Hydrogen end-use

Advanced seals for optimal performance of your hydrogen systems

In the world of green hydrogen, the integrity and safety of hydrogen systems depend on advanced sealing technologies. Whether it’s fuel cells, internal combustion engine, domestic heating systems, reliable seals play a vital role in preventing leaks and ensuring optimal performance of your systems.

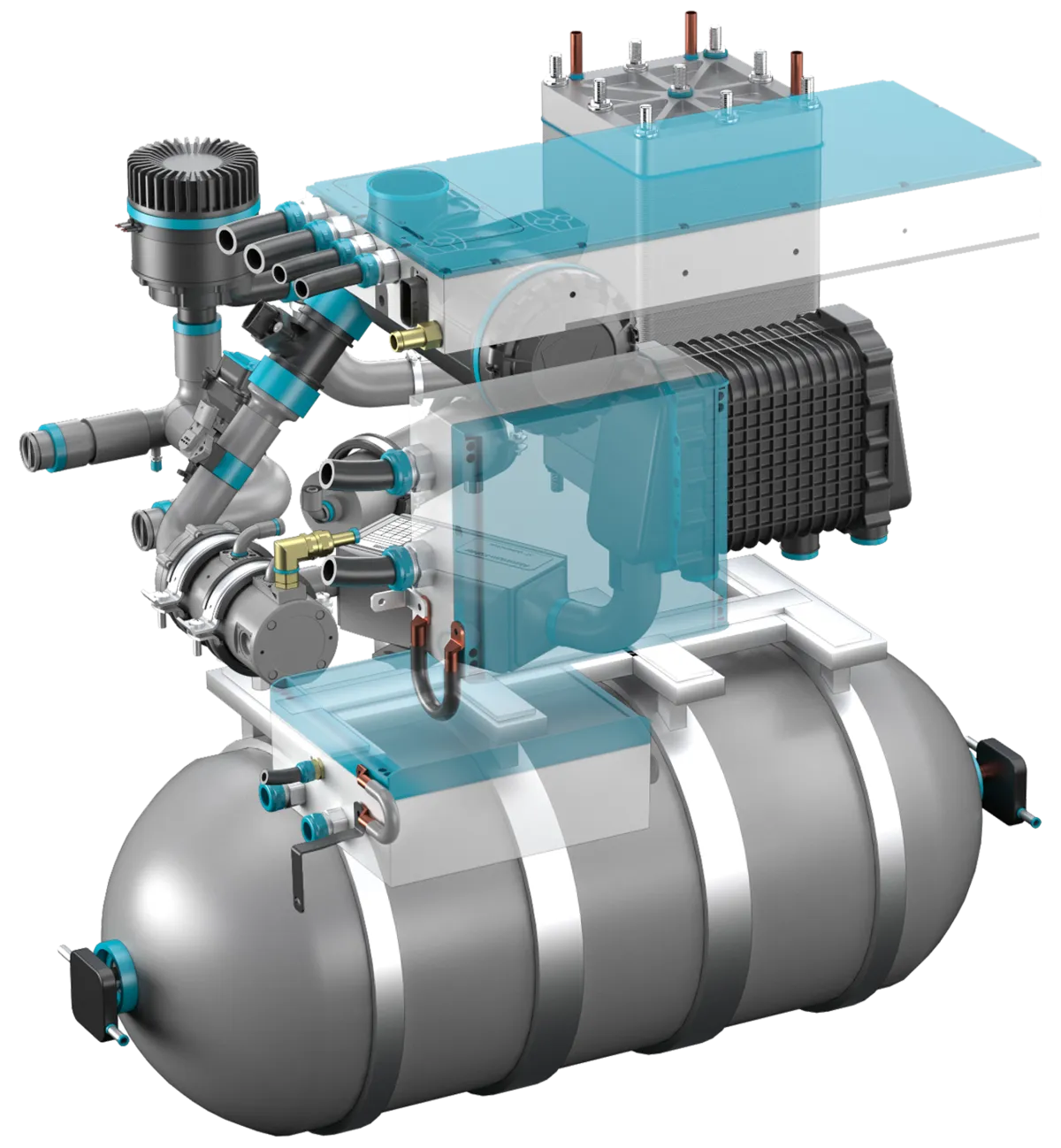

Fuel cell

A fuel cell is a system that converts chemical energy into electricity through a chemical reaction between a fuel (often hydrogen) and an oxidizing agent (often oxygen). Fuel cells offer a sustainable energy solution with the potential to power everything from vehicles to entire energy grids with minimal environmental impact.

