Downloads

Media library

We provide all interested parties with various kind of media of the Datwyler Group from our extensive media library, free of charge.

Datwyler Group

High-tech company

Datwyler already obtains 36.6% of its electricity needs worldwide from renewable sources.

jpg,

1.14 MB

The Swiss plant in Schattdorf is one of six Datwyler sites with its own photovoltaic system.

jpg,

838.67 KB

The Technology and Innovation Labs accelerate the development process and enhance speed-to-market for customers.

jpg,

262.44 KB

The state-of-the-art equipment promotes the development of future-oriented surface technologies and material solutions.

jpg,

4.31 MB

Division

Healthcare

Datwyler offers best-in-class vial packaging solutions for the pharmaceutical and biotech markets. Datwyler’s vial solutions are available in a range of sizes, a variety of elastomer compounds, with optional coating technology, packaged ready-for-sterilization, ready-to-use, or in Rapid Port Transfer bags, and can be either gamma or steam sterilized.

jpg,

156.02 KB

With (smartlink: ultrashield), Datwyler is the only supplier capable of offering both film and spray coating technologies for elastomeric closures for injectable drugs.

jpg,

675.31 KB

Datwyler’s (smartlink: starterpack) is the ideal offering to tackle small quantity component needs. Specially designed to provide its customers with sealing solutions for every stage of drug development, Datwyler offers a single source solution to take the drug from discovery through delivery.

pdf,

2.43 MB

tif,

2.39 MB

Datwyler’s team of experts is constantly searching for innovative solutions in the parenteral packaging industry. Our research and development capabilities and expertise continuously provide new and improved packaging solutions that are ideal for each customers’ drug product.

pdf,

2.43 MB

tif,

11.17 MB

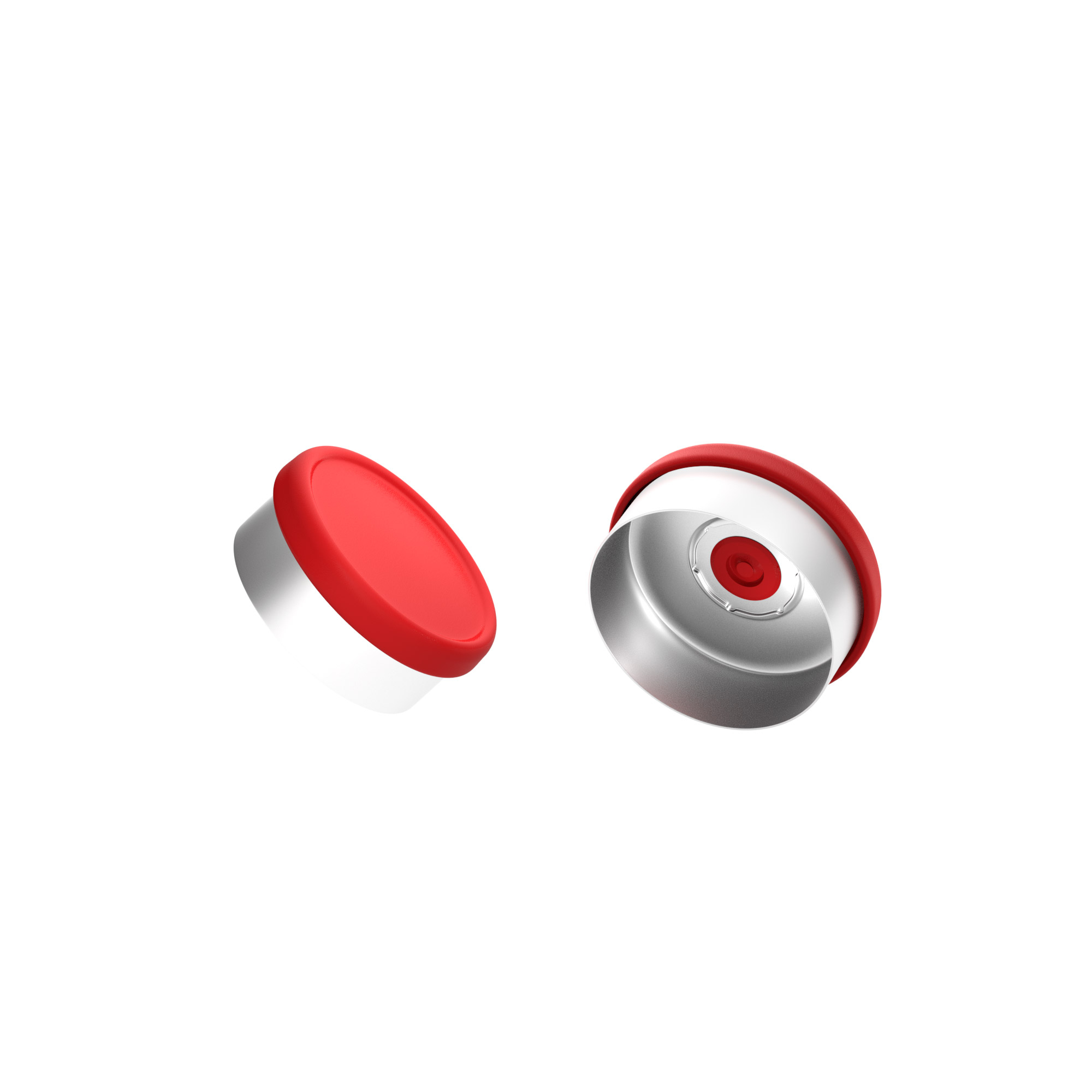

(smartlink: primecap) are Datwyler’s solution for flawless machineability on high-speed filling lines. All of the company’s facilities worldwide deliver PrimeCap™ in the same quality and with all existing specifications, including: highest quality alloy, 13 and 20 mm in five standard aluminum colors, center-gated disc for enhanced machineability, available in 40 standard colors, matte and glossy, with an optimized design: straight skirt edge (Accurim).

