Materials and compliance

Rubber compound

SoftPulse™ electrodes consist of electrically conductive clean elastomer. Hardness of the material is 83 +- 5 Shore A.

Coating

The skin-facing areas are coated with silver/silver chloride. Standard color is grey, black coating is also available.

Biocompatibility

Thanks to a careful selection of ingredients for the rubber compound and an optimized processing, SoftPulse™ electrodes fulfill all the requirements for skin contact according to ISO 10993-5 (cytotoxicity) and ISO 10993-10 (skin irritation & skin sensitization)

Manufacturing standards:

- ISO 9001

- ISO 14001

- ISO 45001

Performances

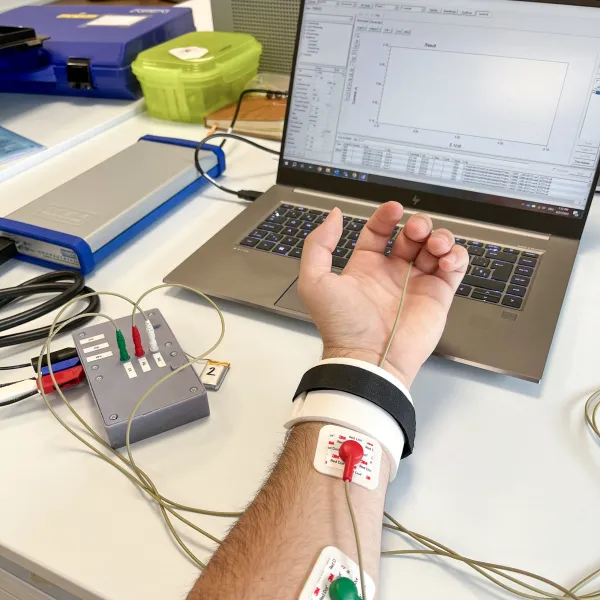

Electrode Tissue Impedance (ETI)

SoftPulse™ electrodes offer an average ETI of 25-200 kOhm at 10 Hz which allows superior signal quality and reduced noise. The unmatched accuracy and ease of use make SoftPulse™ the best in class solution for your dry bio-signal acquisition needs.

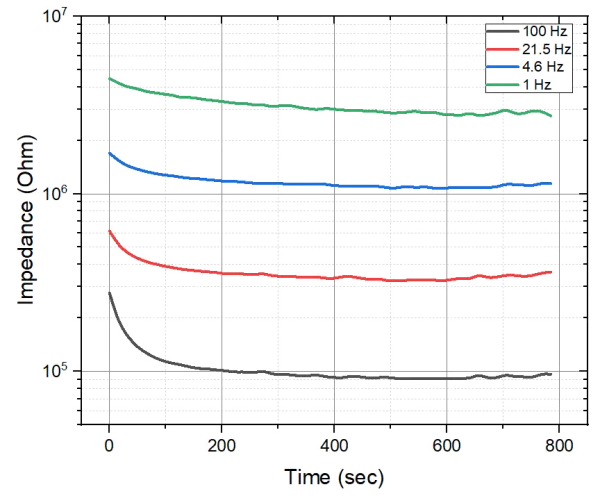

Equilibration Time

Short equilibration time ensures quick and accurate bio-signal acquisition, resulting in reduced setup time, improved patient experience and increased efficiency in clinical and at home settings.