Requirements

- Withstand pressures from 1 to 4 bars

- Deal with temperatures 20°C to 100°C (LT-PEM) and up to 220°C (HT-PEM)

- High purity and cleanliness (no leachable and extractables that would poison the catalyst)

- Chemical resistance against hydrogen, sulfuric acid (LT-PEM), phosphoric acid (HT-PEM), hot air and water

- Low hydrogen permeation rate

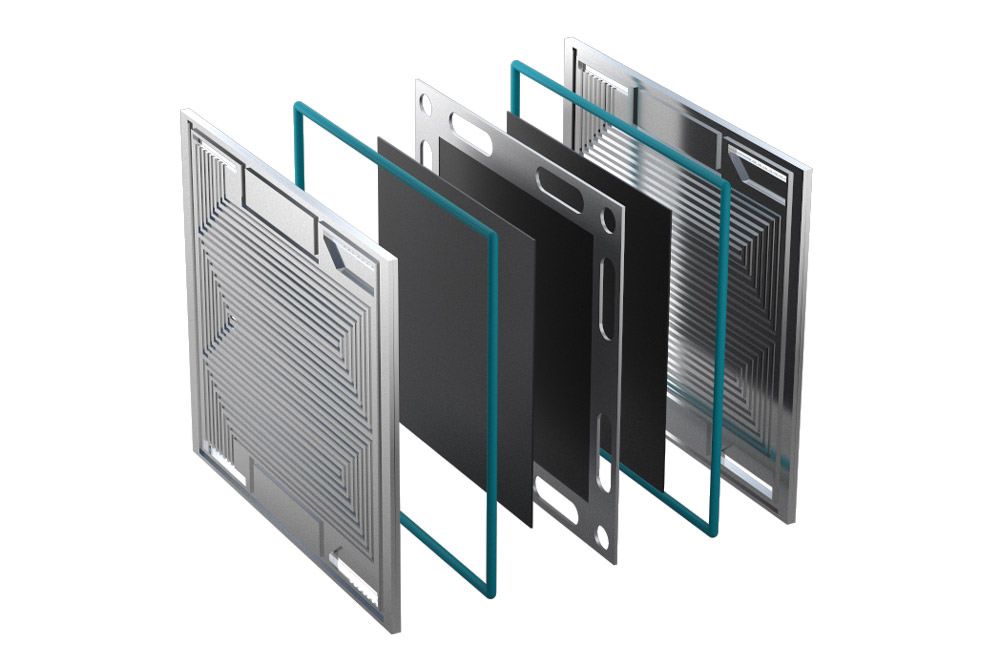

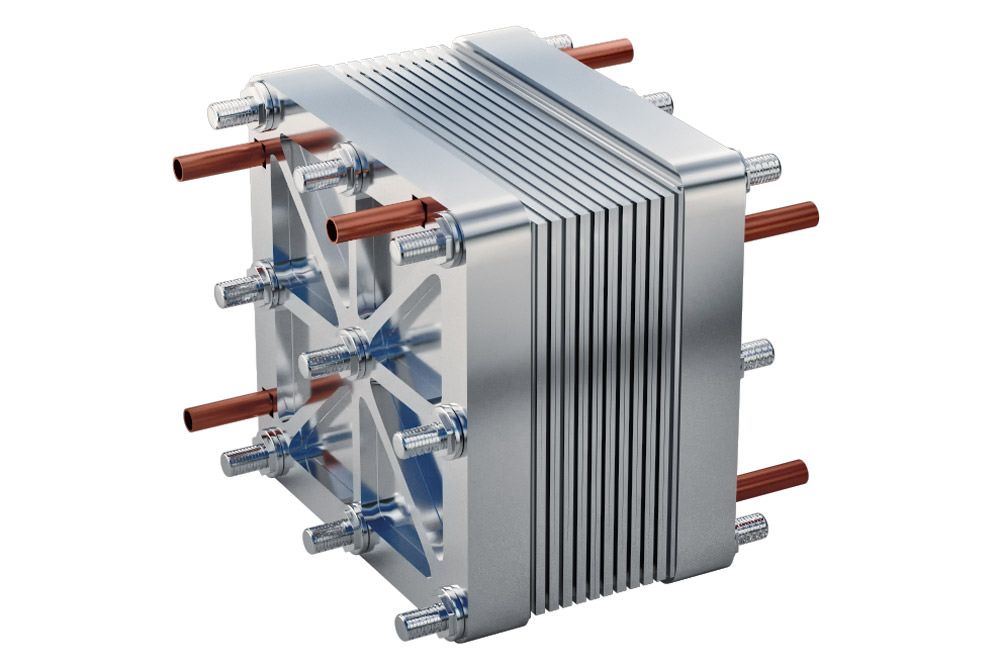

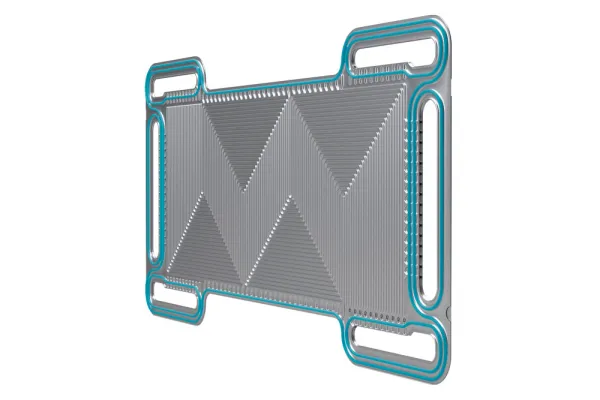

Fuel cell stack

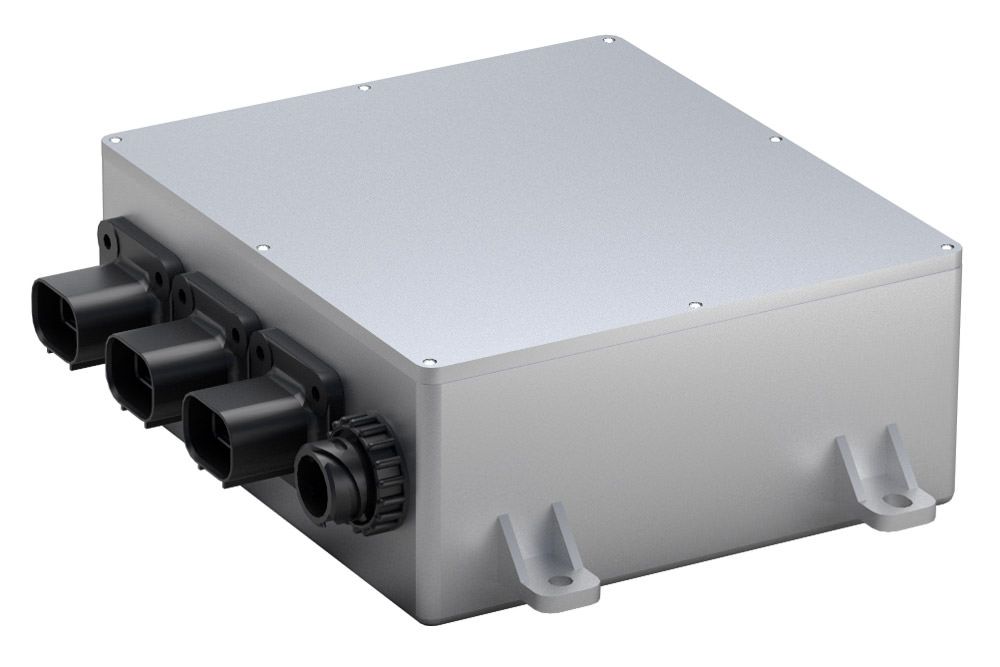