pdf,

2.43 MB

jpg,

114.81 KB

Datwyler offers the highest-quality portfolio of prefilled syringe components. Offering a range of sizes, Datwyler’s prefilled syringe components are the ideal solution for a variety of therapeutic needs and are compatible with all standard prefilled syringes on the market.

pdf,

2.43 MB

tif,

1.79 MB

As a thought leader in the industry, Datwyler continuously strives for and accelerates innovation. In doing so, the company enables its customers to bring the most advanced and in-demand products to the worldwide market. Datwyler offers a suite of services designed to promote product safety and efficacy, secure a safe and fast regulatory approval, and ensure a path towards future growth. Datwyler’s four service fields provide a comprehensive solution for primary and secondary packaging needs: lab testing, custom product design, simulations: Finite Element Analysis (FEA), and business continuity plans.

pdf,

2.43 MB

jpg,

214.00 KB

Datwyler is the preferred solution partner to global pharmaceutical companies. Its unique range of products and services includes the most innovative elastomer formulations, coatings, aluminum seals, and processing technologies. Datwyler also offers one of the most extensive product portfolios in the present pharmaceutical and biotech markets worldwide.

pdf,

2.43 MB

tif,

26.84 MB

Datwyler’s most advanced manufacturing standard, FirstLine®, is specially designed to manufacture pharmaceutical rubber components for high-end pharmaceutical and biotech markets in a fully integrated cleanroom environment conforming to the highest industry standards. The FirstLine® manufacturing concept is based on ultra-modern cleanroom technology, automated production cells, fully automated camera inspection, and a unique validated washing process. All facilities aligned with the FirstLine® manufacturing standard are specially designed and operated under a zero-defect philosophy.

pdf,

5.89 MB

jpg,

348.59 KB

The pharmaceutical and biotech markets require high-end quality without compromise. As a Swiss-based, leading supplier and key player in the global healthcare industry, Datwyler is a global thought leader with more than 100 years of experience and a good intuition for future trends.

pdf,

5.89 MB

tif,

13.91 MB

As a leading industrial supplier and a key player in the global healthcare industry, Datwyler possesses a deep knowledge of different healthcare products, which allows them to understand the functions and applications of the customers’ individual products. To meet the individual product needs, Datwyler offers the ability to develop custom products that are ideal for each customers’ drug product.

pdf,

5.89 MB

tif,

12.49 MB

Datwyler’s fluoropolymer spray coating technology is the response to the healthcare market’s ever-increasing demands for better packaging solutions. Datwyler’s coated components provide exceptional container closure integrity, lowest interaction potential, uncompromised quality, and outstanding machineability to biotech, traditional pharma, and generic products.

pdf,

5.89 MB

jpg,

30.50 KB

Datwyler offers a comprehensive product portfolio and the most experience and knowledge in the cartridge applications industry, including solutions for dental treatments, insulin management, and other pharmaceutical and biotech therapies. Datwyler’s cartridge packaging solutions are compatible with all types of glass cartridges and secondary delivery devices in different nominal capacities and dimensions from 1 to 3 ml.

