The power of innovation for battery systems

Article | June 12, 2023

Discover how Datwyler’s materials and components are transforming the performance of batteries to make electric vehicles fit for the future.

Every area of the automotive sector, from small vehicles to large trucks, is undergoing a fundamental transition, with every part of the power system being redesigned and redeveloped to make the important shift from fossil fuel to electric.

Of course, for this transition to be successful, the main focus of development has to be the battery. Its power, capacity, charging rate, size, weight, and safety are all vital factors in the overall performance of the vehicle, so companies are placing a huge amount of focus on this part of the vehicle.

As one of the world’s leading manufacturers of elastomer seals, Datwyler understands the key role these components have in battery systems, and how they make a significant difference to the performance, longevity, and safety of the battery. Our global team of experts are constantly developing new solutions to the challenges of the new generation of lithium-ion (Li-ion) batteries – here are just a few of those solutions.

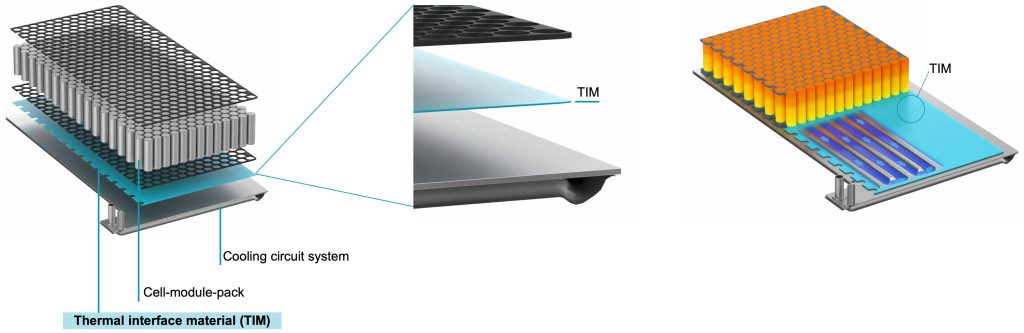

Thermal interface materials (TIM)

One of the main challenges of Li-ion batteries for vehicles is thermal management. Used in electric vehicles for their relatively higher power and energy density, Li-ion batteries are highly attractive to manufacturers. However, there are certain drawbacks to these batteries, such as the risk of thermal runaway, as well as the challenge of the degradation of components such as electrolytes at higher temperatures. For safety and long-term performance, it is crucial that these batteries remain within a certain temperature range, something that thermal interface materials can help with.

Made of an elastomeric material with high heat conductivity, thermal interface materials are designed to evacuate heat efficiently from Li-ion batteries by reducing the contact thermal resistance. These unique materials are placed between battery cells and the cooling system in the form of conventional rubber pads, and can influence almost every aspect of a battery’s performance, from charging and discharging at high C-rates to controlling the temperature of batteries and preventing thermal runaway.

Right now, there is considerable interest in thermal interface materials, with battery and vehicle manufacturers keen to use the latest technologies to improve the performance and safety of battery systems. The ability of thermal interface materials to offer effective thermal management for batteries in a range of sizes and thicknesses – as well as low weight – is a compelling development, and samples are currently in production.

Properties

Thin layer and low materials density supporting the lightweight aspect

High thermal conductivity

Electrical insulation

Damping properties to absorb vibrations and protect the battery cell-module-pack

Function

Supports the heat transfer from battery cells to the cooling systems to:

Electromagnetic Interference (EMI) shielding

Another challenge for battery electric vehicles is electromagnetic interference. The battery system, electric motor, and charging system in electric vehicles can produce strong electromagnetic interference that impacts vehicle electronic components. With increasing amounts of electronics and sensors being used in vehicles, particularly with the development of Advanced Driver Assistance Systems (ADAS), it is vital that these electromagnetic waves are suppressed, and one solution is the use of ETEMI, electrically conductive or electromagnetic interference (EMI) shielding materials.

Currently in development at Datwyler, these unique materials are supposed to provide effective EMI shielding, blocking electromagnetic waves to protect the sensitive electronic systems of electric vehicles.

