Simulation

Optimizing products and

production processes

In the development of all new elastomer materials and components, effective

simulation and testing are vital for the long-term performance of the final product.

Whether it’s structural mechanical analysis or virtual molding, Datwyler combines

the latest software with over one hundred years of experience in material

development to optimize its products and production processes, working with you

to deliver ideal long-term solutions.

The virtual

solution to a

physical challenge

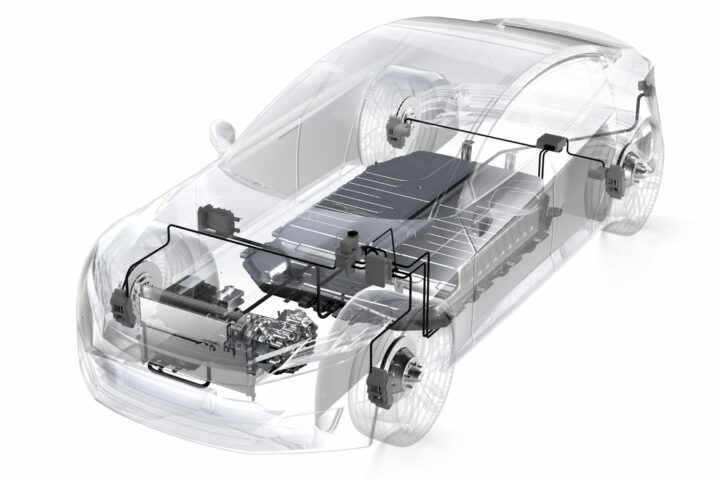

The dynamically evolving mobility sector has brought about a demand for components and materials that offer reliable performance across a broad range of applications. The need for multi-functional components with specific physical and mechanical properties requires increasingly complex simulation techniques to account for structural, thermal, and electrical nonlinearities, as well as the interdependencies between different physics to develop virtual models that are as close as possible to reality.

Already a global leader in elastomer component simulation, Datwyler is developing its expertise in new areas such as multi-physics simulations and the virtual validation of entire assemblies, offering customers the digital technology and deep knowledge required to drive the mobility industry forward.

We begin building simulation models as early as possible, sometimes even before the first customer meeting. This helps us visualize ideas, designs, and product functionality very early in the project and creates a close relationship with the customer right from the start.

Head of Engineering

More about

Datwyler Advantages

Latest simulation technology

Datwyler uses the latest simulation software to develop virtual products and production processes, including Ansys® for structural mechanical analysis, SIGMASOFT® for virtual molding, and MATLAB® for testing and modeling. Our comprehensive expertise in all simulation platforms results in highly sophisticated models that accurately translate to physical products.

Deep material knowledge

Since we already develop and manufacture the majority of rubber materials for our components, we have characterized a broad range of compounds and elastomers by their physical properties and mathematical material models, saving you time and costs.

Joined-up thinking

At Datwyler, the development of a new component or material involves teams from different areas, all experts in their fields working together to engineer the optimum solution to your challenge. Having a global network of in-house expertise makes the entire simulation phase a smooth, efficient, and rewarding experience.

Close customer relationships

Whether you require our complete simulation service or just need support in certain areas, our team of experts and the latest technology will help you to realize your product’s full potential.

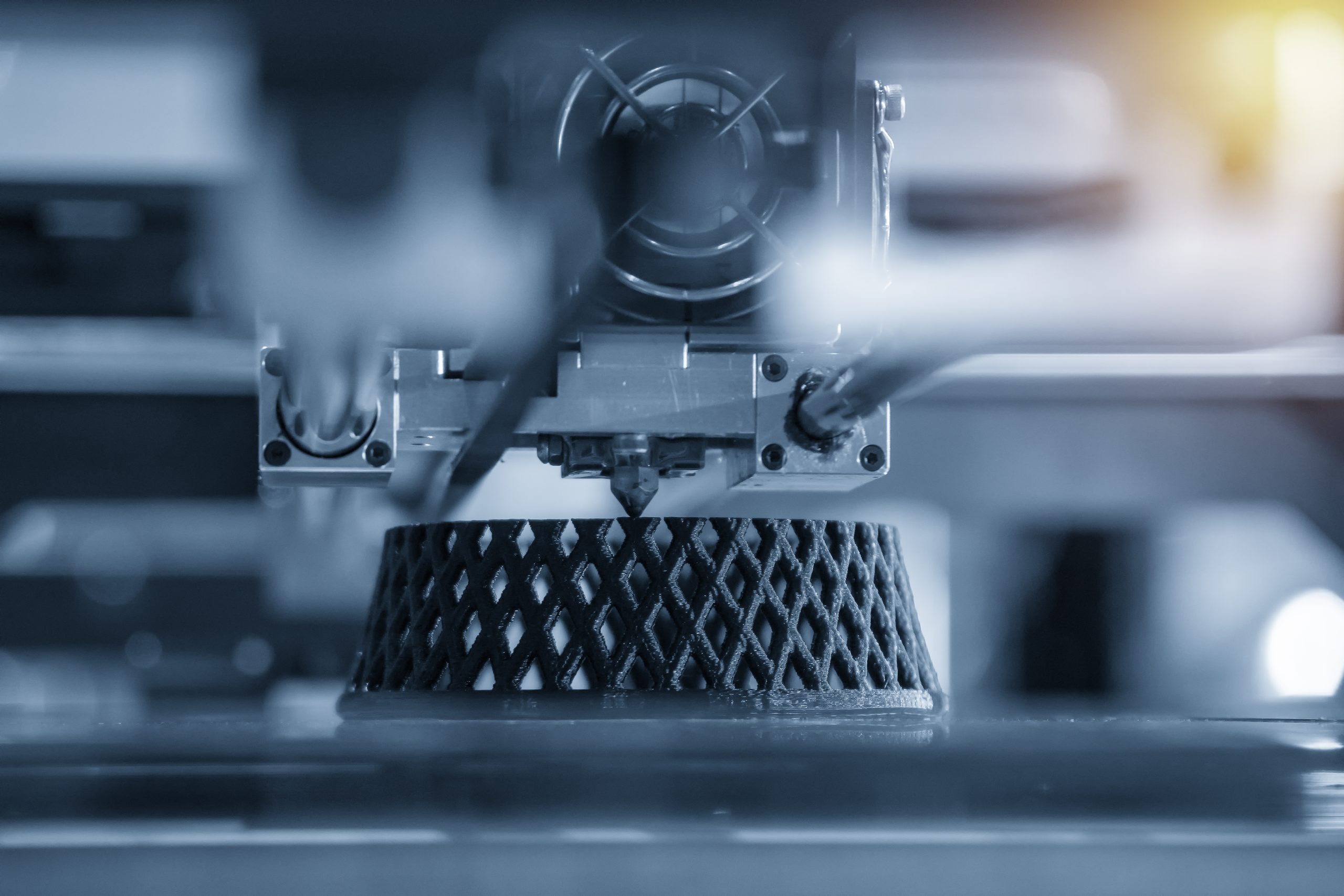

Sustainability through simulation

By optimizing production processes before the existence of trial tools, virtual molding significantly speeds up tool and process development while helping to reduce the amount of waste. Virtual molding also systematically examines the impact of various process parameters to identify the most energy- and cost-efficient process conditions.

datwyler in the media

Contact

Find out more

For more information about Datwyler’s simulation services and how we can enhance your existing simulation and testing capabilities, please get in touch with us.

Dr. Rudolf Randler

Head of Engineering

Innovation & Design