pdf,

5.89 MB

tif,

1.75 MB

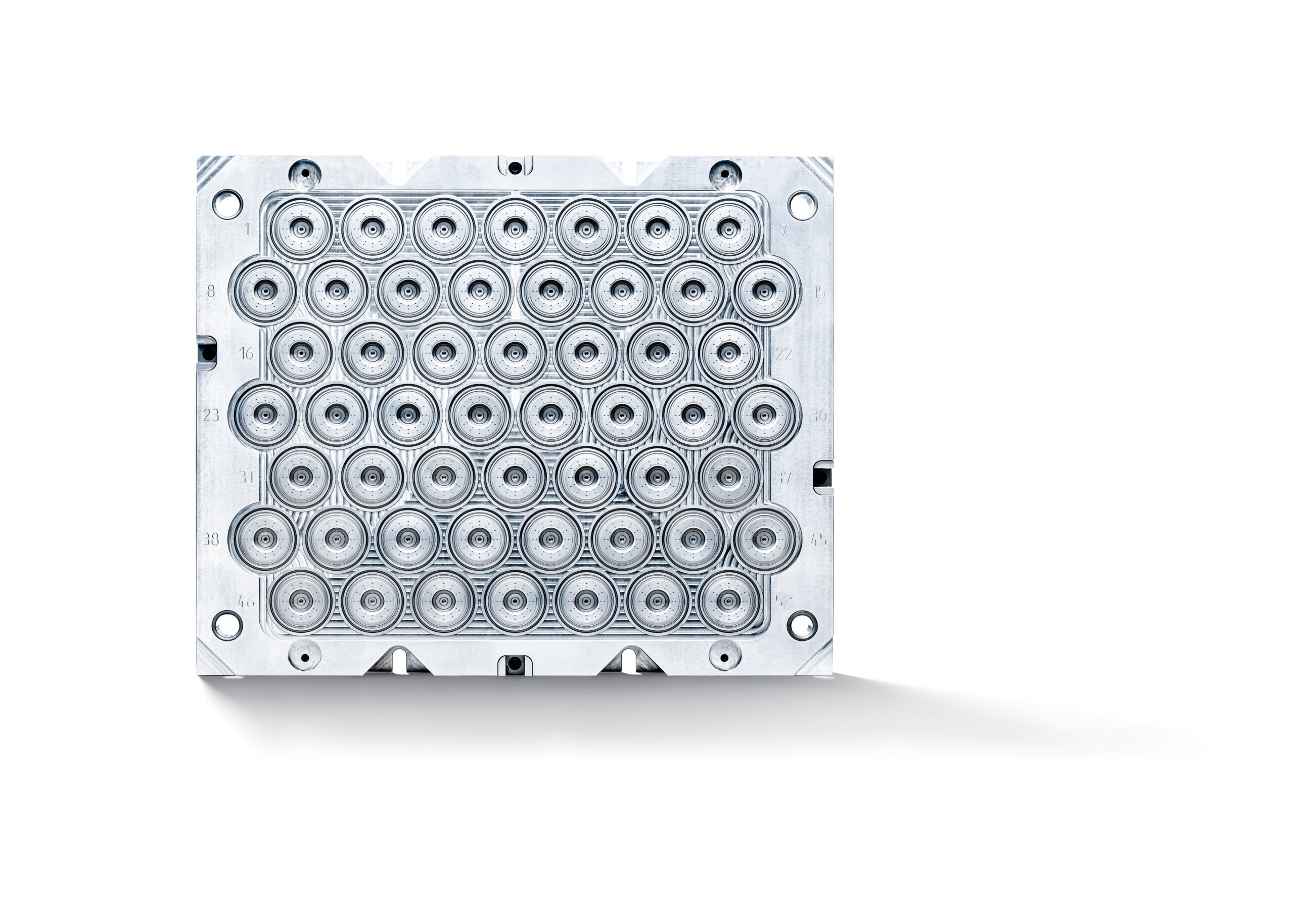

Datwyler’s (smartlink: firstline) concept includes high-level camera inspection to detect and remove defects before Datwyler’s products are packed and shipped to its customers.

pdf,

5.89 MB

tif,

12.65 MB

Datwyler operates a state-of-the-art healthcare plant in the USA (Middletown, Delaware).

pdf,

5.89 MB

jpg,

645.58 KB

The quality of a liquid drug is only ever as good as the quality of its closure. Awareness of this simple yet important fact is what drives the ongoing further development of elastomeric, plastic and aluminium closures at Datwyler. It also ensures that top-quality drugs can be administered rapidly when a medical emergency occurs.

pdf,

5.89 MB

jpg,

383.03 KB

Division

Industrial

High-performance Polymer Components for Powertrain. Spark Plug Boot.