Answering the challenges of the future

Thermal management and EMI shielding are just two of the challenges involved in developing elastomer materials and solutions for the next generation of batteries. The constantly changing chemistry of the battery system needs a corresponding change in the elastomer’s chemical resistance, so materials are being adapted all the time. Given the enormous importance of battery systems, Datwyler is working on the development of new materials and components with highest priority and hand in hand with market requirements.

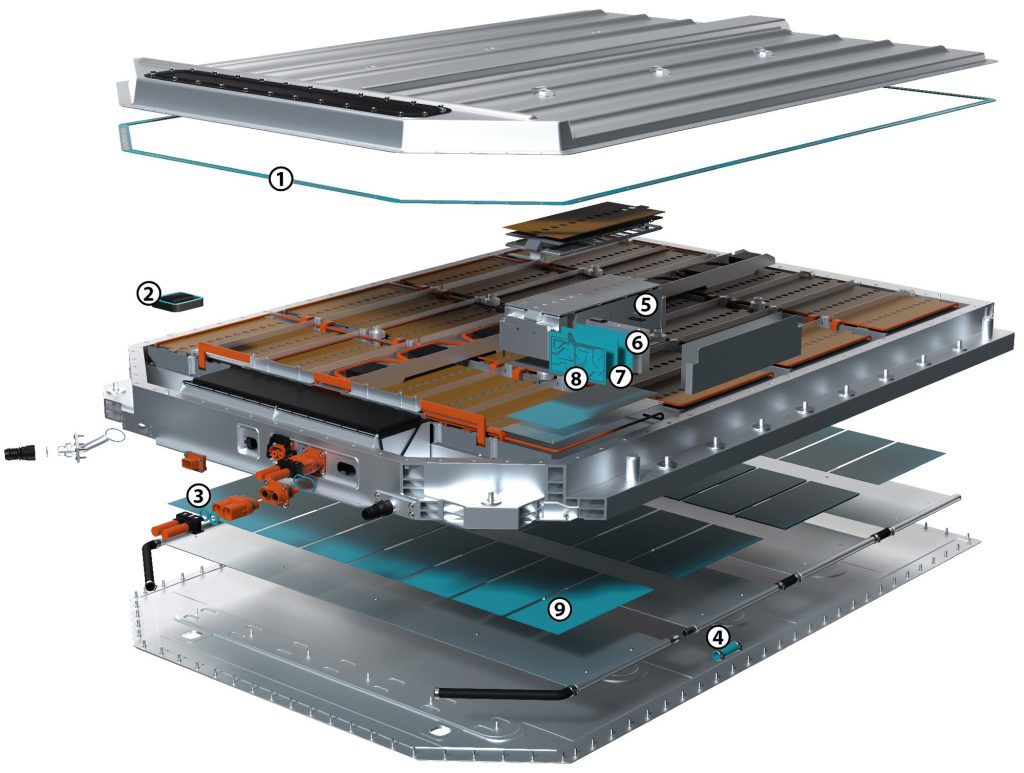

One essential development is the battery pack gasket, which uses an advanced elastomer with or without thin metal plates to offer a highly reliable sealing solution that provides accurate dimensions for precise and rapid mounting. This gasket also enables easy opening of the battery pack, delivering in-built sustainability plus easy transportation.

Looking further into the future, we are working on a number of solutions at different levels of the battery system. One trend at the moment is the use of immersion cooling to bring down the temperature of increasingly powerful battery systems. Datwyler is in the process of developing materials and seals that are optimized for the new coolant chemistries.

Another interesting area is the development of battery monitoring solutions. With the many changes in battery systems, safety regulations are becoming more stringent, which requires a number of new monitoring challenges. We are investigating the potential of components and materials in answering these challenges.

Battery pack seal (foldable and full elastomer gasket)

Safety valve seal

Electrical connector seals

Cooling plate connector seals

Battery cell electrode seal

Compression pad

Thermal propagation protection sheets

Cell monitoring sensor

Thermal interface material

The key to Datwyler’s strength in developing new solutions lies in the combination of in-depth expertise, materials knowledge, and an ability to work closely with our customers for co-engineering projects.

By understanding your challenges and applications, we push ourselves towards the ideal solution, bringing us closer to a mobility sector reliant on sustainable energy.

Author

Andreas Proksch

Application Engineer Europe & Americas

Dr. Amir Yazdani

Advanced Technology Development Manager

Datwyler Business Unit