Datwyler patents sustainable cellulose-based fillers

News | October 25, 2022

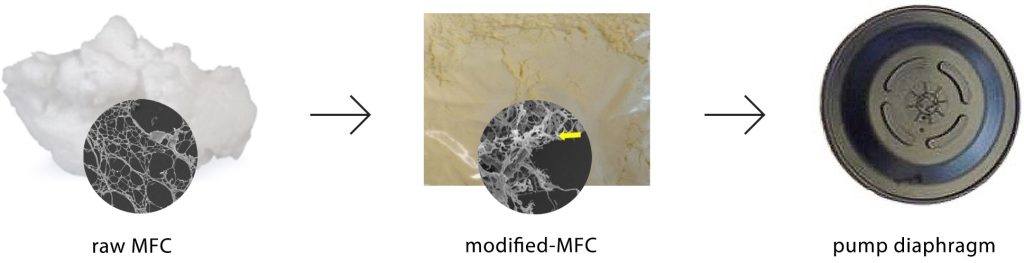

Datwyler, together with the development partner Empa, has developed and patented an industrial process for surface modification of microfibrillated cellulose (MFC). The modified MFC can be used to substitute petroleum-based aramid fibers as fillers in elastomer compounds. Fillers derived from organic cellulose increase the sustainability of elastomer products.

The substitution of petrochemical-based materials with renewable ones is an important step towards increasing sustainability. Materials derived from organic cellulose are promising candidates for this scope. These materials are renewable, abundant, and show a low environmental impact.

Successful development project by Datwyler and Empa

In the rubber industry, microfibrillated cellulose (MFC) received much attention given the high stiffness, fibrils morphology, low density and mechanical properties. It thus has a high potential to improve the properties of elastomer compounds.However, the successful use of such material in water repellent elastomers is challenging. Together with the development partner Empa (Swiss Federal Laboratories for Materials Science and Technology), Datwyler developed an industrial process for the surface modification of MFC to solve this challenge.

Patented process as basis for industrial implementation

First trials envisioned the substitution of aramid fibers with modified MFCs. The results show good compatibility between the MFC-filler and the elastomer matrix with strong reinforcing effect, even superior to those reached with conventional petroleum-based fibers. Based on these promising research results, Datwyler has patented the process and will work on its implementation for industrial mass production in the next phase. The development of these novel cellulose-based fillers will result in an important step towards increasing sustainability in elastomer products such as pump diaphragms.

Anfragen

Guido Unternährer

VP Financial Communication & Investor Relations

Read further media releases on this topic from Empa and the German Rubber Manufacturers Association (WDK).