pdf,

5.89 MB

jpg,

99.34 KB

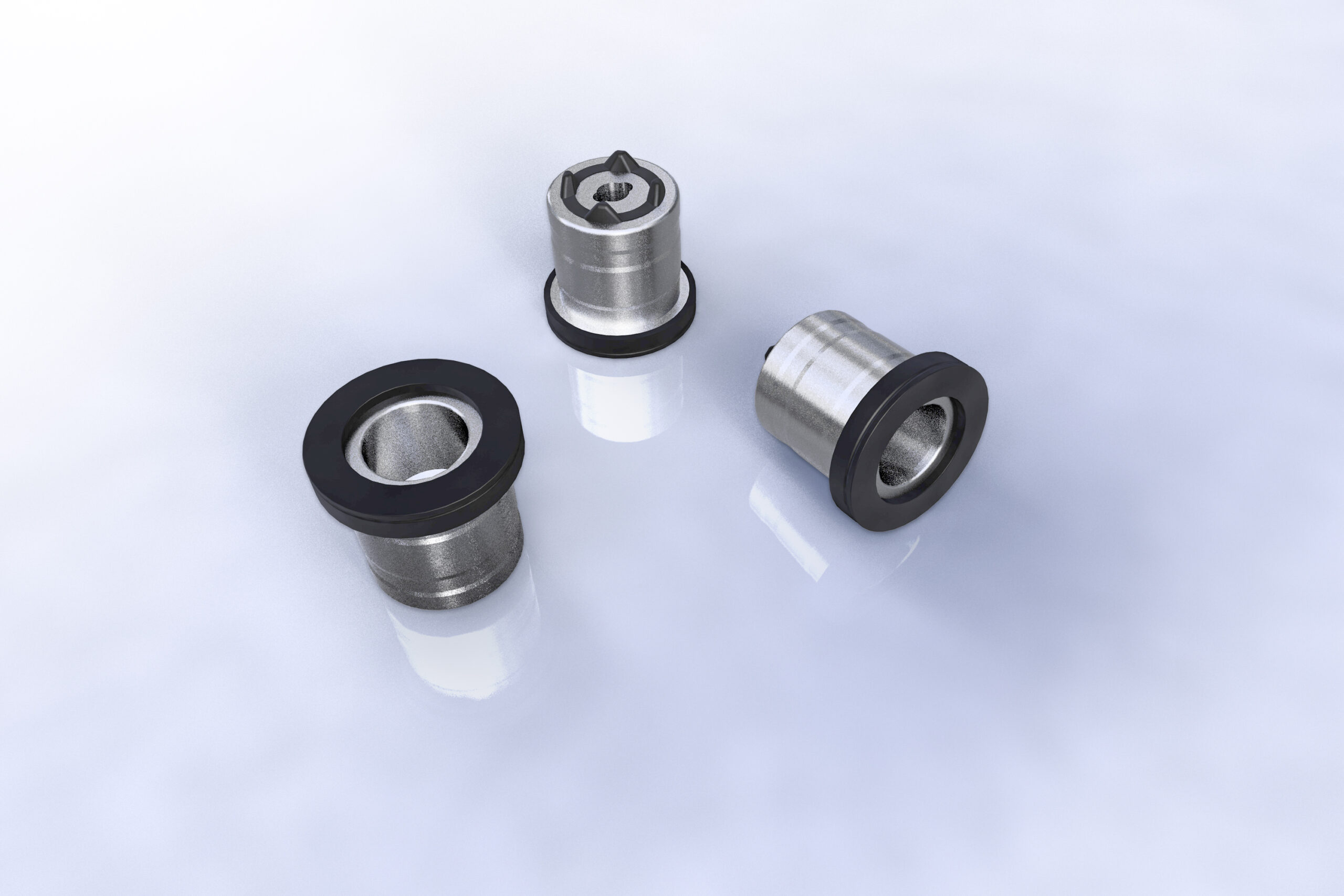

High-performance Polymer Components using various materials. A sample of O-rings for numerous markets.

pdf,

5.89 MB

jpg,

166.22 KB

A sample of high performance polymer membranes and components for numerous applications.

pdf,

5.89 MB

jpg,

177.43 KB

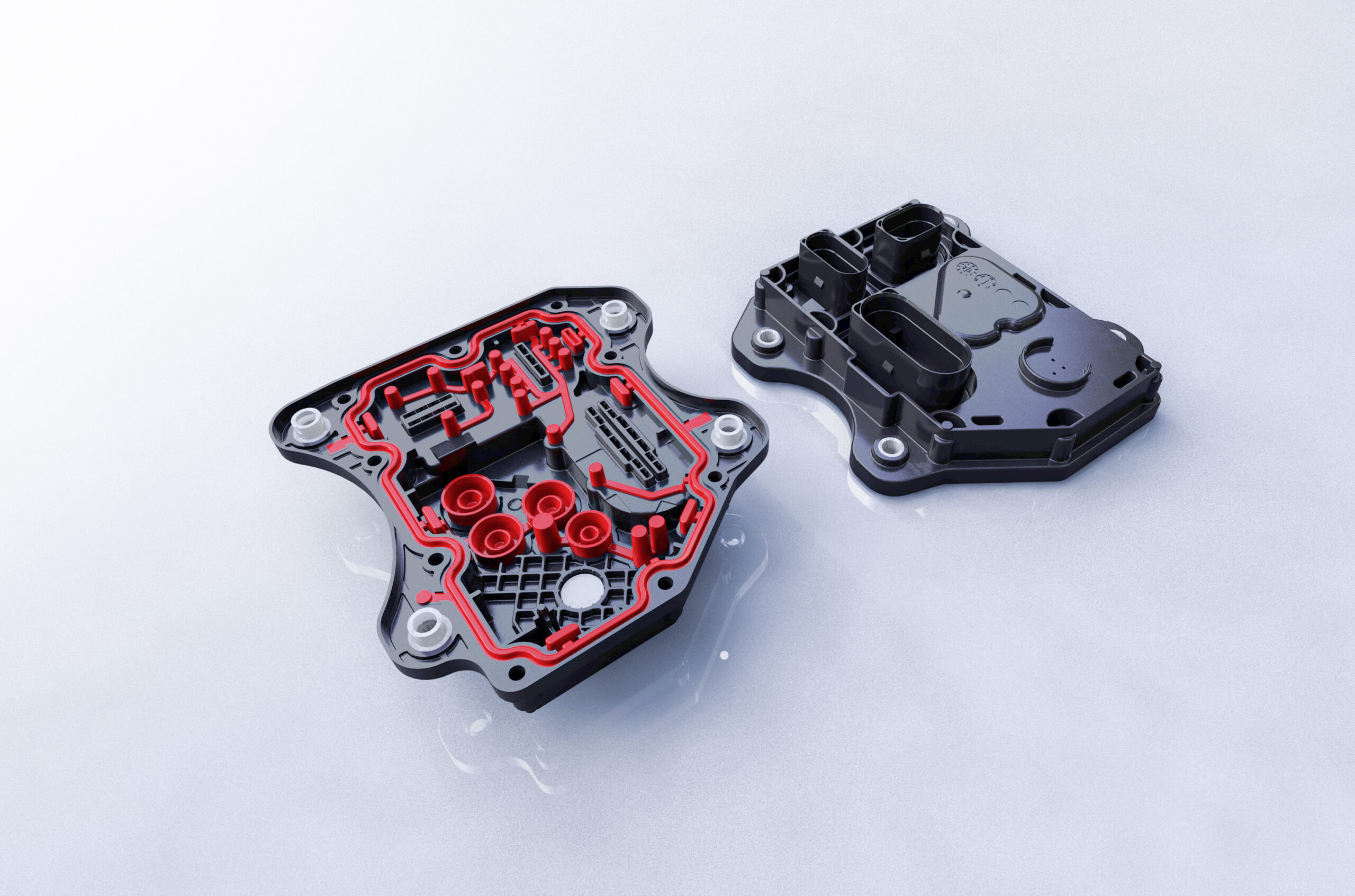

To meet the significantly increasing cleanliness requirements in the mobility industry, Datwyler developed the new production layout «Lean & Clean» in Schattdorf, Switzerland.

pdf,

5.89 MB

jpg,

975.89 KB

State-of-the-art injection molding machines for O-rings production available globally (Europe, Asia, Americas).

