from the vehicle’s battery to hydraulic pressure, which is then applied at the determined level. In general, all variants of brake-by-wire enable far more efficient braking and shorten both the system’s reaction time and the braking distance.

All four brake discs are standard components, as are the front calipers, however the rear calipers are pure electrical and are therefore controlled by the BCU. Again, the electrical energy from the battery is converted into what is known as clamping force, which is applied in relation to the force target identified by the BCU. This pure electric caliper can also be used where an electronic parking brake function is required, adding additional functionality.

Sustainability through weight reduction

Sustainability through simplified design

Sustainability through recuperation of energy

Reduction of noise and vibration

Enhanced safety through faster response times, reducing stopping distances

Enhanced safety through space saved, increasing crumple zone areas

Increased range

Ability to collect data and to apply it in real time to improve driver experience

Of course, brake-by-wire technology will take time to become a mainstream element within the mobility sector, but manufacturers and suppliers of components are working in partnership to ensure the benefits of this revolutionary technology can be brought to the driving public as soon as is possible.

Datwyler is the market leader for system-critical engineered elastomer solutions in brakes applications and is already involved in numerous new generation brake projects such as brake-by-wire and electric parking brake technology. Thanks to close and trustful engineering relationships with market leaders over decades and a strong expertise in Materials Development and Design-to-specification, along with Industrialization Power and Operational Excellence, Datwyler is the right partner for future-oriented brake and new mobility projects.