Fuel cell auxiliary systems

Product offering

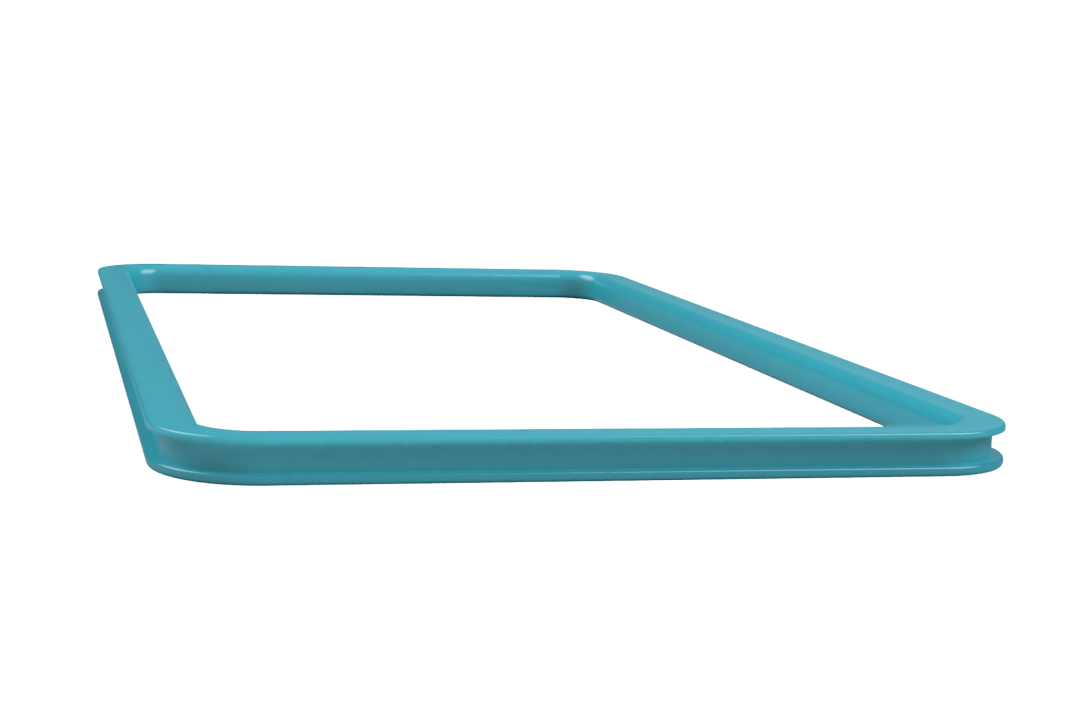

Plate seals for fuel cell stacks

-

Overmolded seals

(elastomer to metal or composite plates)

-

Composite bipolar plates with sealing

(thermoformed, overmolded, screen-printed, or dispensed)