pdf,

5.89 MB

jpg,

1.09 MB

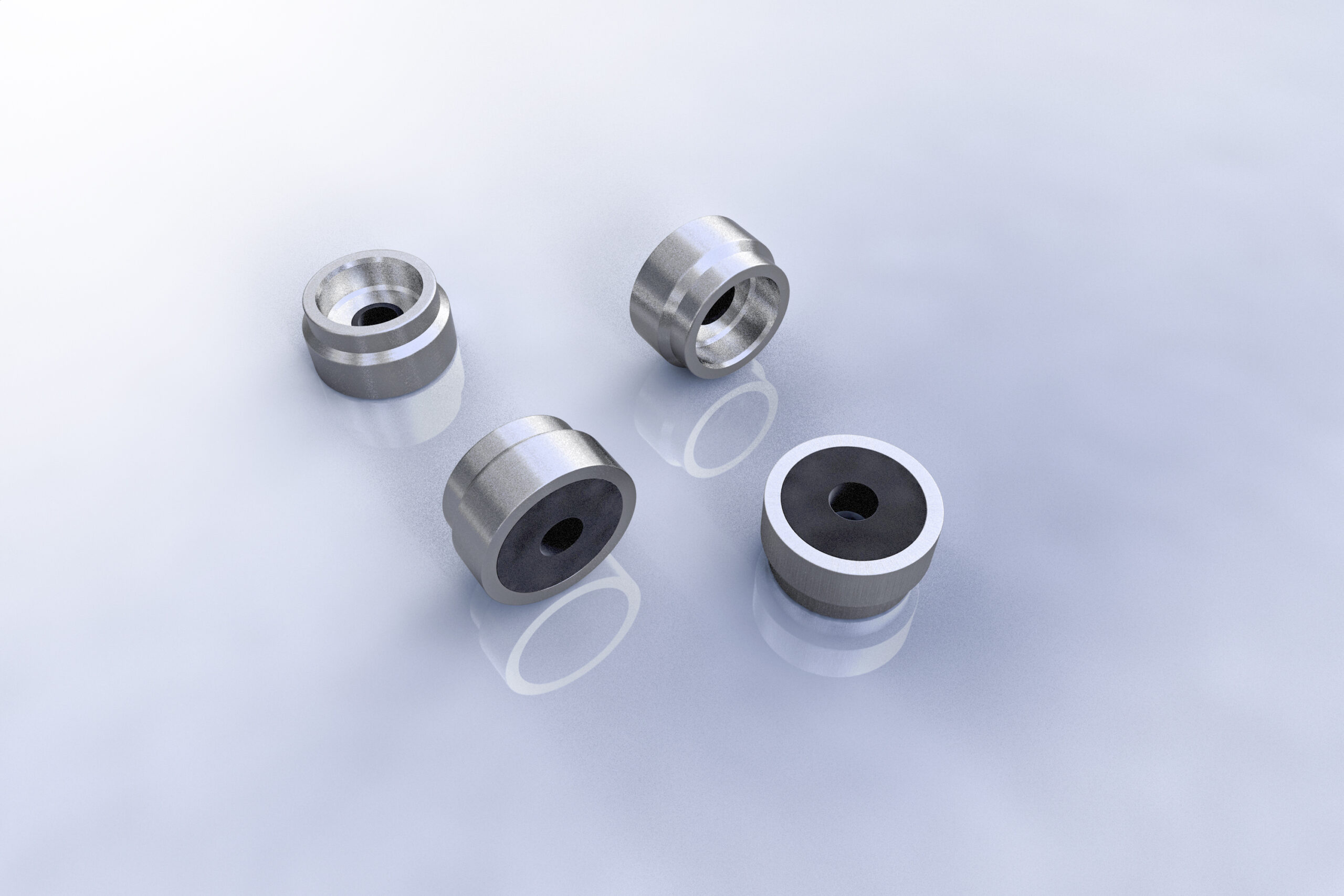

Datwyler’s in-house mold shop enables the company in developing customer-specific tool concepts and meet highest quality standards.

pdf,

5.89 MB

jpg,

518.44 KB

High-performance Polymer Components. Manifold for Power Tools.

pdf,

5.89 MB

jpg,

198.32 KB

High-performance Polymer Components using various materials. A sample of gaskets for numerous markets

pdf,

5.89 MB

jpg,

192.78 KB

High-performance Polymer Components for Fuel Systems. Sealing Disc.

pdf,

5.89 MB

jpg,

268.55 KB

High-performance Polymer Components for Emission Reduction Systems. SCR (selective catalytic reduction) Fork.