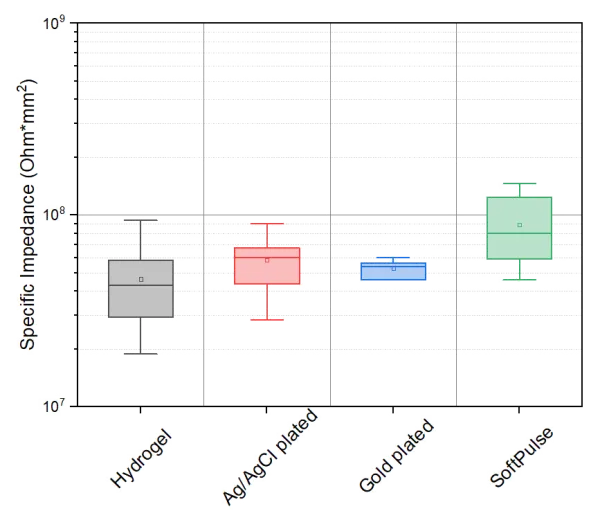

Benchmarking

In a comparison with alternative electrode technologies (hydrogel-based single use electrodes, Gold plated metal and Ag/AgCl plated metal), SoftPulse™ electrodes show similar specific impedance. At the same time, SoftPulse™ electrodes offer the benefits of re-usage of the electrode, dry application, comfortable feel, customization possibilities and easy integration in any kind of wearable.

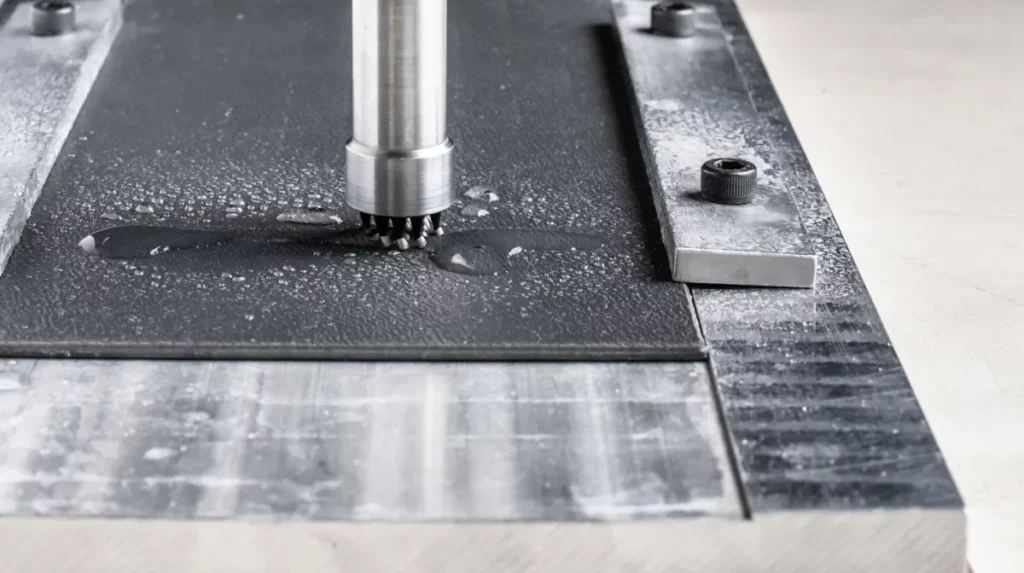

Abrasion stability

SoftPulse™ electrodes allow repeated use in harsh and abrasive environments. SoftPulse™ electrodes retain their properties even after hundreds of applications in dry and wet conditions.

Environmental stability

SoftPulse™ electrodes are stable to ageing process and environmental conditions. Performances are retained upon direct sun exposure or prolonged exposure to sweat. No influence has been observed by storing the electrodes at extreme temperatures between -25°C and +150°C.

Production

technology

Molding

SoftPulse™ electrodes are produced with state of the art rubber molding processes. Thanks to Datwyler’s core competencies, all production steps are performed in-house and can be tuned according to customer and product needs. SoftPulse™ production takes place within a clean and controlled production environment.

Coating

Various coating processes have been developed to allow coating of different surface morphologies as well as electrode designs.

Customization

SoftPulse™ electrodes can be tailored to meet specific customer needs. Production tools are produced in-house according to the most stringent industrial standards. We offer our customers engineering support from an idea till serial production. Overmoulding of SoftPulse™ with metal, plastic or other materials can be offered to reach better performances and easier integration of the electrode in the final product.

Contact

To find out more about our SoftPulse™, our services, and how we can help you, please get in touch with us.