Recommended sealing material: FKM, EPDM, LSR

Bipolar plate with overmolded seals

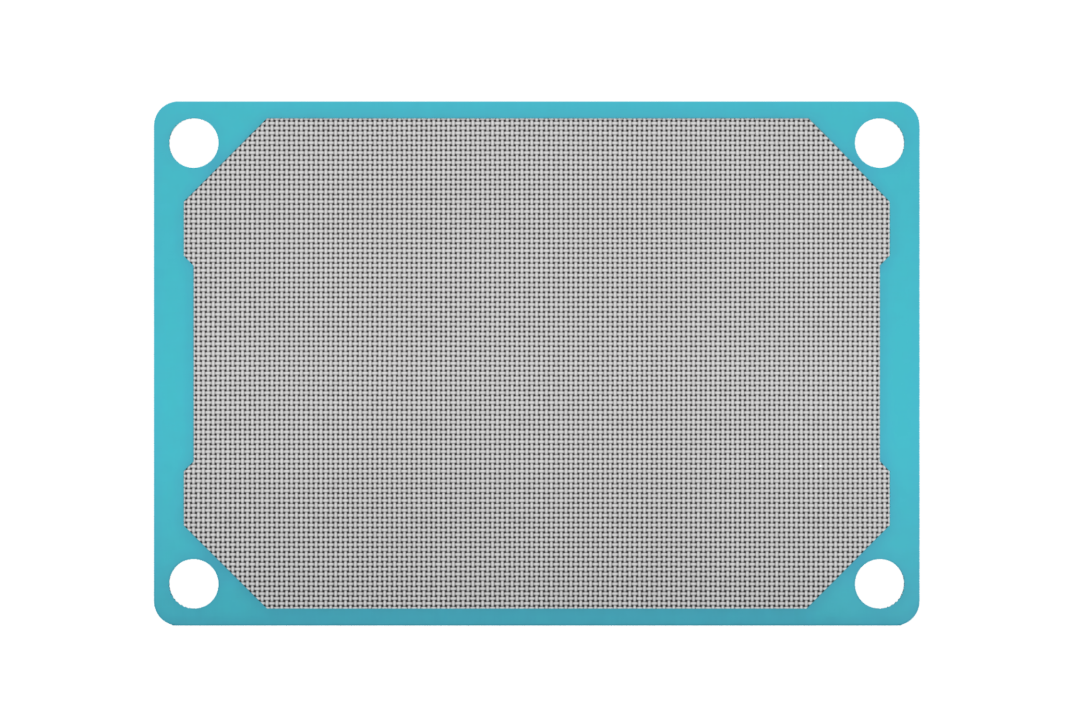

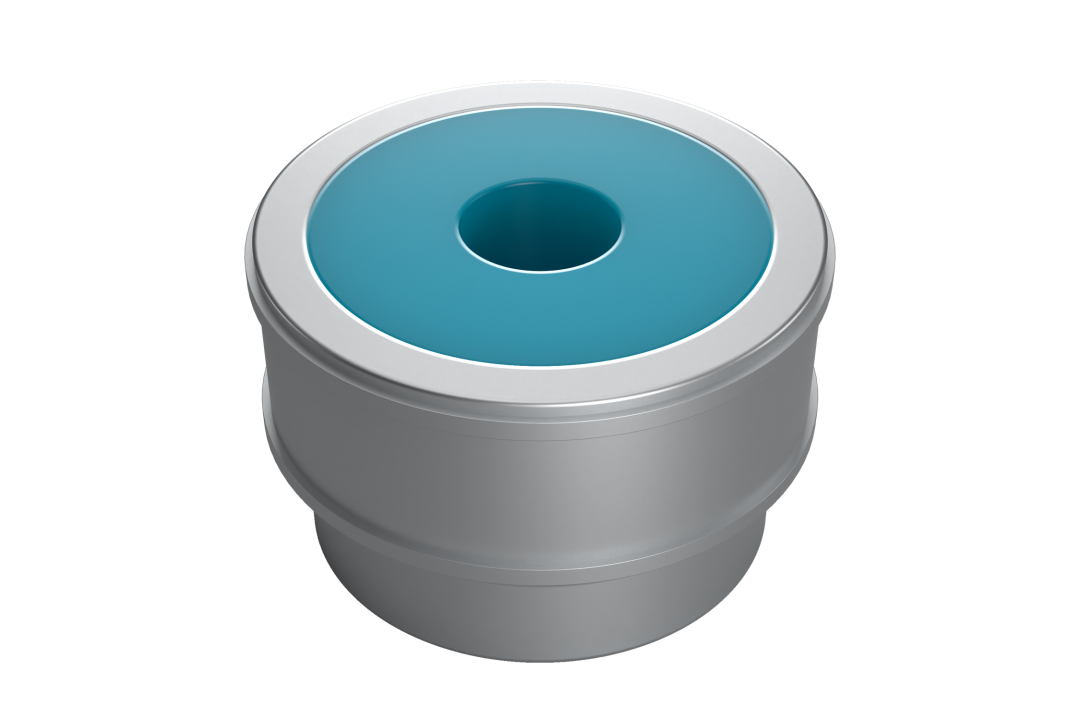

Seals for auxiliary systems

We provide highly durable elastomer sealing solutions for fuel cell auxiliary systems such as O-rings, static seals, overmolded seals.