pdf,

5.89 MB

jpg,

315.60 KB

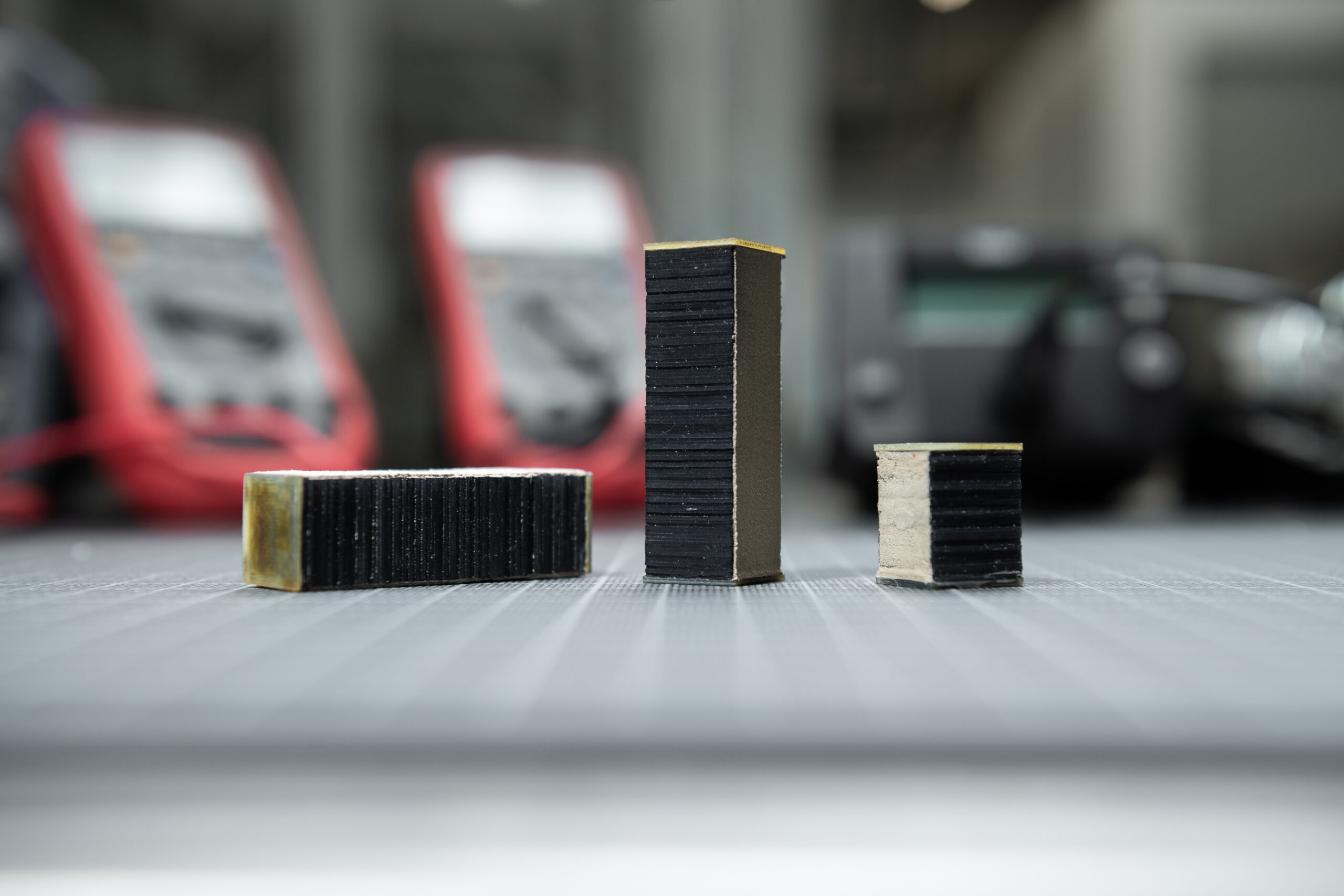

The individualized production of stack actuators represents a unique technical advance.

pdf,

5.89 MB

jpg,

259.76 KB

High-performance Polymer Components for Electrification. Housing.

pdf,

5.89 MB

jpg,

536.71 KB

High-performance Polymer Components for Comfort Systems. Sealing Plunger.

pdf,

5.89 MB

jpg,

225.23 KB

A sample of different coated O-rings for numerous applications.

pdf,

5.89 MB

jpg,

3.84 MB

From efficient factory designs and layouts to reliable and future-proof technologies, all processes are monitored and scrutinized to the highest possible degree.

