Physics of Rubber Friction

Article | November 20, 2023

Understanding and controlling drag forces greatly affects a seal’s performance whether it is for drive systems in mobility industries or O-ring setting in general applications. Surface interactions are part of the technical knowledge for material modelling and selection of compounds in the Datwyler portfolio.

Whether it is for seal setting, dynamic seals lifetime extension, or fluid percolation minimisation, a clear understanding of the frictional behaviour and interaction of the rubber against the sealing surface is key.

The drag force is directly correlated to contact area between the bodies. This particular contribution comes from one surface adhering to the other, when not under the presence of a lubricant. To understand the adhesional contribution to friction, the concept of real area of contact is most important. The apparent contact area of a seal can easily be calculated by observing the geometry of contact, but to understand how much of this initial calculation is actually interacting with the rubber, surface roughness analysis must be done in tandem with the rubber’s intrinsic properties.

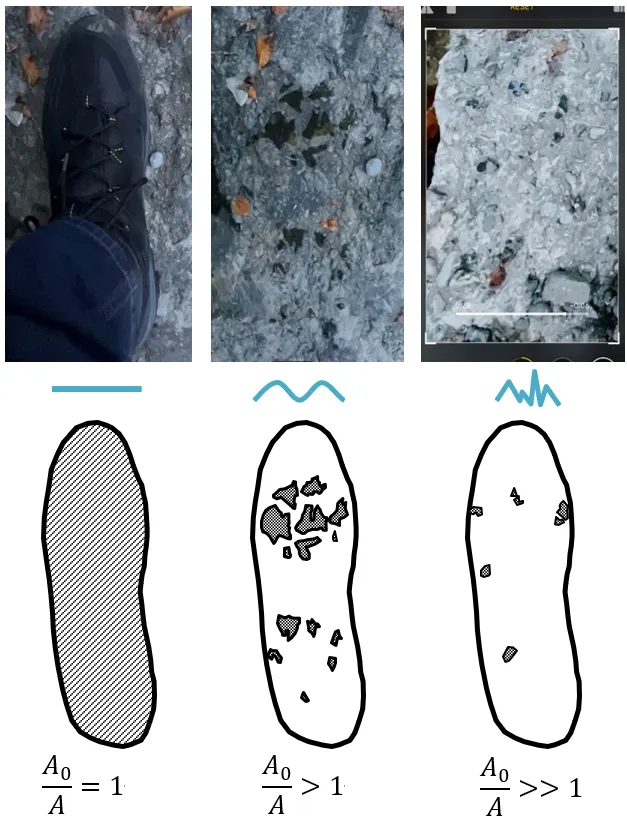

Taking the example of a shoeprint, where the entire shape of the shoe would be the nominal contact area(A0). With an ideally flat surface, the rubber sole would completely cover the shape. As the surface roughens, the real contact (A)area begins to show as just a fraction of the idea represented in the figure with wet footprint marks.

Figure 1: Apparent vs. real contact area

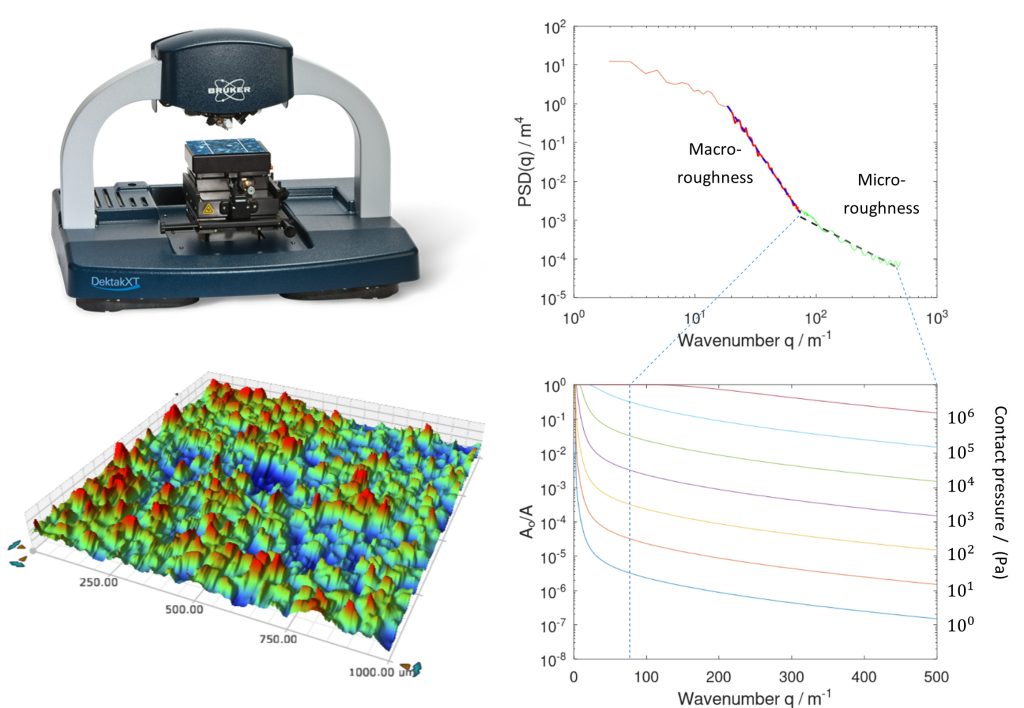

Tribological models can be applied to predict the real contact between interacting bodies. The particular challenge, present in rubber contact analysis is how small changes in temperature, velocity and sealing pressure can have drastic effects. A precise characterisation of the material along with the surface, allows for power spectrum density (PSD) to show how real zones of contact between a rubber seal and the surface could be orders of magnitude lower than what is initially observed, when looking at the micro-roughness scales in particular.

Rubbers are flexible enough to interact with the micro-roughness scale of a surface. Figure 2 shows the profilometry analysis of a randomly rough surface. Once the PSD analysis is done, changes of contact are related to pressure begin to arise. Depending on the applied pressure of the application, contact area can vary between one tenth, and up to one millionth of the nominal (apparent) contact area.

Once understood, the rubber-substrate interaction can be manipulated via compound recipe adjustment. Alternating carbon black and silica as fillers in tyres to adapt to summer or winter conditions is an industry staple, sealing rubbers are no different. From material stiffness to self-lubricating fillers, compound development is a place of privilege when it comes to frictional behaviour manipulation.

Deep exploration of rubber frictional behaviour, both in a theoretical, and experimental approach, is an ambitious project. The challenges presented by the subject are welcomed by the Datwyler development team. With the capabilities of the novel Technology & Innovation labs, precise description of various surfaces can be obtained. This will only improve our understanding of the seal’s behaviour and allow us to better design custom solutions for our clients.

author

Eduardo Yanes Nunez

Manager Material Development

Innovation & Design