Filter membrane sealing

O-ring

Static seals in various shapes

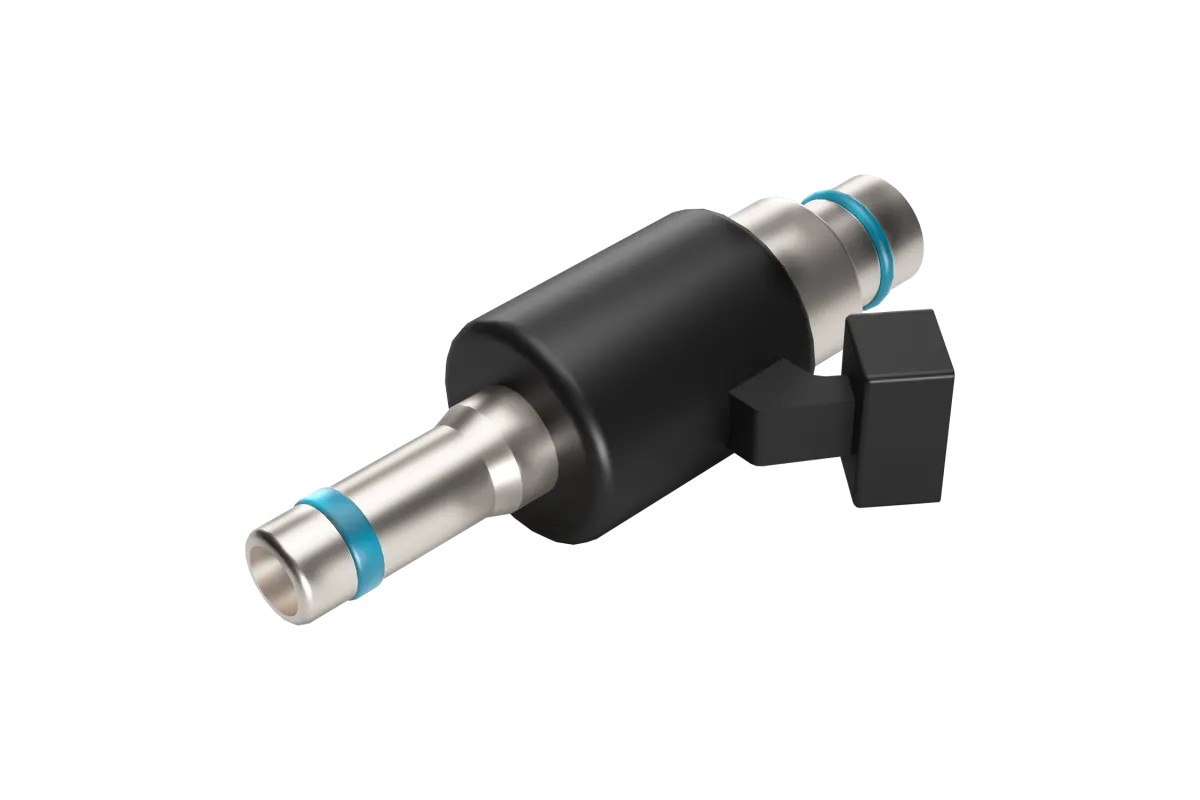

Hydrogen injector

The need for highly reliable components in hydrogen fuel systems becomes increasingly critical. While hydrogen injectors play a vital role in fuel delivery, their performance heavily relies on the quality of sealing solutions they are paired with.

Hydrogen injector

Requirements

Our seals are engineered to withstand the unique challenges posed by hydrogen’s small molecular size and high-pressure requirements, preventing leaks and maintaining system integrity.

(Port fuel injectors)

- Withstand pressure up to 15 bar

- Deal with temperature from –40°C to 125°C

- Hydrogen compatibility

Product offering

Seals for H2 injectors

-

Tip seals, lower and upper O-rings

-

Elastomer to metal bonded seals

-

Sealing disc for hydrogen injection port

Recommended sealing material: FKM

Elastomer to metal bonded seal

Sealing disc

O-ring

Fueling and refueling

Hydrogen fueling and refueling stations are crucial for the wide adoption of green hydrogen as a clean energy source.

Fueling nozzle

Durable elastomer components for hydrogen stations

- Elastomer-metal bonded seals

- O-rings