pdf,

5.89 MB

jpg,

691.36 KB

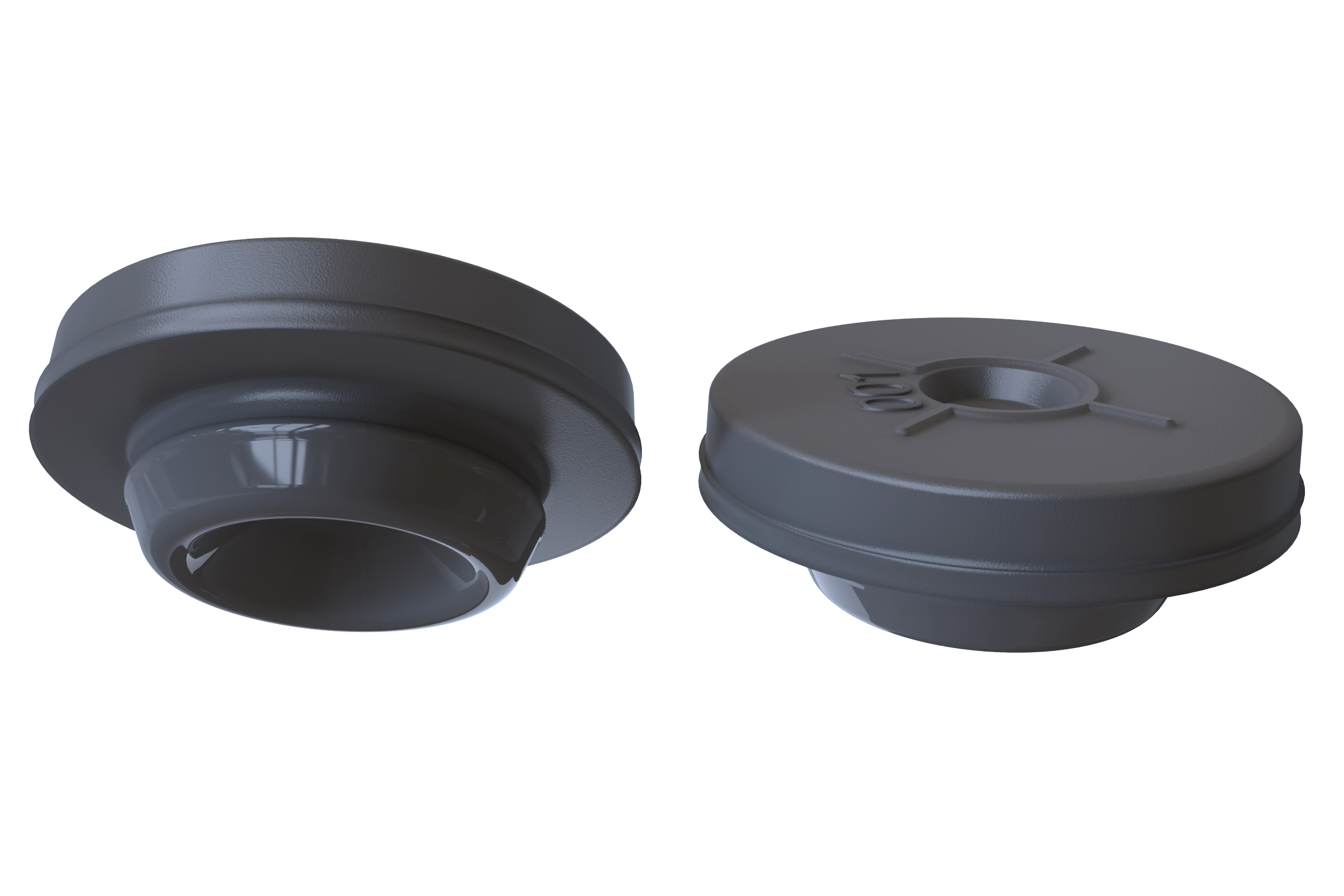

High-performance Polymer Components for Advanced Driver Assistance Systems. Camera Cap.

pdf,

5.89 MB

jpg,

102.94 KB

Highly automated production for the Food & Beverage business unit at Datwyler’s Swiss plant in Schattdorf.

pdf,

5.89 MB

jpg,

624.73 KB

Highly automated production for the Food & Beverage business unit at Datwyler’s Swiss plant in Schattdorf.

pdf,

5.89 MB

jpg,

495.56 KB

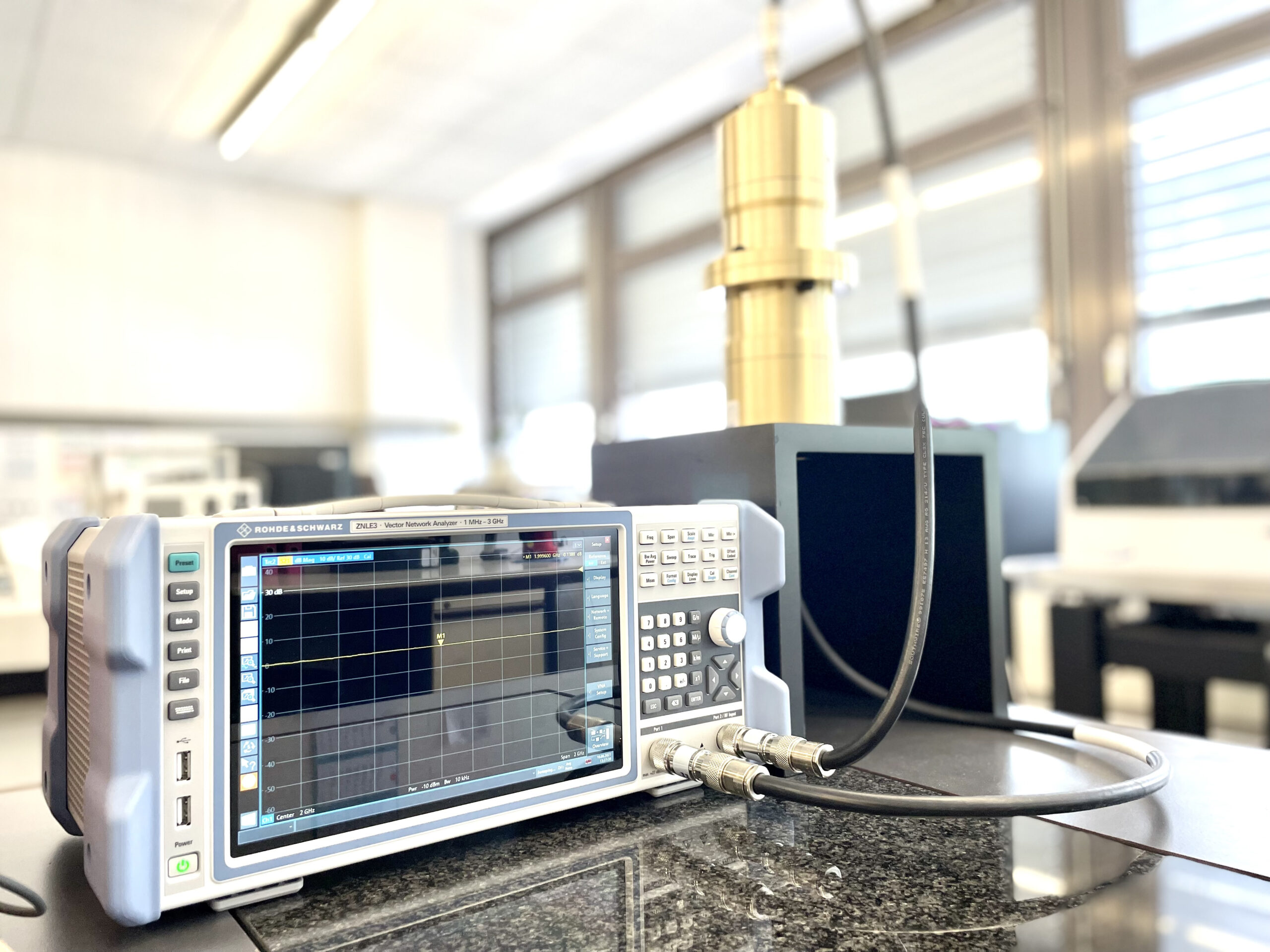

Testing cell for measuring electromagnetic shielding effectiveness according to ASTM D4935-18 at Datwyler lab.

pdf,

5.89 MB

jpg,

562.87 KB

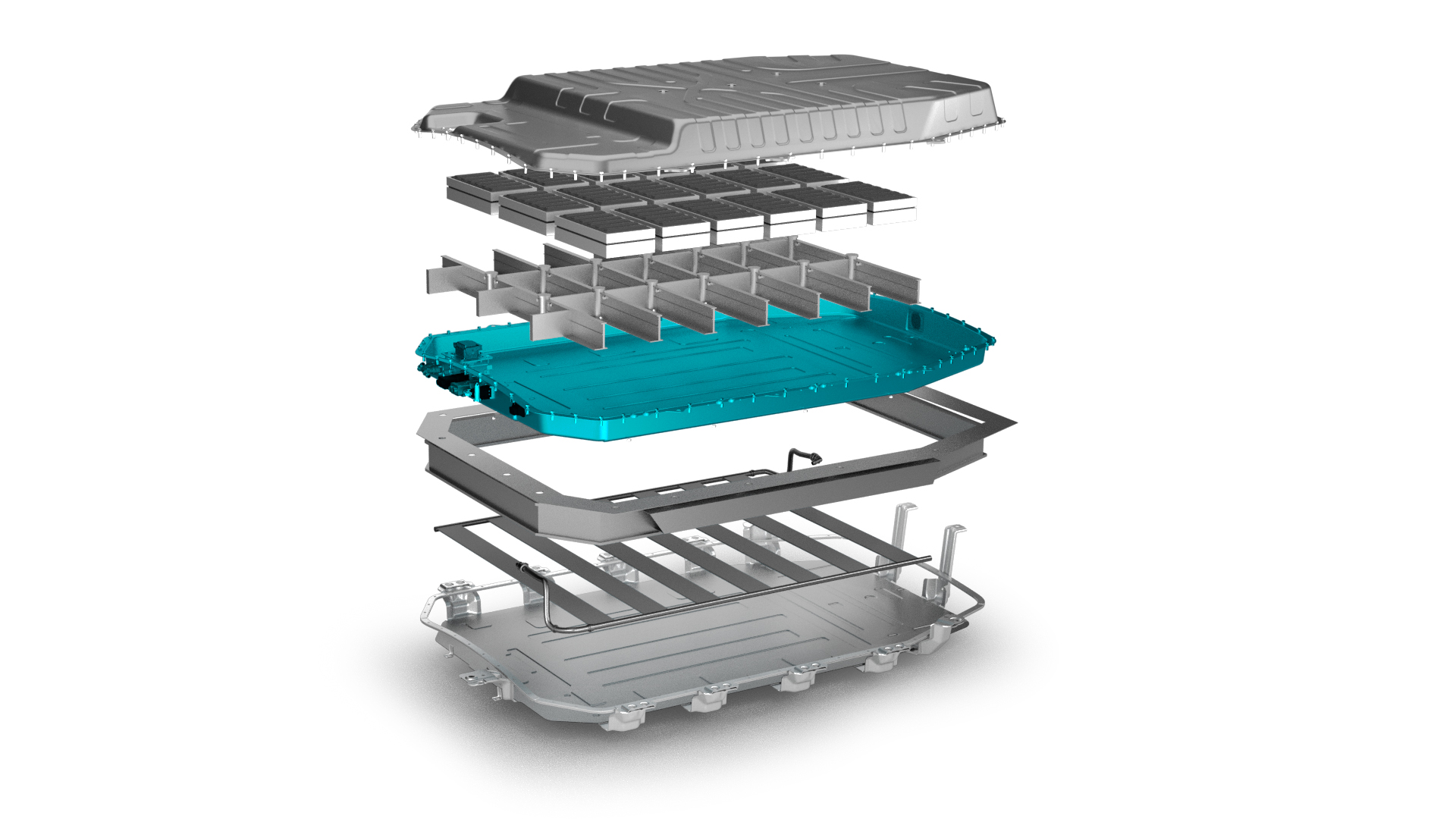

An example of a seal in battery pack produced with thermally conductive elastomer material.

pdf,

5.89 MB

jpg,

535.19 KB

Through operating its own mixing plants, Datwyler has at its disposal the know-how to develop and manufacture all elastomer compounds in-house.

pdf,

5.89 MB

jpg,

2.12 MB

Thanks to advanced simulation techniques, Datwyler is able to support the customer from the early development stage to serial production.

pdf,

5.89 MB

jpg,

713.05 KB

The headoffice of the Division Industrial is located in Schattdorf, Switzerland.

pdf,

5.89 MB

jpg,

0.99 MB

Datwyler’s experts in compression, injection, and transfer molding are able to provide a manufacturing process customized to the individual technical requirements of a customer product.

pdf,

5.89 MB

jpg,

768.61 KB

Enquiry

We keep our media library current. If you are still not able to find a picture or are

unsure whether you can use it for your purposes, please get in touch with us. All

images and videos are intended for editorial use only.